- Page 1 and 2:

The Proceedings of the 10 th Intern

- Page 3 and 4:

Install Adobe Reader 8 or 9 (http:/

- Page 5 and 6:

Content: POSTERS: BRAIN: CELL: EVAL

- Page 7 and 8:

Modeling of blood flow through a fl

- Page 9 and 10:

The mesh generation of the model wa

- Page 11 and 12:

Figure6 . The stroke volume data fo

- Page 13 and 14:

Digital Subtraction Phonocardiograp

- Page 15 and 16:

mobile cart for easy recording in c

- Page 17 and 18:

Figure 7. This image shows PCG samp

- Page 19 and 20:

Our approach is an improvement in t

- Page 21 and 22:

one cements as well as its behaviou

- Page 23 and 24:

Typical dimensions of lumbar verteb

- Page 25 and 26:

attributed to the change of stiffne

- Page 27 and 28:

lifestyle and obesity. In that cont

- Page 29 and 30:

T was the temperature in Kelvin and

- Page 31 and 32:

sustained tensile strains stimulate

- Page 33 and 34:

An approach aiming at determining a

- Page 35 and 36:

failure load. 2.4 Simulation of reh

- Page 37 and 38:

REFERENCES 1. Vunjak-Novakovic G, A

- Page 39 and 40:

3. FIF-BAL BIOREACTOR The FIF devic

- Page 41 and 42:

value of p nearest to dqc=0 we cont

- Page 43 and 44:

(Wanless, 1999). This low value cou

- Page 45 and 46:

3. MATERIALS AND METHODS A CAD mode

- Page 47 and 48:

did not allow gap closure. Maximum

- Page 49 and 50:

hand, if the IFM is too large, remo

- Page 51 and 52:

2. INTRODUCTION Intervertebral disc

- Page 53 and 54:

Figure 3. T1 signal enhancement in

- Page 55 and 56:

1. ABSTRACT TIP CELLS AT THE TOP: M

- Page 57 and 58:

Fig. 1. Schematic overview of the m

- Page 59 and 60:

Fig. 3. Image of the amount of VEGF

- Page 61 and 62:

THE COMPUTATIONAL MODEL OF DENTAL I

- Page 63 and 64:

processing application STL Model Cr

- Page 65 and 66:

For the implant/bone interaction as

- Page 67 and 68:

ABSTRACT THE IMPACT OF SELECTION BI

- Page 69 and 70:

Figure 1: flow chart showing the op

- Page 71 and 72:

Figure 2: Time course of cytosolic

- Page 73 and 74:

CONSTITUTIVE MODELLING OF THE ANNUL

- Page 75 and 76:

it is well known the non-linear nat

- Page 77 and 78:

Therefore, we have decided to carry

- Page 79 and 80:

EXTRACTION OF PHALANGEAL JOINT PARA

- Page 81 and 82:

column vectors of P. Denoting the v

- Page 83 and 84:

End i joint angles and length offse

- Page 85 and 86:

Validation of Strain Mapping for th

- Page 87 and 88:

allows the calculation of strain ma

- Page 89 and 90:

RMS error was 0.054 and the strains

- Page 91 and 92:

AN APPROACH FOR THE REDUCTION OF TH

- Page 93 and 94:

The relation between the time-deriv

- Page 95 and 96:

Error in position [mm] Error in pos

- Page 97 and 98:

ANALYSIS OF THE INTRAINDIVIDUAL DIF

- Page 99 and 100:

Fig.1: Frontal view on all subchond

- Page 101 and 102:

[6] M. Bozkurt, B. B. Kentel, G. Ya

- Page 103 and 104:

on the actual necessary time needed

- Page 105 and 106:

Illustration 2: The initially spher

- Page 107 and 108:

cell if it is hardly able to deform

- Page 109 and 110:

fit with a reference anatomy in min

- Page 111 and 112:

show that patellar mal-positioning

- Page 113 and 114:

Experimental and numerical analysis

- Page 115 and 116:

stenosis in both simulations and ex

- Page 117 and 118:

stented case, corresponding to the

- Page 119 and 120:

EVALUATION OF DIFFERENT LOADING CON

- Page 121 and 122:

were modeled with identical geometr

- Page 123 and 124:

each simulation and the position of

- Page 125 and 126:

FINITE ELEMENT MODEL ANALYSIS OF HU

- Page 127 and 128:

Figure 1: Maximal principal strains

- Page 129 and 130:

Method for classification of porcin

- Page 131 and 132:

3.3 Identification of Paths Accordi

- Page 133 and 134:

Table. 1. Descriptive Patterns used

- Page 135 and 136:

CHARACTERIZING THE MECHANICAL MICRO

- Page 137 and 138:

3.1.3 Cell proliferation It is assu

- Page 139 and 140:

Stress [Pa] 4 3 2 1 0 Mean stress A

- Page 141 and 142:

REFERENCES [1] A.M. Bratt-Leal, R.L

- Page 143 and 144:

y exposure to interstitial fluid sh

- Page 145 and 146:

according to (Eq. 2), nor averaged

- Page 147 and 148:

emoved the oscillations partially a

- Page 149 and 150:

static load and a dynamic load. A s

- Page 151 and 152:

positive effect of the number of ac

- Page 153 and 154:

pathways and their interactions tha

- Page 155 and 156:

applications, the need for accuracy

- Page 157 and 158:

avoid violating the initial geometr

- Page 159 and 160:

6. CONCLUSION The examples of appli

- Page 161 and 162:

Fig. 1 Semicircular canal structure

- Page 163 and 164:

4. RESULT Fig. 6 FSI model of semic

- Page 165 and 166:

6. ACKNOWLEDGEMENT This research wa

- Page 167 and 168:

ods to the biocompatible plastic po

- Page 169 and 170:

Table 1: Analysis conditions Static

- Page 171 and 172:

[3] Brantigan, J. W., Steffee, A. D

- Page 173 and 174:

femoral head fracture, the femoral

- Page 175 and 176:

Fig 3. Schematic drawing of the ste

- Page 177 and 178:

6. CONCLUSION Fig 7. Analysis resul

- Page 179 and 180:

and angular rates were registered b

- Page 181 and 182:

former, there were assumed the foll

- Page 183 and 184:

delivered dynamic support, which pr

- Page 185 and 186:

insertion of provisional restoratio

- Page 187 and 188:

Figure 4: Implant displacements obt

- Page 189:

5. DISCUSSION AND CONCLUSION Initia

- Page 192 and 193:

at which microdamage originates. Fo

- Page 194 and 195:

4. RESULTS The load response varied

- Page 196 and 197:

current study to explore the effect

- Page 198 and 199:

implant correctly from the finite e

- Page 200 and 201:

(a) (b) (c) (d) (e) Figure 3. The s

- Page 202 and 203:

(a) (b) Figure 6. The meshed model

- Page 204 and 205:

(a) (b) Figure 9. Cumulative probab

- Page 206 and 207:

NUMERICAL EVALUATION AND MEDICAL CO

- Page 208 and 209:

compared by overlaying the real dat

- Page 210 and 211:

four sample patient data, outcomes

- Page 212 and 213:

A POROELASTIC APPROACH FOR AN OPEN

- Page 214 and 215:

where indexes U, P refer to the unk

- Page 216 and 217:

RESULTS As a preliminary test, a 0.

- Page 218 and 219:

BIOMECHANICAL BEHAVIOR OF CANCELLOU

- Page 220 and 221:

cement acts perfectly, therefore it

- Page 222 and 223:

cancellous bone of natural joints a

- Page 224 and 225:

COMPUTATIONAL MODELING OF TANGLED A

- Page 226 and 227:

The centers of the simulated cells

- Page 228 and 229:

untangled, the local fiber displace

- Page 230 and 231:

TOWARDS A WAVELET BASED MEDICAL IMA

- Page 232 and 233:

however at each decomposition scale

- Page 234 and 235:

the MATLAB software (for the Modifi

- Page 236 and 237:

A FLUID STRUCTURE INTERACTION MODEL

- Page 238 and 239:

hyperelastic based on available exp

- Page 240 and 241:

t [ms] 30 70 160 220 270 Pressure [

- Page 242 and 243:

MECHANICAL BAHAVIOR OF DIFFERENT NI

- Page 244 and 245:

parameters necessaries to use this

- Page 246 and 247:

F1 and Mtwo were directly related t

- Page 248 and 249:

MECHANICAL EFFECT ON METABOLIC TRAN

- Page 250 and 251:

an initial nil lactate concentratio

- Page 252 and 253:

present study, such values were phe

- Page 254 and 255:

EVALUATION OF FEMORAL COMPONENT MIC

- Page 256 and 257:

TS implants employed a “hybrid”

- Page 258 and 259:

5. DISCUSSION i ii Figure 2: Compar

- Page 260 and 261:

THE MECHANICAL ENVIRONMENT IN THE D

- Page 262 and 263:

instead the femur was supported by

- Page 264 and 265:

It must be noted however, that in t

- Page 266 and 267:

1. ABSTRACT MODELING OF ARTICULAR C

- Page 268 and 269:

exp 1 1 2 1 where and are i

- Page 270 and 271:

Implant Fig.2. Axisymmetric represe

- Page 272 and 273:

A MULTI-SCALE ANISOTROPIC CONSTITUT

- Page 274 and 275:

3.2 Decoupled invariant formulation

- Page 276 and 277:

Fig. 1. Experimental data from unia

- Page 278 and 279:

VALIDATION AND CALIBRATION PROCESSE

- Page 280 and 281:

Figure 1: A three-step process simu

- Page 282 and 283:

The validation process employed on

- Page 284 and 285:

FLUID-STRUCTURE INTERACTION ANALYSI

- Page 286 and 287:

The coupled SQA model and the conve

- Page 288 and 289:

Point P7, located at the toe of the

- Page 290 and 291:

THE INFLUENCE OF UNCERTAIN ANATOMIC

- Page 292 and 293:

Figure 3 exemplifies for intradisca

- Page 294 and 295:

8. CONCLUSIONS Unsurprisingly, the

- Page 296 and 297:

COMPARISON OF DIFFERENT LOADING CON

- Page 298 and 299:

Figure 1 Finite element model of th

- Page 300 and 301:

6 CONCLUSION It is a feasible way t

- Page 302 and 303:

FROM CELL CONTRACTILITY TO CURVATUR

- Page 304 and 305:

4. MODEL When cells adhere on a sub

- Page 306 and 307:

organisation. Understanding the pri

- Page 308 and 309:

PREOPERATIVE PLANNING SUPPORT SYSTE

- Page 310 and 311:

[9]. Stenosis of 25, 45, 65 and 85

- Page 312 and 313:

Fig. 1:Dependent and independent va

- Page 314 and 315:

1. ABSTRACT Local strain measuremen

- Page 316 and 317:

around 100µm (halfway through the

- Page 318 and 319:

sampling points at different cross

- Page 320 and 321:

CLASSIFICATION OF PHYSICAL ACTIVITY

- Page 322 and 323:

induces a vertical alignment of the

- Page 324 and 325:

accelerations combination). However

- Page 326 and 327:

line under translation. Information

- Page 328 and 329:

In this study, we apply a meshless

- Page 330 and 331:

used the PAC constitutive constants

- Page 332 and 333:

1006031) is gratefully acknowledged

- Page 334 and 335:

improvements were seen in both grou

- Page 336 and 337:

Pre-augmentation Position 1, V=3mL

- Page 338 and 339:

5. ACKNOWLEDGEMENTS Funding for thi

- Page 340 and 341:

the hemodynamics in cerebral aneury

- Page 342 and 343:

4. RESULTS AND DISCUSSION In order

- Page 344 and 345:

processing methods need to be devel

- Page 346 and 347:

3. METHODS 3.1 Experimental Method

- Page 348 and 349:

Figure 2 - Micrographs for tensile

- Page 350 and 351:

analysis of the tissue mechanics. B

- Page 352 and 353:

3. METHODS 3.1 Specimen Preparation

- Page 354 and 355:

of five points across the mid mid-c

- Page 356 and 357:

equired to replicate the deformatio

- Page 358 and 359:

pre-load within the plate (compress

- Page 360 and 361:

4. RESULTS The load-deformation beh

- Page 362 and 363:

fracture fixation. Medical Engineer

- Page 364 and 365:

model. It approximates knee kinemat

- Page 366 and 367:

computational cost remains moderate

- Page 368 and 369:

Concerning the optimization procedu

- Page 370 and 371:

aesthetic recovery. However, in som

- Page 372 and 373:

atio experimented by both wounds is

- Page 374 and 375:

VARIATION OF MICRO-ARCHITECTURE AND

- Page 376 and 377:

osteoporotic (OP). The sample volum

- Page 378 and 379:

Figure 4: Mean error in orthotropy

- Page 380 and 381:

INVESTIGATION OF CORTICAL SHELL STR

- Page 382 and 383:

When creating the degenerated FE mo

- Page 384 and 385:

Figure 4. Degeneration sensitivity

- Page 386 and 387:

METHODS TO ACCELERATE FINITE ELEMEN

- Page 388 and 389:

the “joint” constraints configu

- Page 390 and 391:

Figure 4: Absolute prediction error

- Page 392 and 393:

EFFECT OF POST TREATMENT FOR MULTIP

- Page 394 and 395:

Fig.2 Inlet velocity profile indica

- Page 396 and 397: 4.3 WSS results Figure 8 shows the

- Page 398 and 399: approximated by the so-called Ritz

- Page 400 and 401: Figure 2: Viscohyperelastic cube: (

- Page 402 and 403: There is no optimal density-elastic

- Page 404 and 405: Fig. 2 Cut view of FE-model. Shown

- Page 406 and 407: 5. Weis JA, Miga MI, Granero-Moltó

- Page 408 and 409: 3. SYSTEM DESIGN Sheep eyes, as the

- Page 410 and 411: which provides natural tactile feed

- Page 412 and 413: 113:341-342 20. Henderson B. A., Gr

- Page 414 and 415: health area. According to estimates

- Page 416 and 417: Table 1. RMS Value based on subject

- Page 418 and 419: 6. REFERENCES 1. http://www.disable

- Page 420 and 421: ehavior [5]. From the viewpoint of

- Page 422 and 423: Fig. 1 Average Male and Female's L4

- Page 424 and 425: 4. Deyo, R.A., and Weinstein, J. N.

- Page 426 and 427: geometry of the cell and ECM degrad

- Page 428 and 429: Shown in Fig. 2(b) is a plot of the

- Page 430 and 431: 6. REFERENCES 1. Dubin-Thaler B.J.,

- Page 432 and 433: We implemented our individual-based

- Page 434 and 435: 3.3.1 Centers of mass Table 1: Base

- Page 436 and 437: average coordination num ber averag

- Page 438 and 439: BIOMECHANICAL ANALYSIS OF THE MUSCU

- Page 440 and 441: of the ligament strain; a linear re

- Page 442 and 443: lengthening, respectively, if compa

- Page 444 and 445: THE EFFECT OF HIGH TIBIAL OSTEOTOMY

- Page 448 and 449: Table II: Peak medial and lateral f

- Page 450 and 451: INVESTIGATING CHANGES IN JOINT LOAD

- Page 452 and 453: 4. RESULTS Table 1 shows the mean m

- Page 454 and 455: Fig.5 displays the OKS and KOS pre

- Page 456 and 457: Dynamic Touch of Effective Golf Swi

- Page 458 and 459: properties of a golf club and hand

- Page 460 and 461: perturbation in e3 whereas player B

- Page 462 and 463: 1. Kim, W., Response to letter to t

- Page 464 and 465: configuration.[4] have explained ho

- Page 466 and 467: compartments as well as a single mu

- Page 468 and 469: 5. Shabana, A.A., Dynamics of multi

- Page 470 and 471: Five healthy volunteers (age: 38.3

- Page 472 and 473: internal lumbar spinal shape was de

- Page 480 and 481: Airflow Simulation of Nasal Cavity

- Page 482: temperature [5], and Wbl is the wat

- Page 485 and 486: Figure 8. Figure 8(a) illustrates t

- Page 487 and 488: Finite element models of the hip ca

- Page 489 and 490: 3.2 Finite Element Analysis Followi

- Page 491 and 492: 5. DISCUSSION Previous DEA implemen

- Page 493 and 494: STATISTICAL SHAPE MODELING OF CAM-T

- Page 495 and 496: Thirty-three control femurs (25 mal

- Page 497 and 498:

asymptomatic subjects 7,9 . The Hot

- Page 499 and 500:

6. REFERENCES 1. Ganz, R., Parvizi,

- Page 501 and 502:

NUMERICAL IDENTIFICATION OF THE PER

- Page 503 and 504:

2. METHOD AND NUMERICAL MODEL. 2.1

- Page 505 and 506:

1 u dV V u. (Eq. 2) V The permeab

- Page 507 and 508:

1. ABSTRACT PASSIVE AND ACTIVE MUSC

- Page 509 and 510:

presented in figure 2 the simulatio

- Page 511 and 512:

Indenter Stroke [mm] Muscle Force [

- Page 513 and 514:

Objectives Long bone failure charac

- Page 515 and 516:

the specimens in three point bendin

- Page 517 and 518:

developing a subject-specific finit

- Page 519 and 520:

Models used in the past, mostly bas

- Page 521 and 522:

In this work it is presented the de

- Page 523 and 524:

Average Table 1.- Walk average test

- Page 525 and 526:

angles for the step of 2.28° and 8

- Page 527 and 528:

insufficiency syndrome (TIS), defin

- Page 529 and 530:

a) b) c) Fig. 5 - Contact interface

- Page 531 and 532:

