Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

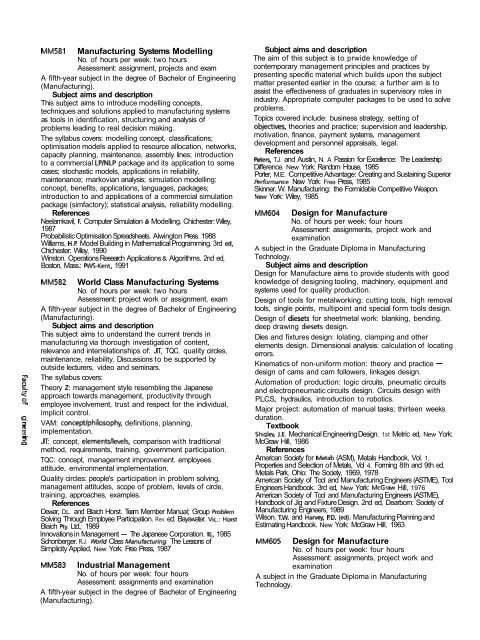

MM581 Manufacturing Systems Modelling<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: assignment, projects and exam<br />

A fifth-year subject in the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

(Manufacturing).<br />

Subject aims and description<br />

This subject aims to introduce modelling concepts,<br />

techniques and solutions applied to manufacturing systems<br />

as tools in identification, structuring and analysis <strong>of</strong><br />

problems leading to real decision making.<br />

The syllabus covers: modelling concept, classifications;<br />

optimisation models applied to resource allocation, networks,<br />

capacity planning, maintenance, assembly lines; introduction<br />

to a commercial LPINLP package and its application to some<br />

cases; stochastic models, applications in reliability,<br />

maintenance; markovian analysis; simulation modelling:<br />

concept, benefits, applications, languages, packages;<br />

introduction to and applications <strong>of</strong> a commercial simulation<br />

package (simfactory); statistical analysis, reliability modelling.<br />

References<br />

Neelamkavil, F. Computer Simulation & Modelling. Chichester: Wiley,<br />

1987<br />

Probabilistic Optimisation Spreadsheets. Alwington Press. 1988<br />

Williams, H.R Model Building in Mathematical Programming. 3rd ed,<br />

Chichester: Wiley, 1990<br />

Winston. Operations Research Applications & Algorithms. 2nd ed,<br />

Boston, Mass.: PWS-Kent. 1991<br />

MM582 World Class Manufacturing Systems<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: project work or assignment, exam<br />

A fifth-year subject in the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

(Manufacturing).<br />

Subject aims and description<br />

This subject aims to understand the current trends in<br />

manufacturing via thorough investigation <strong>of</strong> content,<br />

relevance and interrelationships <strong>of</strong>: JIT, TQC, quality circles,<br />

maintenance, reliability. Discussions to be supported by<br />

outside lecturers, video and seminars.<br />

The syllabus covers:<br />

n<br />

r Theory Z: management style resembling the Japanese<br />

approach towards management, productivity through<br />

2, employee involvement, trust and respect for the individual,<br />

.- implicit control.<br />

'Y.<br />

VAM: conceptlphilosophy, definitions, planning,<br />

m<br />

q -. implementation.<br />

JIT: concept, elementsllevels, comparison with traditional<br />

method, requirements, training, government participation.<br />

TQC: concept, management improvement. employees<br />

attitude, environmental implementation.<br />

Quality circles: people's participation in problem solving,<br />

management attitudes, scope <strong>of</strong> problem, levels <strong>of</strong> circle,<br />

training, approaches, examples.<br />

References<br />

Dewar, D.L. and Blaich Horst. Team Member Manual; Group Problem<br />

Solving Through Employee Participation. Rev ed. Bayswater. Vic.: Horst<br />

Blaich Pty Ltd., 1989<br />

Innovations in Management - The Japanese Corporation. IIE, 1985<br />

Schonberger. R.J. Wrld Class Manufacturing. The Lessons <strong>of</strong><br />

