Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

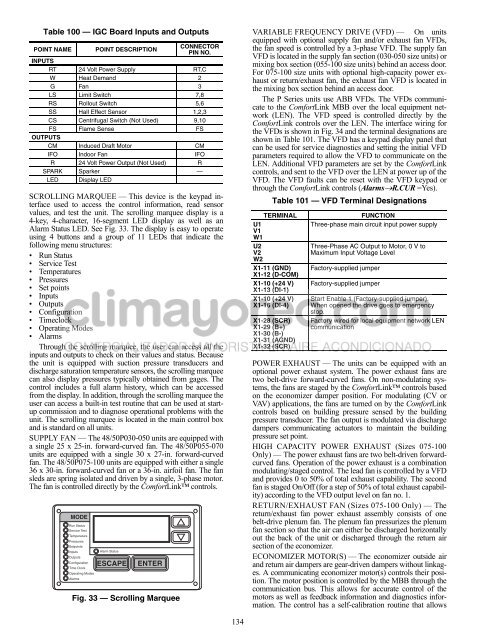

Table 100 — IGC Board Inputs <strong>and</strong> Outputs<br />

POINT NAME<br />

INPUTS<br />

POINT DESCRIPTION<br />

CONNECTOR<br />

PIN NO.<br />

RT 24 Volt Power Supply RT,C<br />

W Heat Dem<strong>and</strong> 2<br />

G Fan 3<br />

LS Limit Switch 7,8<br />

RS Rollout Switch 5,6<br />

SS Hall Effect Sensor 1,2,3<br />

CS Centrifugal Switch (Not Used) 9,10<br />

FS<br />

OUTPUTS<br />

Flame Sense FS<br />

CM Induced Draft Motor CM<br />

IFO Indoor Fan IFO<br />

R 24 Volt Power Output (Not Used) R<br />

SPARK Sparker —<br />

LED Display LED<br />

SCROLLING MARQUEE — This device is the keypad interface<br />

used to access the control information, read sensor<br />

values, <strong>and</strong> test the unit. The scrolling marquee display is a<br />

4-key, 4-character, 16-segment LED display as well as an<br />

Alarm Status LED. See Fig. 33. The display is easy to operate<br />

using 4 buttons <strong>and</strong> a group of 11 LEDs that indicate the<br />

following menu structures:<br />

• Run Status<br />

• <strong>Service</strong> Test<br />

• Temperatures<br />

• Pressures<br />

• Set points<br />

• Inputs<br />

• Outputs<br />

• Configuration<br />

• Timeclock<br />

• Operating Modes<br />

• Alarms<br />

Through the scrolling marquee, the user can access all the<br />

inputs <strong>and</strong> outputs to check on their values <strong>and</strong> status. Because<br />

the unit is equipped with suction pressure transducers <strong>and</strong><br />

discharge saturation temperature sensors, the scrolling marquee<br />

can also display pressures typically obtained from gages. The<br />

control includes a full alarm history, which can be accessed<br />

from the display. In addition, through the scrolling marquee the<br />

user can access a built-in test routine that can be used at startup<br />

commission <strong>and</strong> to diagnose operational problems with the<br />

unit. The scrolling marquee is located in the main control box<br />

<strong>and</strong> is st<strong>and</strong>ard on all units.<br />

SUPPLY FAN — The 48/50P030-050 units are equipped with<br />

a single 25 x 25-in. forward-curved fan. The 48/50P055-070<br />

units are equipped with a single 30 x 27-in. forward-curved<br />

fan. The 48/50P075-100 units are equipped with either a single<br />

36 x 30-in. forward-curved fan or a 36-in. airfoil fan. The fan<br />

sleds are spring isolated <strong>and</strong> driven by a single, 3-phase motor.<br />

