- Page 1 and 2:

NAVMC DIR 5100.8SDMay 15, 2006NAVMC

- Page 3 and 4:

NAVMC DIR 5100.8MARINE CORPSOCCUPAT

- Page 6 and 7:

MARCOR OSH PROGRAM MANUALRECORD OF

- Page 8 and 9:

CHAPTERPAGE17 HAZARDOUS MATERIALS C

- Page 11 and 12:

MARCOR OSH PROGRAM MANUALCHAPTER 1I

- Page 13 and 14:

MARCOR OSH PROGRAM MANUAL 10032. Qu

- Page 15 and 16:

MARCOR OSH PROGRAM MANUAL 10041004.

- Page 17:

MARCOR OSH PROGRAM MANUALCHAPTER 2R

- Page 20 and 21:

2000 MARCOR OSH PROGRAM MANUAL(5) I

- Page 22 and 23:

2000 MARCOR OSH PROGRAM MANUALdirec

- Page 24 and 25:

2002 MARCOR OSH PROGRAM MANUAL8. En

- Page 26 and 27:

2003 MARCOR OSH PROGRAM MANUALb. Al

- Page 28 and 29:

2003 MARCOR OSH PROGRAM MANUALappro

- Page 30:

MARCOR OSH PROGRAM MANUALCHAPTER 3S

- Page 33 and 34:

3000 MARCOR OSH PROGRAM MANUALinteg

- Page 35 and 36:

3001 MARCOR OSH PROGRAM MANUALe. On

- Page 37 and 38:

3001 MARCOR OSH PROGRAM MANUALany o

- Page 39:

MARCOR OSH PROGRAM MANUALCHAPTER 4C

- Page 42 and 43:

4001 MARCOR OSH PROGRAM MANUAL3. Pu

- Page 44 and 45:

4002 MARCOR OSH PROGRAM MANUALkept

- Page 47 and 48:

MARCOR OSH PROGRAM MANUALCHAPTER 5T

- Page 49 and 50: MARCOR OSH PROGRAM MANUAL 5001Motor

- Page 51 and 52: MARCOR OSH PROGRAM MANUAL 50017. Sa

- Page 53 and 54: MARCOR OSH PROGRAM MANUAL 5003coord

- Page 56 and 57: MARCOR OSH PROGRAM MANUALCHAPTER 6O

- Page 58 and 59: MARCOR OSH PROGRAM MANUAL 6003explo

- Page 60 and 61: MARCOR OSH PROGRAM MANUAL 6005c. A

- Page 62: MARCOR OSH PROGRAM MANUALCHAPTER 7W

- Page 65 and 66: 7002 MARCOR OSH PROGRAM MANUAL2. In

- Page 67 and 68: 7003 MARCOR OSH PROGRAM MANUALc. Ne

- Page 69 and 70: 7004 MARCOR OSH PROGRAM MANUALe. En

- Page 72 and 73: MARCOR OSH PROGRAM MANUAL 7006any p

- Page 74 and 75: MARCOR OSH PROGRAM MANUAL 70102. Th

- Page 76 and 77: MARCOR OSH PROGRAM MANUALRISK ASSES

- Page 78: MARCOR OSH PROGRAM MANUALCHAPTER 8F

- Page 81 and 82: 8001 MARCOR OSH PROGRAM MANUALLaw 9

- Page 83 and 84: 8003 MARCOR OSH PROGRAM MANUALa. US

- Page 85: MARCOR OSH PROGRAM MANUALCHAPTER 9R

- Page 88 and 89: 9002 MARCOR OSH PROGRAM MANUALadvis

- Page 90 and 91: 9003 MARCOR OSH PROGRAM MANUALThe a

- Page 92 and 93: 9006 MARCOR OSH PROGRAM MANUAL3. Pe

- Page 94 and 95: MARCOR OSH PROGRAM MANUALSAMPLELOG

- Page 96 and 97: MARCOR OSH PROGRAM MANUALDid any of

- Page 99: MARCOR OSH PROGRAM MANUALCHAPTER 10

- Page 103 and 104: MARCOR OSH PROGRAM MANUAL 100032. D

- Page 105: MARCOR OSH PROGRAM MANUALCHAPTER 11

- Page 108 and 109: 11001 MARCOR OSH PROGRAM MANUALsubs

- Page 110 and 111: 11001 MARCOR OSH PROGRAM MANUALb. T

- Page 112 and 113: 11005 MARCOR OSH PROGRAM MANUALthe

- Page 114 and 115: MARCOR OSH PROGRAM MANUALFIGUREPAGE

- Page 116 and 117: 12000 MARCOR OSH PROGRAM MANUAL(1)

