Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

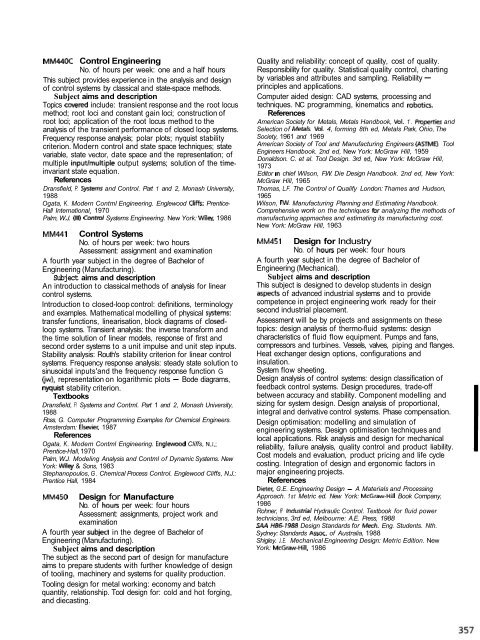

MM440C Control Engineering<br />

No. <strong>of</strong> hours per week: one and a half hours<br />

This subject provides experience in the analysis and design<br />

<strong>of</strong> control systems by classical and state-space methods.<br />

Subject aims and description<br />

Topics cwred include: transient response and the root locus<br />

method; root loci and constant gain loci; construction <strong>of</strong><br />

root loci; application <strong>of</strong> the root locus method to the<br />

analysis <strong>of</strong> the transient performance <strong>of</strong> closed loop systems.<br />

Frequency response analysis; polar plots; nyquist stability<br />

criterion. Modern control and state space techniques; state<br />

variable, state vector, date space and the representation; <strong>of</strong><br />

multiple inputlmuttiple output systems; solution <strong>of</strong> the timeinvariant<br />

state equation.<br />

References<br />

Dransfield, P. Systems and Control. Part 1 and 2, Monash <strong>University</strong>,<br />

1988<br />

Ogata, K. Modern Contml Engineering. Englewood Cliffs: Prentice-<br />

Hall International. 1970<br />

Palm, W.J. (110 ~ontml Systems Engineering. New York: Wiley, 1986<br />

MM441 Control Systems<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: assignment and examination<br />

A fourth year subject in the degree <strong>of</strong> Bachelor <strong>of</strong><br />

Engineering (Manufacturing).<br />

Subject aims and description<br />

An introduction to classical methods <strong>of</strong> analysis for linear<br />

control systems.<br />

Introduction to closed-loop control: definitions, terminology<br />

and examples. Mathematical modelling <strong>of</strong> physical syjtems:<br />

transfer functions, linearisation, block diagrams <strong>of</strong> closedloop<br />

systems. Transient analysis: the inverse transform and<br />

the time solution <strong>of</strong> linear models, response <strong>of</strong> first and<br />

second order systems to a unit impulse and unit step inputs.<br />

Stability analysis: Routh's stability criterion for linear control<br />

systems. Frequency response analysis: steady state solution to<br />

sinusoidal inputs'and the frequency response function G<br />

(jw), representation on logarithmic plots - Bode diagrams,<br />

nyquist stability criterion.<br />

Textbooks<br />

Dransfield, F! Systems and Contml. Part 1 and 2, Monash <strong>University</strong>,<br />

1988<br />

Ross, G. Computer Programming Examples for Chemical Engineers.<br />

Amsterdam: Elsevier, 1987<br />

References<br />

Ogata, K. Modem Contml Engineering. Englewood Cliffs, N.1.:<br />

Prentice-Hall, 1970<br />

Palm, W.J. Modeling Analysis and Contml <strong>of</strong> Dynamic Systems. New<br />

York: Wiley & Sons, 1983<br />

Stephanopoulos, G. Chemical Process Control. Englewood Cliffs, N.J.:<br />

Prentice Hall, 1984<br />

MM450 Design for Manufacture<br />

No. <strong>of</strong> houn per week: four hours<br />

Assessment: assignments, project work and<br />

examination<br />

A fourth year subject in the degree <strong>of</strong> Bachelor <strong>of</strong><br />