The fan is controlled directly by the ComfortLink controls.<br />

MODE<br />

Run Status<br />

<strong>Service</strong> Test<br />

Temperature<br />

Pressures<br />

Setpoints<br />

Inputs<br />

Outputs<br />

Configuration<br />

Time Clock<br />

Operating Modes<br />

Alarms<br />

Alarm Status<br />

ESCAPE<br />

ENTER<br />

Fig. 33 — Scrolling Marquee<br />

134<br />

VARIABLE FREQUENCY DRIVE (VFD) — On units<br />

equipped with optional supply fan <strong>and</strong>/or exhaust fan VFDs,<br />

the fan speed is controlled by a 3-phase VFD. The supply fan<br />

VFD is located in the supply fan section (030-050 size units) or<br />

mixing box section (055-100 size units) behind an access door.<br />

For 075-100 size units with optional high-capacity power exhaust<br />

or return/exhaust fan, the exhaust fan VFD is located in<br />

the mixing box section behind an access door.<br />

The P Series units use ABB VFDs. The VFDs communicate<br />

to the ComfortLink MBB over the local equipment network<br />

(LEN). The VFD speed is controlled directly by the<br />

ComfortLink controls over the LEN. The interface wiring for<br />

the VFDs is shown in Fig. 34 <strong>and</strong> the terminal designations are<br />

shown in Table 101. The VFD has a keypad display panel that<br />

can be used for service diagnostics <strong>and</strong> setting the initial VFD<br />

parameters required to allow the VFD to communicate on the<br />

LEN. Additional VFD parameters are set by the ComfortLink<br />

controls, <strong>and</strong> sent to the VFD over the LEN at power up of the<br />

VFD. The VFD faults can be reset with the VFD keypad or<br />

through the ComfortLink controls (AlarmsR.CUR =Yes).<br />

Table 101 — VFD Terminal Designations<br />

TERMINAL FUNCTION<br />

U1 Three-phase main circuit input power supply<br />

V1<br />

W1<br />

U2 Three-Phase AC Output to Motor, 0 V to<br />

V2<br />

Maximum Input Voltage Level<br />

W2<br />

X1-11 (GND) Factory-supplied jumper<br />

X1-12 (D-COM)<br />

X1-10 (+24 V) Factory-supplied jumper<br />

X1-13 (DI-1)<br />

X1-10 (+24 V) <strong>Start</strong> Enable 1 (Factory-supplied jumper).<br />

X1-16 (DI-4) When opened the drive goes to emergency<br />

stop.<br />

X1-28 (SCR) Factory wired for local equipment network LEN<br />

X1-29 (B+) communication<br />

X1-30 (B-)<br />

X1-31 (AGND)<br />

X1-32 (SCR)<br />

POWER EXHAUST — The units can be equipped with an<br />

optional power exhaust system. The power exhaust fans are<br />

two belt-drive forward-curved fans. On non-modulating systems,<br />

the fans are staged by the ComfortLink controls based<br />

on the economizer damper position. For modulating (CV or<br />

VAV) applications, the fans are turned on by the ComfortLink<br />

controls based on building pressure sensed by the building<br />

pressure transducer. The fan output is modulated via discharge<br />

dampers communicating actuators to maintain the building<br />

pressure set point.<br />

HIGH CAPACITY POWER EXHAUST (Sizes 075-100<br />

Only) — The power exhaust fans are two belt-driven forwardcurved<br />

fans. <strong>Operation</strong> of the power exhaust is a combination<br />

modulating/staged control. The lead fan is controlled by a VFD<br />

<strong>and</strong> provides 0 to 50% of total exhaust capability. The second<br />

fan is staged On/Off (for a step of 50% of total exhaust capability)<br />

according to the VFD output level on fan no. 1.<br />

RETURN/EXHAUST FAN (Sizes 075-100 Only) — The<br />

return/exhaust fan power exhaust assembly consists of one<br />

belt-drive plenum fan. The plenum fan pressurizes the plenum<br />

fan section so that the air can either be discharged horizontally<br />

out the back of the unit or discharged through the return air<br />

section of the economizer.<br />

ECONOMIZER MOTOR(S) — The economizer outside air<br />

<strong>and</strong> return air dampers are gear-driven dampers without linkages.<br />

A communicating economizer motor(s) controls their position.<br />

The motor position is controlled by the MBB through the<br />

communication bus. This allows for accurate control of the<br />

motors as well as feedback information <strong>and</strong> diagnostics information.<br />

The control has a self-calibration routine that allows