- Page 118 and 119: 12002 MARCOR OSH PROGRAM MANUAL1. C

- Page 120 and 121: 12003 MARCOR OSH PROGRAM MANUALc. L

- Page 122 and 123: 12005 MARCOR OSH PROGRAM MANUALthe

- Page 124 and 125: 12008 MARCOR OSH PROGRAM MANUAL1200

- Page 126 and 127: 12013 MARCOR OSH PROGRAM MANUALa. A

- Page 128 and 129: MARCOR OSH PROGRAM MANUALFigure 12-

- Page 130 and 131: MARCOR OSH PROGRAM MANUALSAMPLE LOC

- Page 133 and 134: MARCOR OSH PROGRAM MANUALCHAPTER 13

- Page 135 and 136: MARCOR OSH PROGRAM MANUAL 130042. P

- Page 137 and 138: MARCOR OSH PROGRAM MANUAL 13006b. 1

- Page 139 and 140: MARCOR OSH PROGRAM MANUAL 130074. T

- Page 141 and 142: MARCOR OSH PROGRAM MANUAL 13008quar

- Page 143 and 144: MARCOR OSH PROGRAM MANUAL 13008g. P

- Page 145 and 146: MARCOR OSH PROGRAM MANUAL 13008h. C

- Page 147 and 148: MARCOR OSH PROGRAM MANUAL 1300815.

- Page 150 and 151:

MARCOR OSH PROGRAM MANUALCHAPTER 14

- Page 152 and 153:

MARCOR OSH PROGRAM MANUAL 14002inst

- Page 154 and 155:

MARCOR OSH PROGRAM MANUAL 14002(2)

- Page 156 and 157:

MARCOR OSH PROGRAM MANUAL 14002rest

- Page 158 and 159:

MARCOR OSH PROGRAM MANUAL 14003resc

- Page 160 and 161:

MARCOR OSH PROGRAM MANUAL 14004c. C

- Page 162 and 163:

MARCOR OSH PROGRAM MANUAL 14008requ

- Page 164 and 165:

MARCOR OSH PROGRAM MANUALFigure 14-

- Page 167 and 168:

MARCOR OSH PROGRAM MANUALCHAPTER 15

- Page 169 and 170:

MARCOR OSH PROGRAM MANUAL 15004Cont

- Page 171 and 172:

MARCOR OSH PROGRAM MANUAL 15004Tabl

- Page 173 and 174:

MARCOR OSH PROGRAM MANUAL 15005b. C

- Page 175 and 176:

MARCOR OSH PROGRAM MANUAL 15006(4)

- Page 177 and 178:

MARCOR OSH PROGRAM MANUAL 15007Fiel

- Page 179 and 180:

MARCOR OSH PROGRAM MANUALFFigure 15

- Page 181 and 182:

MARCOR OSH PROGRAM MANUALAsbestos T

- Page 183 and 184:

MARCOR OSH PROGRAM MANUALAsbestos T

- Page 186 and 187:

MARCOR OSH PROGRAM MANUALCHAPTER 16

- Page 188 and 189:

MARCOR OSH PROGRAM MANUAL 160032. A

- Page 190 and 191:

MARCOR OSH PROGRAM MANUAL 16004c. I

- Page 192 and 193:

MARCOR OSH PROGRAM MANUAL 16008g. I

- Page 194:

MARCOR OSH PROGRAM MANUALCHAPTER 17

- Page 197 and 198:

17001 MARCOR OSH PROGRAM MANUALThes

- Page 199 and 200:

17004 MARCOR OSH PROGRAM MANUAL1700

- Page 201 and 202:

17006 MARCOR OSH PROGRAM MANUALb. C

- Page 203 and 204:

17008 MARCOR OSH PROGRAM MANUALc. L

- Page 205 and 206:

17008 MARCOR OSH PROGRAM MANUAL4. L

- Page 207 and 208:

17008 MARCOR OSH PROGRAM MANUAL6. M

- Page 209:

MARCOR OSH PROGRAM MANUALCHAPTER 18

- Page 212 and 213:

18002 MARCOR OSH PROGRAM MANUALa. C

- Page 214 and 215:

18002 MARCOR OSH PROGRAM MANUALbeen

- Page 216 and 217:

18003 MARCOR OSH PROGRAM MANUALe. W

- Page 218:

MARCOR OSH PROGRAM MANUALCHAPTER 19

- Page 221 and 222:

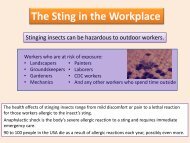

19000 MARCOR OSH PROGRAM MANUALmay

- Page 223 and 224:

19002 MARCOR OSH PROGRAM MANUAL2. T

- Page 225 and 226:

19002 MARCOR OSH PROGRAM MANUAL8. T

- Page 227 and 228:

19003 MARCOR OSH PROGRAM MANUAL3. H

- Page 229:

MARCOR OSH PROGRAM MANUALCHAPTER 20

- Page 232 and 233:

20001 MARCOR OSH PROGRAM MANUAL2. S

- Page 234 and 235:

20004 MARCOR OSH PROGRAM MANUAL2000

- Page 236 and 237:

MARCOR OSH PROGRAM MANUALAPPENDIX A

- Page 238 and 239:

MARCOR OSH PROGRAM MANUAL33. DoDDIR

- Page 240 and 241:

MARCOR OSH PROGRAM MANUAL64. NIOSH

- Page 242 and 243:

MARCOR OSH PROGRAM MANUALAPPENDIX B

- Page 244 and 245:

MARCOR OSH PROGRAM MANUALa. A flash

- Page 246 and 247:

MARCOR OSH PROGRAM MANUAL24. Parent

- Page 248:

MARCOR OSH PROGRAM MANUALnerves, jo