Engineering (Manufacturing).<br />

Subject aims and description<br />

The subject as the second part <strong>of</strong> design for manufacture<br />

aims to prepare students with further knowledge <strong>of</strong> design<br />

<strong>of</strong> tooling, machinery and systems for quality production.<br />

Tooling design for metal working: economy and batch<br />

quantity, relationship. Tool design for: cold and hot forging,<br />

and diecasting.<br />

Quality and reliability: concept <strong>of</strong> quality, cost <strong>of</strong> quality.<br />

Responsibility for quality. Statistical quality control, charting<br />

by variables and attributes and sampling. Reliability -<br />

principles and applications.<br />

Computer aided design: CAD systems, processing and<br />

techniques. NC programming, kinematics and robotics.<br />

References<br />

American Society for Metals, Metals Handbook, Vol. 1. Pmprties and<br />

Selection <strong>of</strong> Metab Vol. 4, forming 8th ed, Metals Park, Ohio, The<br />

Society, 1961 and 1969<br />

American Society <strong>of</strong> Tool and Manufacturing Engineers (ASTME). Tool<br />

Engineers Handbook. 2nd ed, New York: McGraw Hill, 1959<br />

Donaldson. C. et al. Tool Design. 3rd ed, New York: McGraw Hill,<br />

1973<br />

Editor In chief Wilson, F.W. Die Design Handbook. 2nd ed, New York:<br />

McGraw Hill, 1965<br />

Thomas, L.F. The Control <strong>of</strong> Qualify London: Thames and Hudson,<br />

1965<br />

Wilson, F.W. Manufacturing Planning and Estimating Handbook.<br />

Comprehensive work on the techniques b r analyzing the methods <strong>of</strong><br />

manufacturing appmaches and estimating its manufacturing cost.<br />

New York: McGraw Hill, 1963<br />

MM451 Design for Industry<br />

No. <strong>of</strong> hours per week: four hours<br />

A fourth year subject in the degree <strong>of</strong> Bachelor <strong>of</strong><br />

Engineering (Mechanical).<br />

Subject aims and description<br />

This subject is designed to develop students in design<br />

aspects <strong>of</strong> advanced industrial systems and to provide<br />

competence in project engineering work ready for their<br />

second industrial placement.<br />

Assessment will be by projects and assignments on these<br />

topics: design analysis <strong>of</strong> thermo-fluid systems: design<br />

characteristics <strong>of</strong> fluid flow equipment. Pumps and fans,<br />

compressors and turbines. Vessels, valves, piping and flanges.<br />

Heat exchanger design options, configurations and<br />

insulation.<br />

System flow sheeting.<br />

Design analysis <strong>of</strong> control systems: design classification <strong>of</strong><br />

feedback control systems. Design procedures, trade-<strong>of</strong>f<br />

between accuracy and stability. Component modelling and<br />

sizing for system design. Design analysis <strong>of</strong> proportional,<br />

integral and derivative control systems. Phase compensation.<br />

Design optimisation: modelling and simulation <strong>of</strong><br />

engineering systems. Design optimisation techniques and<br />

local applications. Risk analysis and design for mechanical<br />

reliability, failure analysis, quality control and product liability.<br />

Cost models and evaluation, product pricing and life cycle<br />

costing. Integration <strong>of</strong> design and ergonomic factors in<br />

major engineering projects.<br />

References<br />

D~eter, G.E. Engineering Design - A Materials and Processing<br />

Approach. 1st Metric ed. New York: McGraw-Hill Book Company,<br />

1986<br />

Rohner, F! Industrial Hydraulic Control. Textbook for fluid power<br />

technicians, 3rd ed, Melbourne: A.E. Press, 1988<br />

MA HBb1988 Design Standards for Mech. Eng. Students. Nth.<br />

Sydney: Standards Assoc. <strong>of</strong> Australia, 1988<br />

Shigley. J.E. Mechanical Engineering Design: Metric Edition. New<br />

York: McGraw-Hill. 1986