Manual - 8500A Series Peak Power Meter - Giga-tronics

Manual - 8500A Series Peak Power Meter - Giga-tronics

Manual - 8500A Series Peak Power Meter - Giga-tronics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

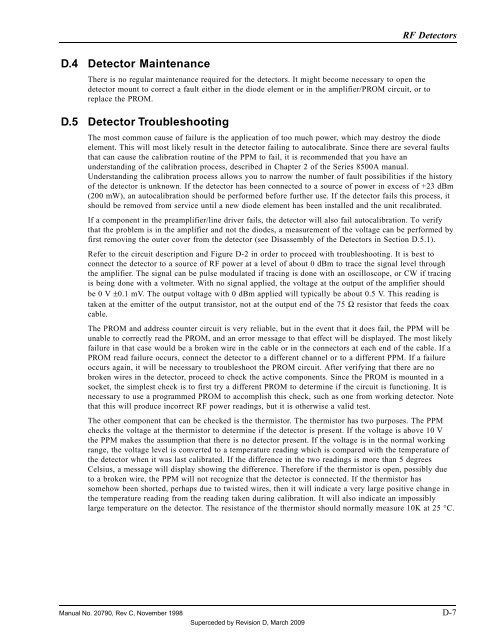

RF Detectors<br />

D.4 Detector Maintenance<br />

There is no regular maintenance required for the detectors. It might become necessary to open the<br />

detector mount to correct a fault either in the diode element or in the amplifier/PROM circuit, or to<br />

replace the PROM.<br />

D.5 Detector Troubleshooting<br />

The most common cause of failure is the application of too much power, which may destroy the diode<br />

element. This will most likely result in the detector failing to autocalibrate. Since there are several faults<br />

that can cause the calibration routine of the PPM to fail, it is recommended that you have an<br />

understanding of the calibration process, described in Chapter 2 of the <strong>Series</strong> <strong>8500A</strong> manual.<br />

Understanding the calibration process allows you to narrow the number of fault possibilities if the history<br />

of the detector is unknown. If the detector has been connected to a source of power in excess of +23 dBm<br />

(200 mW), an autocalibration should be performed before further use. If the detector fails this process, it<br />

should be removed from service until a new diode element has been installed and the unit recalibrated.<br />

If a component in the preamplifier/line driver fails, the detector will also fail autocalibration. To verify<br />

that the problem is in the amplifier and not the diodes, a measurement of the voltage can be performed by<br />

first removing the outer cover from the detector (see Disassembly of the Detectors in Section D.5.1).<br />

Refer to the circuit description and Figure D-2 in order to proceed with troubleshooting. It is best to<br />

connect the detector to a source of RF power at a level of about 0 dBm to trace the signal level through<br />

the amplifier. The signal can be pulse modulated if tracing is done with an oscilloscope, or CW if tracing<br />

is being done with a voltmeter. With no signal applied, the voltage at the output of the amplifier should<br />

be 0 V ±0.1 mV. The output voltage with 0 dBm applied will typically be about 0.5 V. This reading is<br />

taken at the emitter of the output transistor, not at the output end of the 75 Ω resistor that feeds the coax<br />

cable.<br />

The PROM and address counter circuit is very reliable, but in the event that it does fail, the PPM will be<br />

unable to correctly read the PROM, and an error message to that effect will be displayed. The most likely<br />

failure in that case would be a broken wire in the cable or in the connectors at each end of the cable. If a<br />

PROM read failure occurs, connect the detector to a different channel or to a different PPM. If a failure<br />

occurs again, it will be necessary to troubleshoot the PROM circuit. After verifying that there are no<br />

broken wires in the detector, proceed to check the active components. Since the PROM is mounted in a<br />

socket, the simplest check is to first try a different PROM to determine if the circuit is functioning. It is<br />

necessary to use a programmed PROM to accomplish this check, such as one from working detector. Note<br />

that this will produce incorrect RF power readings, but it is otherwise a valid test.<br />

The other component that can be checked is the thermistor. The thermistor has two purposes. The PPM<br />

checks the voltage at the thermistor to determine if the detector is present. If the voltage is above 10 V<br />

the PPM makes the assumption that there is no detector present. If the voltage is in the normal working<br />

range, the voltage level is converted to a temperature reading which is compared with the temperature of<br />

the detector when it was last calibrated. If the difference in the two readings is more than 5 degrees<br />

Celsius, a message will display showing the difference. Therefore if the thermistor is open, possibly due<br />

to a broken wire, the PPM will not recognize that the detector is connected. If the thermistor has<br />

somehow been shorted, perhaps due to twisted wires, then it will indicate a very large positive change in<br />

the temperature reading from the reading taken during calibration. It will also indicate an impossibly<br />

large temperature on the detector. The resistance of the thermistor should normally measure 10K at 25 °C.<br />

<strong>Manual</strong> No. 20790, Rev C, November 1998 D-7<br />

Superceded by Revision D, March 2009