Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

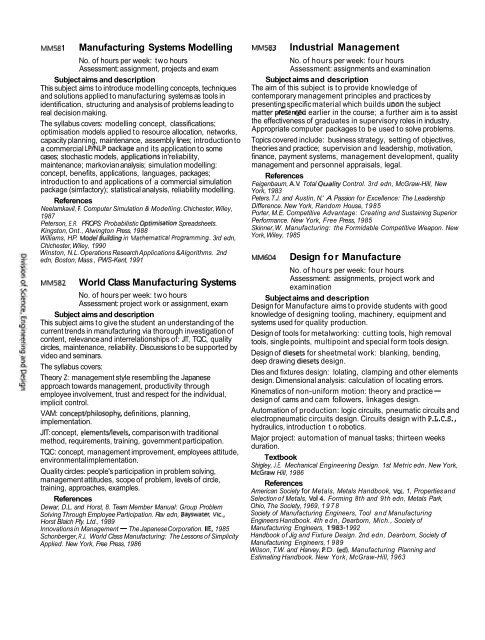

~ ~ 5 8 Manufacturing 1<br />

Systems Modelling<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: assignment, projects and exam<br />

Subject aims and description<br />

This subject aims to introduce modelling concepts, techniques<br />

and solutions applied to manufacturing systems as tools in<br />

identification, structuring and analysis <strong>of</strong> problems leading to<br />

real decision making.<br />

The syllabus covers: modelling concept, classifications;<br />

optimisation models applied to resource allocation, networks,<br />

capacity planning, maintenance, assembly lines; introduction to<br />

a commercial LP/NLP ~ackaae and its application to some<br />

cases; stochastic models, applications in'reliability,<br />

maintenance; markovian analysis; simulation modelling:<br />

concept, benefits, applications, languages, packages;<br />

introduction to and applications <strong>of</strong> a commercial simulation<br />

package (simfactory); statistical analysis, reliability modelling.<br />

References<br />

Neelamkavil, F. Computer Simulation & Modelling. Chichester, Wiley,<br />

1987<br />

Peterson, E.R. PROPS: Probabilistic Optimisation Spreadsheets.<br />

Kingston, Ont., Alwington Press, 1988<br />

Williams, H.P. ModelBuilding in MathematicalProgramming. 3rd edn,<br />

Chichester, Wiley, 1990<br />

Winston, N.L. Operations Research Applications &Algorithms. 2nd<br />

edn, Boston, Mass., PWS-Kent, 1991<br />

~ ~ 5 8World 2 Class Manufacturing Systems<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: project work or assignment, exam<br />

Subject aims and description<br />

This subject aims to give the student an understanding <strong>of</strong> the<br />

current trends in manufacturing via thorough investigation <strong>of</strong><br />

content, relevance and interrelationships <strong>of</strong>: JIT, TQC, quality<br />

circles, maintenance, reliability. Discussions to be supported by<br />

video and seminars.<br />

The syllabus covers:<br />

Theory Z: management style resembling the Japanese<br />

approach towards management, productivity through<br />

employee involvement, trust and respect for the individual,<br />

implicit control.<br />

VAM: concept/philosophy, definitions, planning,<br />

implementation.<br />

JIT: concept, elements/levels, comparison with traditional<br />

method, requirements, training, government participation.<br />

TQC: concept, management improvement, employees attitude,<br />

environmental implementation.<br />

Quality circles: people's participation in problem solving,<br />

management attitudes, scope <strong>of</strong> problem, levels <strong>of</strong> circle,<br />

training, approaches, examples.<br />

References<br />

Dewar, D.L. and Horst, 8. Team Member Manual: Group Problem<br />

Solving Through Employee Participation. Rev edn, Bayswater, Vic.,<br />

Horst Blaich Pty. Ltd., 1989<br />

Innovations in Management - The Japanese Corporation. IIE, 1985<br />

Schonberger, R.J. World Class Manufacturing: The Lessons <strong>of</strong> Simplicity<br />

Applied. New York, Free Press, 1986<br />

~ ~ 5 8 Industrial 3 Management<br />

No. <strong>of</strong> hours per week: four hours<br />

Assessment: assignments and examination<br />

Subject aims and description<br />

The aim <strong>of</strong> this subject is to provide knowledge <strong>of</strong><br />

contemporary management principles and practices by<br />

presentinq specific material which builds won the subiect<br />

hatter earlier in the course; a further aim iito assist<br />

the effectiveness <strong>of</strong> graduates in supervisory roles in industry.<br />

Appropriate computer packages to be used to solve problems.<br />

Topics covered include: business strategy, setting <strong>of</strong> objectives,<br />

theories and practice; supervision and leadership, motivation,<br />

finance, payment systems, management development, quality<br />

management and personnel appraisals, legal.<br />

References<br />

Feigenbaum, A.V. Total Quality Control. 3rd edn, McGraw-Hill, New<br />

York, 1983<br />

Peters. T.J. and Austin, N.' A Passion for Excellence: The Leadership<br />

Difference. New York, Random House, 1985<br />

Porter, M.E. Competitive Advantage: Creating and Sustaining Superior<br />

Performance. New York, Free Press, 1985<br />

Skinner, W. Manufacturing: the Formidable Competitive Weapon. New<br />

York, Wiley, 1985<br />

~ ~ 6 0Design 4 for Manufacture<br />

No. <strong>of</strong> hours per week: four hours<br />

Assessment: assignments, project work and<br />

examination<br />

Subject aims and description<br />

Design for Manufacture aims to provide students with good<br />

knowledge <strong>of</strong> designing tooling, machinery, equipment and<br />

systems used for quality production.<br />

Design <strong>of</strong> tools for metalworking: cutting tools, high removal<br />

tools, single points, multipoint and special form tools design.<br />

Design <strong>of</strong> diesets for sheetmetal work: blanking, bending,<br />

deep drawing diesets design.<br />

Dies and fixtures design: lolating, clamping and other elements<br />

design. Dimensional analysis: calculation <strong>of</strong> locating errors.<br />

Kinematics <strong>of</strong> non-uniform motion: theory and practice -<br />

design <strong>of</strong> cams and cam followers, linkages design.<br />

Automation <strong>of</strong> production: logic circuits, pneumatic circuits and<br />

electropneumatic circuits design. Circuits design with P.L.C.S.,<br />

hydraulics, introduction t o robotics.<br />

Major project: automation <strong>of</strong> manual tasks; thirteen weeks<br />

duration.<br />

Textbook<br />

Shigley, J.E. Mechanical Engineering Design. 1st Metric edn, New York,<br />

McGraw Hill, 1986<br />

References<br />

American Society for Metals, Metals Handbook, Vol. 1, Properties and<br />

Selection <strong>of</strong> Metals, Vo14. Forming 8th and 9th edn, Metals Park,<br />

Ohio, The Society, 1969, 1978<br />

Society <strong>of</strong> Manufacturing Engineers, Tool and Manufacturing<br />

Engineers Handbook. 4th edn, Dearborn, Mich., Society <strong>of</strong><br />

Manufacturing Engineers, 1983-1 992<br />

Handbook <strong>of</strong> Jig and Fixture Design. 2nd edn, Dearborn, Society <strong>of</strong><br />

Manufacturing Engineers, 1 989<br />

Wilson, T.W. and Harvey, P.D. (ed). Manufacturing Planning and<br />

Estimating Handbook. New York, McGraw-Hill, 1963