EOS. Among these options, VEPTR has

- Page 533 and 534:

dissection occurs when blood intrud

- Page 535 and 536:

mean value of 0.0310 m s -1 . The o

- Page 537 and 538:

progression. It can in turn contrib

- Page 539 and 540:

dependent data. They conclude that

- Page 541 and 542:

found that it is extremely difficul

- Page 543 and 544:

endering loop is started and the ra

- Page 545 and 546:

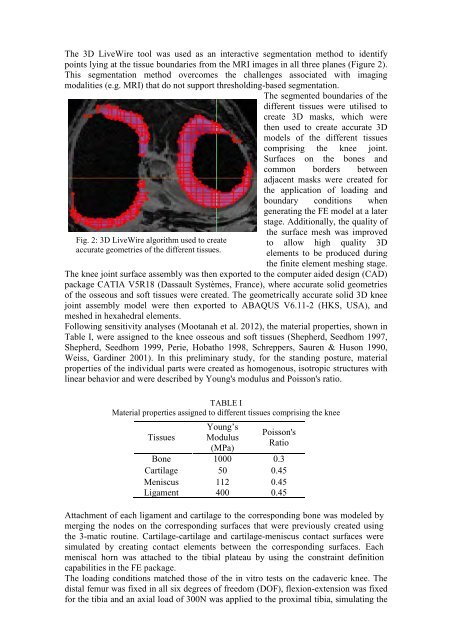

3.1 Imaging protocol of the knee A

- Page 547 and 548:

Fig. 3: Pressure distribution in th

- Page 549 and 550:

7. REFERENCES 1. Masouros, S.D., Bu

- Page 551 and 552:

and estimate in vivo tissue strains

- Page 553 and 554:

tendon has a larger moment arm abou

- Page 555 and 556:

Song, H. M., Smith, R. L., Longaker

- Page 557 and 558:

Fig. 1. Single line transducer resu

- Page 559 and 560:

Let P INT be the data set of the lo

- Page 561 and 562:

could quantify the initial structur

- Page 563 and 564:

expansion of a stent, a metallic sc

- Page 565 and 566:

immediately after stent expansion a

- Page 567 and 568:

6. ACKNOWLEDGMENT This research is

- Page 569 and 570:

Deformation of the arterial surface

- Page 571 and 572:

separate study to be described in a

- Page 573 and 574:

3. Timmins, L.H., Miller M.W. Clubb

- Page 575 and 576:

migrate in a unique fashion to the

- Page 577 and 578:

Fig. 1: Domain and schematic repres

- Page 579 and 580:

Furthermore, the values are spread

- Page 581 and 582:

this study, our goal is to establis

- Page 583 and 584:

Figure 3. Relative length change in

- Page 585 and 586:

5. Erdemir A, Sibole S. Open Knee:

- Page 587 and 588:

lateralis (inferior and superior) f

- Page 589 and 590:

during mouth closing and chewing. O

- Page 591 and 592:

BIOMECHANICAL MODELING OF THE HUMAN

- Page 593 and 594:

appropriates mechanical properties

- Page 595 and 596:

Fig. 4: Correlation of the location

- Page 597 and 598:

1. ABSTRACT COMPUTER AIDED TUMOR RE

- Page 599 and 600:

B. Cutting planes The surgeon defin

- Page 601 and 602:

4.RESULTS To test the developed sys

- Page 603 and 604:

FROM PATIENT-SPECIFIC DATA TO MULTI

- Page 605 and 606:

catheterization mean measurements (

- Page 607 and 608:

the different virtual surgical desi

- Page 609 and 610:

1. ABSTRACT DIGITAL ULTRASOUND DESP

- Page 611 and 612:

2.2 Filtering Based Wavelet 2.2.1 C

- Page 613 and 614:

Table 1: quantitative criteria used

- Page 615 and 616:

Mural Thrombosis in a Two-Level Com

- Page 617 and 618:

But, the soft repulsive force can n

- Page 619 and 620:

Ratio of adhered PLT a simplificati

- Page 621 and 622:

DEGRADATION OF MAGNESIUM ALLOY STEN

- Page 623 and 624:

study and the parameter setting can

- Page 625 and 626:

Fig. 5. Damage evolution of the thr

- Page 627 and 628:

NUMERICAL SIMULATIONS OF FATIGUE FO

- Page 629 and 630:

Figure 1. Scheme of the two approac

- Page 631 and 632:

Figure 3. On the left, alternating

- Page 633 and 634:

INVESTIGATION OF HEAD-NECK KINEMATI

- Page 635 and 636:

complexity of the vertebrae and sku

- Page 637 and 638:

nearly no tension occurred for the

- Page 639 and 640:

9. Ito S, Ivancic PC, Panjabi MM, C

- Page 641 and 642:

[Ntsinjana et al., 2011], commonly

- Page 643 and 644:

impedances were maintained within p

- Page 645 and 646:

6. Pennati G., Corsini C., Cosentin

- Page 647 and 648:

analyse the effect that different a

- Page 649 and 650:

attached cases this value was highe

- Page 651 and 652:

References 1. Nordin M and Frankel

- Page 653:

therapy to achieve the desired medi

- Page 657 and 658:

iomechanical response of the leg to

- Page 659 and 660:

algorithm has to be integrated into

- Page 661 and 662:

to a modification in the tooth disp

- Page 663 and 664:

5. CONCLUSIONS 5.1 Geometry and per

- Page 665 and 666:

present work is to show the ability

- Page 667 and 668:

[6,7]. In order to reproduce numeri

- Page 669 and 670:

5. DISCUSSION, CONCLUSIONS AND PERS

- Page 671 and 672:

3.1 Generation of the vertebral sur

- Page 673 and 674:

3.4 Modeling of the facet joints Th

- Page 675 and 676:

The column diagramm of Fig.8 shows

- Page 677 and 678:

tool to evaluate the drug distribut

- Page 679 and 680:

Figure 3: The mean value of the dos

- Page 681 and 682:

INFLUENCE OF KYPHOSIS ON SPINAL LOA

- Page 683 and 684:

(a) (b) (c) Fig. 1. The three repre

- Page 685 and 686:

etween T6 and T9 with a higher degr

- Page 687 and 688:

A COMPARISON BETWEEN STANDARD AND D

- Page 689 and 690:

the SB with a 2.5 mm balloon; ii) o

- Page 691 and 692:

A TAWSS [Pa] B OSI [Pa] C 0 0.25 0.

- Page 693 and 694:

ABSTRACT CONSTITUTIVE MODELLING OF

- Page 695 and 696:

20% compression strains were impose

- Page 697 and 698:

4. DISCUSSION The limited number of

- Page 699 and 700:

AN ALGORITHM FOR MODELING THE FIBRE

- Page 701 and 702:

1 - Compute the centre of the botto

- Page 703 and 704:

(a) (b) Figure 2. Load-displacement

- Page 705 and 706:

A bio-mechanics based methodology t

- Page 707 and 708:

to a particular body part based on

- Page 709 and 710:

Injury Cost (USD) Million 0.7 0.6 0

- Page 711 and 712:

A SENSITIVITY ANALYSIS OF ADAPTIVE

- Page 713 and 714:

elationships can be found that rela

- Page 715 and 716:

Fig. 2: Percentage of bone volume w

- Page 717 and 718:

APPLICATION OF REACTION-DIFFUSION W

- Page 719 and 720:

AIRFLOW VENTILATION THROUGH HUMAN M

- Page 721 and 722:

solve all the governing equations.

- Page 723 and 724:

Fig. 4 Streamlines through the osti

- Page 725 and 726:

MOLECULAR DYNAMICS SIMULATIONS FOR

- Page 727 and 728:

COARSE-GRAINED MOLECULAR DYNAMICS S

- Page 729 and 730:

DESIGN AND STRUCTURAL EVALUATION OF

- Page 731 and 732:

Figure 2 shows the optimal unit-cel

- Page 733 and 734:

ENUM (MPa) 100 90 80 70 60 50 40 30

- Page 735 and 736:

vivo menisco-tibial kinematics duri

- Page 737 and 738:

Loading the fully extended knee wit

- Page 739 and 740:

is also subject to variation due to

- Page 741 and 742:

environment in comparison to fixed

- Page 743 and 744:

4. RESULTS AND DISCUSSION Convergen

- Page 745 and 746:

Because of the orthotropic assumpti

- Page 747 and 748:

3D RECONSTRUCTION OF STENTED PORCIN

- Page 749 and 750:

Fluid model. The final configuratio

- Page 751 and 752:

Table 1: Computed slice measurement

- Page 753 and 754:

ANALYSIS OF THE EFFECT OF CONSIDERI

- Page 755 and 756:

For all these models, C1 = µ/2, µ

- Page 757 and 758:

the difference in percentage betwee

- Page 759 and 760:

A COMPUTATIONAL METHOD TO ESTIMATE

- Page 761 and 762:

C10, C01 and d were taken from [10]

- Page 763 and 764:

4. RESULTS Fig. 2 shows the results

- Page 765 and 766:

COMPUTATIONAL AND EXPERIMENTAL MODE

- Page 767 and 768:

data using commercial software (Mim

- Page 769 and 770:

vitro (40 vs 34%), at the expense o

- Page 771 and 772:

FINITE ELEMENT ANALYSES OF IN VIVO

- Page 773 and 774:

The non-linear behaviour of the art

- Page 775 and 776:

Figure 6. Constant-life diagram for

- Page 777 and 778:

Optimal acceleration adjustment to

- Page 779 and 780:

, , , ,

- Page 781 and 782:

The vertical force bump observed du

- Page 783 and 784:

NEURAL NETWORK-BASED PREDICTION OF

- Page 785 and 786:

3. MATERIAL AND METHODS 3.1 Experim

- Page 787 and 788:

from subjects S1, S2, S3, S5, and S

- Page 789 and 790:

APPLICATION OF A MODIFIED ELASTIC F

- Page 791 and 792:

h and h being the thickness of the

- Page 793 and 794:

0.3 were used for the flat surface

- Page 795 and 796:

simulations of the mechanical respo

- Page 797 and 798:

50000 images have been acquired. Th

- Page 799 and 800:

Fig.1 Modules of the proposed capsu

- Page 801 and 802:

5. CONCLUSION This paper describes

- Page 803 and 804:

dependent on the implementation of

- Page 805 and 806:

joint computer model was driven wit

- Page 807 and 808:

otation. The AP laxity test showed

- Page 809 and 810:

A COMPUTATIONAL MODEL OF THE GROWTH

- Page 811 and 812:

where n p is the number of prolifer

- Page 813 and 814:

Hypertrophic columnar cartilage 0.2

- Page 815 and 816:

SIMULATION OF DAILY LIVING MOVEMENT

- Page 817 and 818:

otations were kept at zero, since t

- Page 819 and 820:

cavity (van der Helm, 1994). Howeve

- Page 821 and 822:

Solving Overconstrained Kinematic i

- Page 823 and 824:

3.3. Muscles Muscles are modelled a

- Page 825 and 826:

5. DISCUSSION A musculoskeletal num

- Page 827 and 828:

EFFECT OF OSCILATORY FLOW ON MORPHO

- Page 829 and 830:

dimensionless frequency . With the

- Page 831 and 832:

Wntsignaling, J Clin Invest., 2006,

- Page 833 and 834:

Maximization (EM) algorithm witch e

- Page 835 and 836:

4. RESULTS: n 1 2 x f ( x ; )

- Page 837 and 838:

5. CONCLUSION In this work, a semi-

- Page 839 and 840:

allow cell construct image inspecti

- Page 841 and 842:

formula can be written as a linear

- Page 843 and 844:

( ) (4) Poisson‟s ratio was assum

- Page 845 and 846:

a) b) c) d) Figure 7 Validation: a)

- Page 847 and 848:

DEVELOPMENT OF A NEW COMPUTATIONAL

- Page 849 and 850:

The ScanIP wizard creates the new i

- Page 851 and 852:

Fig. 5: Computer experiments: poste

- Page 853 and 854:

A BIOMECHANICAL CONCEPT FOR CONSTRU

- Page 855 and 856:

Figure 3. Construction of the radia

- Page 857 and 858:

6. REFERENCES 1. Lees, S., A study

- Page 859 and 860:

from cadaver surgeries were recreat

- Page 861 and 862:

mean resection parameters and the p

- Page 863 and 864:

5. DISCUSSION This study proposes a

- Page 865 and 866:

simulations are evaluated by quanti

- Page 867 and 868:

improvement of the shoulder prosthe

- Page 869 and 870:

13. Coley B., Jolles B. M., Farron

- Page 871 and 872:

simulations. Implicit in this setup

- Page 873 and 874:

assigned zero fluid pressure bounda

- Page 875 and 876:

the efficacy of predicting cellular

- Page 877 and 878:

Another important function of the l

- Page 879 and 880:

The insert (Fig. 3) is the part aga

- Page 881 and 882:

changes due to the testing conditio

- Page 883 and 884:

3. IN VIVO MEASURED LOAD COMPONENTS

- Page 885 and 886:

anthropometric data - a data set fo

- Page 887 and 888:

COMPUTATIONAL MODELING OF HIGHLY PO

- Page 889 and 890:

objects smaller than one tenth of a

- Page 891 and 892:

as 221.5 MPa. This value is more th

- Page 893 and 894:

Macrostress and Macrostrain Finite

- Page 895 and 896:

3.2. Extraction of individual artic

- Page 897 and 898:

Unique strain patterns were observe

- Page 899 and 900:

poroviscoelastic simulation of the

- Page 901 and 902:

anchorage of the cartilage into a p

- Page 903 and 904:

load of 0.5 N) resulted in a 55 kPa

- Page 905 and 906:

properties as well as protect the h

- Page 907 and 908:

