Effet chez le porcelet d'une exposition à un régime co-contaminé en ...

Effet chez le porcelet d'une exposition à un régime co-contaminé en ...

Effet chez le porcelet d'une exposition à un régime co-contaminé en ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

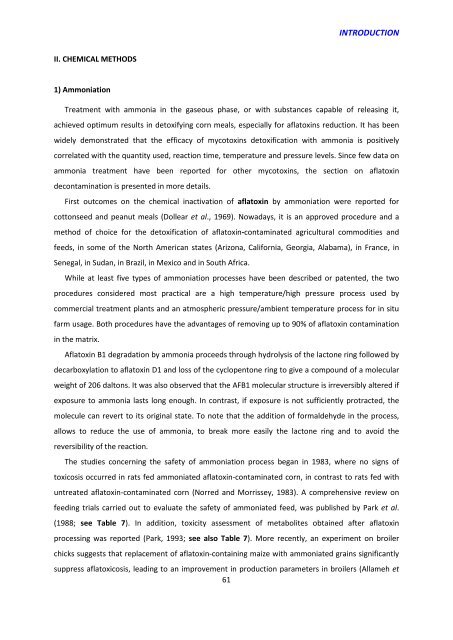

INTRODUCTIONII. CHEMICAL METHODS1) AmmoniationTreatm<strong>en</strong>t with ammonia in the gaseous phase, or with substances capab<strong>le</strong> of re<strong>le</strong>asing it,achieved optimum results in detoxifying <strong>co</strong>rn meals, especially for aflatoxins reduction. It has be<strong>en</strong>widely demonstrated that the efficacy of my<strong>co</strong>toxins detoxification with ammonia is positively<strong>co</strong>rrelated with the quantity used, reaction time, temperature and pressure <strong>le</strong>vels. Since few data onammonia treatm<strong>en</strong>t have be<strong>en</strong> reported for other my<strong>co</strong>toxins, the section on aflatoxinde<strong>co</strong>ntamination is pres<strong>en</strong>ted in more details.First out<strong>co</strong>mes on the chemical inactivation of aflatoxin by ammoniation were reported for<strong>co</strong>ttonseed and peanut meals (Dol<strong>le</strong>ar et al., 1969). Nowadays, it is an approved procedure and amethod of choice for the detoxification of aflatoxin-<strong>co</strong>ntaminated agricultural <strong>co</strong>mmodities andfeeds, in some of the North American states (Arizona, California, Georgia, Alabama), in France, inS<strong>en</strong>egal, in Sudan, in Brazil, in Mexi<strong>co</strong> and in South Africa.Whi<strong>le</strong> at <strong>le</strong>ast five types of ammoniation processes have be<strong>en</strong> described or pat<strong>en</strong>ted, the twoprocedures <strong>co</strong>nsidered most practical are a high temperature/high pressure process used by<strong>co</strong>mmercial treatm<strong>en</strong>t plants and an atmospheric pressure/ambi<strong>en</strong>t temperature process for in situfarm usage. Both procedures have the advantages of removing up to 90% of aflatoxin <strong>co</strong>ntaminationin the matrix.Aflatoxin B1 degradation by ammonia proceeds through hydrolysis of the lactone ring followed bydecarboxylation to aflatoxin D1 and loss of the cyclop<strong>en</strong>tone ring to give a <strong>co</strong>mpo<strong>un</strong>d of a mo<strong>le</strong>cularweight of 206 daltons. It was also observed that the AFB1 mo<strong>le</strong>cular structure is irreversibly altered ifexposure to ammonia lasts long <strong>en</strong>ough. In <strong>co</strong>ntrast, if exposure is not suffici<strong>en</strong>tly protracted, themo<strong>le</strong>cu<strong>le</strong> can revert to its original state. To note that the addition of formaldehyde in the process,allows to reduce the use of ammonia, to break more easily the lactone ring and to avoid thereversibility of the reaction.The studies <strong>co</strong>ncerning the safety of ammoniation process began in 1983, where no signs oftoxi<strong>co</strong>sis occurred in rats fed ammoniated aflatoxin-<strong>co</strong>ntaminated <strong>co</strong>rn, in <strong>co</strong>ntrast to rats fed with<strong>un</strong>treated aflatoxin-<strong>co</strong>ntaminated <strong>co</strong>rn (Norred and Morrissey, 1983). A <strong>co</strong>mpreh<strong>en</strong>sive review onfeeding trials carried out to evaluate the safety of ammoniated feed, was published by Park et al.(1988; see Tab<strong>le</strong> 7). In addition, toxicity assessm<strong>en</strong>t of metabolites obtained after aflatoxinprocessing was reported (Park, 1993; see also Tab<strong>le</strong> 7). More rec<strong>en</strong>tly, an experim<strong>en</strong>t on broi<strong>le</strong>rchicks suggests that replacem<strong>en</strong>t of aflatoxin-<strong>co</strong>ntaining maize with ammoniated grains significantlysuppress aflatoxi<strong>co</strong>sis, <strong>le</strong>ading to an improvem<strong>en</strong>t in production parameters in broi<strong>le</strong>rs (Allameh et61