Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

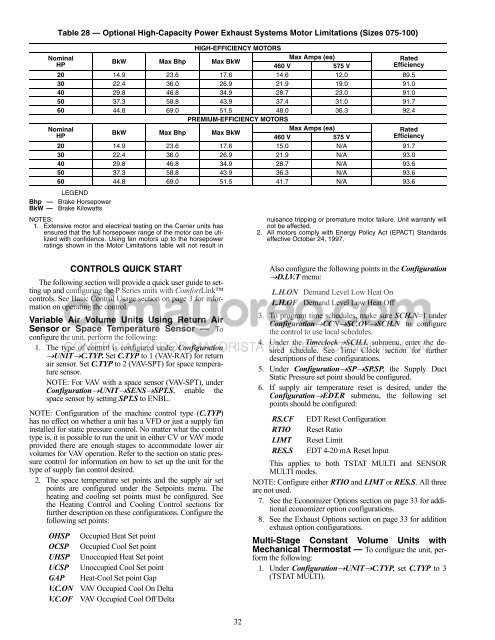

Table 28 — Optional High-Capacity Power Exhaust Systems Motor Limitations (Sizes 075-100)<br />

HIGH-EFFICIENCY MOTORS<br />

Nominal<br />

HP<br />

BkW Max Bhp Max BkW<br />

Max Amps (ea)<br />

460 V 575 V<br />

Rated<br />

Efficiency<br />

20 14.9 23.6 17.6 14.6 12.0 89.5<br />

30 22.4 36.0 26.9 21.9 19.0 91.0<br />

40 29.8 46.8 34.9 28.7 23.0 91.0<br />

50 37.3 58.8 43.9 37.4 31.0 91.7<br />

60 44.8 69.0 51.5 48.0 36.3 92.4<br />

PREMIUM-EFFICIENCY MOTORS<br />

Nominal<br />

HP<br />

BkW Max Bhp Max BkW<br />

Max Amps (ea)<br />

460 V 575 V<br />

Rated<br />

Efficiency<br />

20 14.9 23.6 17.6 15.0 N/A 91.7<br />

30 22.4 36.0 26.9 21.9 N/A 93.0<br />

40 29.8 46.8 34.9 28.7 N/A 93.6<br />

50 37.3 58.8 43.9 36.3 N/A 93.6<br />

60 44.8 69.0 51.5 41.7 N/A 93.6<br />

Bhp —<br />

LEGEND<br />

Brake Horsepower<br />

BkW — Brake Kilowatts<br />

NOTES:<br />

1. Extensive motor <strong>and</strong> electrical testing on the Carrier units has<br />

ensured that the full horsepower range of the motor can be utilized<br />

with confidence. Using fan motors up to the horsepower<br />

ratings shown in the Motor Limitations table will not result in<br />

CONTROLS QUICK START<br />

The following section will provide a quick user guide to setting<br />

up <strong>and</strong> configuring the P Series units with ComfortLink<br />

controls. See Basic Control Usage section on page 3 for information<br />

on operating the control.<br />

Variable Air Volume Units Using Return Air<br />

Sensor or Space Temperature Sensor — To<br />

configure the unit, perform the following:<br />

1. The type of control is configured under Configuration<br />

UNITC.TYP. Set C.TYP to 1 (VAV-RAT) for return<br />

air sensor. Set C.TYP to 2 (VAV-SPT) for space temperature<br />

sensor.<br />

NOTE: For VAV with a space sensor (VAV-SPT), under<br />

ConfigurationUNITSENSSPT.S, enable the<br />

space sensor by setting SPT.S to ENBL.<br />

NOTE: Configuration of the machine control type (C.TYP)<br />

has no effect on whether a unit has a VFD or just a supply fan<br />

installed for static pressure control. No matter what the control<br />

type is, it is possible to run the unit in either CV or VAV mode<br />

provided there are enough stages to accommodate lower air<br />

volumes for VAV operation. Refer to the section on static pressure<br />

control for information on how to set up the unit for the<br />

type of supply fan control desired.<br />

2. The space temperature set points <strong>and</strong> the supply air set<br />

points are configured under the Setpoints menu. The<br />

heating <strong>and</strong> cooling set points must be configured. See<br />

the Heating Control <strong>and</strong> Cooling Control sections for<br />

further description on these configurations. Configure the<br />

following set points:<br />

OHSP Occupied Heat Set point<br />

OCSP Occupied Cool Set point<br />

UHSP Unoccupied Heat Set point<br />

UCSP Unoccupied Cool Set point<br />

GAP Heat-Cool Set point Gap<br />

V.C.ON VAV Occupied Cool On Delta<br />

V.C.OF VAV Occupied Cool Off Delta<br />

32<br />

nuisance tripping or premature motor failure. Unit warranty will<br />

not be affected.<br />

2. All motors comply with Energy Policy Act (EPACT) St<strong>and</strong>ards<br />

effective October 24, 1997.<br />

Also configure the following points in the Configuration<br />

D.LV.T menu:<br />

L.H.ON Dem<strong>and</strong> Level Low Heat On<br />

L.H.OF Dem<strong>and</strong> Level Low Heat Off<br />

3. To program time schedules, make sure SCH.N=1 under<br />

ConfigurationCCNSC.OVSCH.N to configure<br />

the control to use local schedules.<br />

4. Under the TimeclockSCH.L submenu, enter the desired<br />

schedule. See Time Clock section for further<br />

descriptions of these configurations.<br />

5. Under ConfigurationSPSP.SP, the Supply Duct<br />

Static Pressure set point should be configured.<br />

6. If supply air temperature reset is desired, under the<br />

ConfigurationEDT.R submenu, the following set<br />

points should be configured:<br />

RS.CF EDT Reset Configuration<br />

RTIO Reset Ratio<br />

LIMT Reset Limit<br />

RES.S EDT 4-20 mA Reset Input<br />

This applies to both TSTAT MULTI <strong>and</strong> SENSOR<br />

MULTI modes.<br />

NOTE: Configure either RTIO <strong>and</strong> LIMT or RES.S. All three<br />

are not used.<br />

7. See the Economizer Options section on page 33 for additional<br />

economizer option configurations.<br />

8. See the Exhaust Options section on page 33 for addition<br />

exhaust option configurations.<br />

Multi-Stage Constant Volume Units with<br />

Mechanical Thermostat — To configure the unit, perform<br />

the following:<br />

1. Under ConfigurationUNITC.TYP, set C.TYP to 3<br />

(TSTAT MULTI).