Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

forming; general requirements, mechanical tests, tensile test,<br />

analysis <strong>of</strong> stress-strain curves and parameters, r and n<br />

values, tests to simulate processes, stretch forming tests,<br />

deep-drawing tests, bending tests, forming-limit diagrams,<br />

applications. Function and terminology for die components;<br />

blanking dies, commercially available die sets, punches and<br />

accessories.<br />

Numerical control; introduction to NC machine tools,<br />

comparison with conventional, hardware configurations,<br />

s<strong>of</strong>tware implementation, control systems, machine control<br />

unit, feedback, sensitivity. NC system components;<br />

comparison <strong>of</strong> actuation systems, electric, hydraulic,<br />

pneumatic. Design considerations for NC machine tools;<br />

design differences between conventional and NC machines,<br />

mechanical design considerations, control system design<br />

considerations. System inputloutput; types <strong>of</strong> input media,<br />

symbolic codes, tape input format, communication with<br />

MCU. NC programming; programming methods, computer<br />

assisted NC programming [processors, post; processors], part<br />

programming languages - Am. Computer Numerical<br />

Control (CNC), Direct Numerical Control (DNC); comparison,<br />

management implications.<br />

Plastics and rubbers; overview <strong>of</strong> processes. Melt forming,<br />

rheology, mathematical analysis <strong>of</strong> pseudoplastic, dilatent,<br />

newtonian flow, time dependant flow, thixotropy, viscosity,<br />

tractional viscosity. Extrusion defects; causes and prevention.<br />

Extrusion die design. Single and multiple screw extrusion;<br />

hardware and product characteristics, Injection moulding;<br />

mould design, basics <strong>of</strong> the moldflow philosophy, cooling<br />

systems. Therm<strong>of</strong>orming die design. Elastomers; C black,<br />

other additives, compounding. Compression and injection<br />

moulding.<br />

Textbooks<br />

Crawford, R.J. Plastic; Engineering. 2nd ed, Oxford: Pergamon Press,<br />

1987<br />

Groover, M.P. Automation, Production Systems and Computer<br />

Integrated Manufacturing. 2nd ed, Englewood Cliffs, N.J.: Prentice<br />

Hall, 1987<br />

References<br />

Harris, J.N. Mechanical Working <strong>of</strong> Metals. Oxford: Pergamon, 1983<br />

Kalpakjian, S. Manufacturing Processes for Engineering Materials. 2nd<br />

ed, Reading, Mass.: Addison-Wesley, 1991<br />

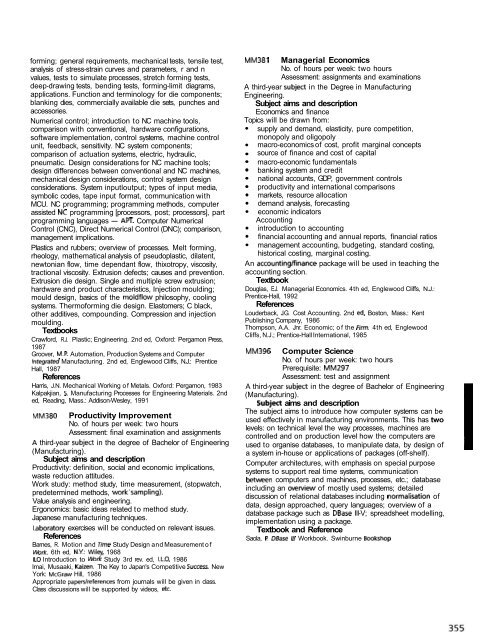

~ ~ 3 8Productivity 0 Improvement<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: final examination and assignments<br />

A third-year subjed in the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

(Manufacturing).<br />

Subject aims and description<br />

Productivity: definition, social and economic implications,<br />

waste reduction attitudes.<br />

Work study: method study, time measurement, (stopwatch,<br />

predetermined methods, work.sampling).<br />

Value analysis and engineering.<br />

Ergonomics: basic ideas related to method study.<br />

Japanese manufacturing techniques.<br />

laboratory exercises will be conducted on relevant issues.<br />

References<br />

Barnes, R. Motion and Time Study Design and Measurement <strong>of</strong><br />

Mrk. 6th ed, N.Y.: Wiley, 1968<br />

110 Introduction to Wrk Study 3rd rev. ed, I.L.0, 1986<br />

Imai, Musaaki, Kaizen. The Key to Japan's Competitive Succezs New<br />

York: McGraw Hill, 1986<br />

Appropriate paperslreferences from journals will be given in class.<br />

Class discussions will be supported by videos, etc.<br />

MM381 Managerial Economics<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: assignments and examinations<br />

A third-year subject in the Degree in Manufacturing<br />

Engineering.<br />

Subject aims and description<br />

Economics and finance<br />

Topics will be drawn from:<br />

supply and demand, elasticity, pure competition,<br />

monopoly and oligopoly<br />

macro-economics <strong>of</strong> cost, pr<strong>of</strong>it marginal concepts<br />

source <strong>of</strong> finance and cost <strong>of</strong> capital<br />

macro-economic fundamentals<br />

banking system and credit<br />

national accounts, GDP, government controls<br />

productivity and international comparisons<br />

markets, resource allocation<br />

demand analysis, forecasting<br />

economic indicators<br />

Accounting<br />

introduction to accounting<br />

financial accounting and annual reports, financial ratios<br />

management accounting, budgeting, standard costing,<br />

historical costing, marginal costing.<br />

An accountinglfinance package will be used in teaching the<br />

accounting section.<br />

Textbook<br />

Douglas, E.J. Managerial Economics. 4th ed, Englewood Cliffs, N.J.:<br />

Prentice-Hall, 1992<br />

References<br />

Louderback, J.G. Cost Accounting. 2nd ed. Boston, Mass.: Kent<br />

Publishing Company, 1986<br />

Thompson, A.A. Jnr. Economic; <strong>of</strong> the Fim. 4th ed, Englewood<br />

Cliffs, N.J.; Prentice-Hall International, 1985<br />

MM396 Computer Science<br />

No. <strong>of</strong> hours per week: two hours<br />

Prerequisite: MM297<br />

Assessment: test and assignment<br />

A third-year subjed in the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

(Manufacturing).<br />

Subject aims and description<br />

The subject aims to introduce how computer systems can be<br />

used effectively in manufacturing environments. This has two<br />

levels: on technical level the way processes, machines are<br />

controlled and on production level how the computers are<br />

used to organise databases, to manipulate data, by design <strong>of</strong><br />

a system in-house or applications <strong>of</strong> packages (<strong>of</strong>f-shelf).<br />

Computer architectures, with emphasis on special purpose<br />

systems to support real time systems, communication<br />

between computers and machines, processes, etc.; database<br />

including an overview <strong>of</strong> mostly used systems; detailed<br />

discussion <strong>of</strong> relational databases including normalisation <strong>of</strong><br />

data, design approached, query languages; overview <strong>of</strong> a<br />

database package such as DBase Ill-V; spreadsheet modelling,<br />

implementation using a package.<br />

Textbook and Reference<br />

Saola, P. DBase IN Workbook. <strong>Swinburne</strong> Bookshop