Simplicity Applied, New York: Free Press, 1987<br />

MM583 Industrial Management<br />

No. <strong>of</strong> hours per week: four hours<br />

Assessment: assignments and examination<br />

A fifth-year subject in the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

(Manufacturing).<br />

Subject aims and description<br />

The aim <strong>of</strong> this subject is to prwide knowledge <strong>of</strong><br />

contemporary management principles and practices by<br />

presenting specific material which builds upon the subject<br />

matter presented earlier in the course; a further aim is to<br />

assist the effectiveness <strong>of</strong> graduates in supervisory roles in<br />

industry. Appropriate computer packages to be used to solve<br />

problems.<br />

Topics covered include: business strategy, setting <strong>of</strong><br />

objectiws, theories and practice; supervision and leadership,<br />

motivation, finance, payment systems, management<br />

development and personnel appraisals, legal.<br />

References<br />

Men. T.J. and Austin, N. A Passion for Excellence: The Leadership<br />

Difference. New York: Random House, 1985<br />

Porter, M.E. Competitive Advantage: Creating and Sustaining Superior<br />

krformance. New York: Free Press, 1985<br />

Skinner. W. Manufacturing: the Formidable Competitive Weapon.<br />

New York: Wiley, 1985<br />

MM604 Design for Manufacture<br />

No. <strong>of</strong> hours per week: four hours<br />

Assessment: assignments, project work and<br />

examination<br />

A subject in the Graduate Diploma in Manufacturing<br />

<strong>Technology</strong>.<br />

Subject aims and description<br />

Design for Manufacture aims to provide students with good<br />

knowledge <strong>of</strong> designing tooling, machinery, equipment and<br />

systems used for quality production.<br />

Design <strong>of</strong> tools for metalworking: cutting tools, high removal<br />

tools, single points, multipoint and special form tools design.<br />

Design <strong>of</strong> diesets for sheetmetal work: blanking, bending.<br />

deep drawing diesets design.<br />

Dies and fixtures design: lolating, clamping and other<br />

elements design. Dimensional analysis: calculation <strong>of</strong> locating<br />

errors.<br />

Kinematics <strong>of</strong> non-uniform motion: theory and practice -<br />

design <strong>of</strong> cams and cam followers, linkages design.<br />

Automation <strong>of</strong> production: logic circuits, pneumatic circuits<br />

and electropneumatic circuits design. Circuits design with<br />

P.L.C.S., hydraulics, introduction to robotics.<br />

Major project: automation <strong>of</strong> manual tasks; thirteen weeks<br />

duration.<br />

Textbook<br />

Shigley, J.E. Mechanical Engineering Design. 1st Metric ed, New York:<br />

McGraw Hill, 1986<br />

References<br />

American Society for Metab (ASM), Metals Handbook, Vol. 1,<br />

Properties and Selection <strong>of</strong> Metals, Vol 4. Forming 8th and 9th ed.<br />

Metals Park, Ohio: The Society, 1969, 1978<br />

American Society <strong>of</strong> Tool and Manufacturing Engineers (ASTME), Tool<br />

Engineers Handbook. 3rd ed, New York: McGraw Hill, 1976<br />

American Society <strong>of</strong> Tool and Manufacturing Engineers (ASTME),<br />

Handbook <strong>of</strong> Jig and Fixture Design. 2nd ed, Dearborn: Society <strong>of</strong><br />

Manufacturing Engineers, 1989<br />

Wilson. T.W. and Hatvey, ED. (4). Manufacturing Planning and<br />

Estimating Handbook. New York: McGraw Hill, 1963<br />

MM605 Design for Manufacture<br />

No. <strong>of</strong> hours per week: four hours<br />

Assessment: assignments, project work and<br />

examination<br />

A subject in the Graduate Diploma in Manufacturing<br />

<strong>Technology</strong>.