Dynamic cell seeding combines two c

- Page 909 and 910:

order (PB). The particles adhered (

- Page 911 and 912:

2. D. Wendt, A. Marsano, M. Jakob,

- Page 913 and 914:

2. Only a few high-level clinical s

- Page 915 and 916:

A quasi-static analysis was perform

- Page 917 and 918:

e increased by using stiffer or tig

- Page 919 and 920:

Despite the importance of taking th

- Page 921 and 922:

Table 2: Score chart presented to t

- Page 923 and 924:

We conclude that the model develope

- Page 925 and 926:

presented system - parallelization

- Page 927 and 928:

image is projected to the subsequen

- Page 929 and 930:

6. CONCLUSIONS The presented in the

- Page 931 and 932:

first simulation uses data provided

- Page 933 and 934:

Table 1: Models used in this study.

- Page 935 and 936:

direction at knee extension, placin

- Page 937 and 938:

3. METHODS 3.1. Model of heat trans

- Page 939 and 940:

condition before and after heating.

- Page 941 and 942:

during daily activities reported in

- Page 943 and 944:

samples of brain tissue were extrac

- Page 945 and 946:

5. DETERMINING MECHANICAL PROPERTIE

- Page 947 and 948:

2001, Vol. 38 (4), 335-345. 8. Vela

- Page 949 and 950:

chamber [4]. After obtaining the va

- Page 951 and 952:

4. RESULTS 4.2 Surface and solid me

- Page 953:

7. ACKNOWLEDGMENTS Financial fundin

- Page 956 and 957:

affect crack penetration into osteo

- Page 958 and 959:

Therefore, in order to examine the

- Page 960 and 961:

3. Mischinski, S., Ural, A., 2011,

- Page 962 and 963:

esearchers. The power of a finite-e

- Page 964 and 965:

figure 2, we can determine the node

- Page 966 and 967:

architecture, Muscle & Nerve, 2004,

- Page 968 and 969:

ensure good short-term and long-ter

- Page 970 and 971:

Table I - Micromotion results at th

- Page 972 and 973:

COMBINED BONE-IMPLANT FIXATION: A P

- Page 974 and 975:

FRICTIONAL PROPERTIES OF OSTEOARTHR

- Page 976 and 977:

With the following boundary conditi

- Page 978 and 979:

pressures higher than normal contac

- Page 980 and 981:

1. ABSTRACT DYNAMIC PRESSURE RESPON

- Page 982 and 983:

quasi-static solution, and both pos

- Page 984 and 985:

(excluding the cadaveric validation

- Page 987 and 988:

AN ANALYTICAL MODEL TO INVESTIGATE

- Page 989 and 990:

K sh = 2. 3E sh 2 ( ) 2 1 2 1−ν

- Page 991 and 992:

Fig. 7 modeling the oblique impact

- Page 993 and 994:

A NON-LINEAR BIPHASIC MODEL FOR THE

- Page 995 and 996:

system, it is convenient to write t

- Page 997 and 998:

only with very small damping parame

- Page 999 and 1000:

A PARAMETERIZED FE MODEL FOR SIMULA

- Page 1001 and 1002:

the study of Polikeit et al. [10].

- Page 1003 and 1004:

There are obvious limitations to ou

- Page 1005 and 1006:

Abnormal stresses are often cited a

- Page 1007 and 1008:

4. RESULTS The methods used to meas

- Page 1009 and 1010:

that muscle imbalance associated wi

- Page 1011 and 1012:

BIOCHEMICAL MODEL TO PREDICT THE ON

- Page 1013 and 1014:

3.1 Model description The regulator

- Page 1015 and 1016:

[3] Shier D., 2001, Hole’s Human

- Page 1017 and 1018:

Biomechanics of Human Gluteal Tissu

- Page 1019 and 1020:

information. Based on the indentati

- Page 1021 and 1022:

t 1 ⎧⎪ ⎫ 2 2 ⎪ ττττ ( t

- Page 1023 and 1024:

REFERENCES 1. Gefen A., Gefen N., L

- Page 1025 and 1026:

analysis of the large-scale human m

- Page 1027 and 1028:

λ σ = σ (8) act isom f f 0 ⋅

- Page 1029 and 1030:

In the absence of membranes, the mu

- Page 1031 and 1032:

predicted. This is possible for mod

- Page 1033 and 1034:

-7.2 mN. The average value of the m

- Page 1035:

efore the joint moment reaches zero