Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

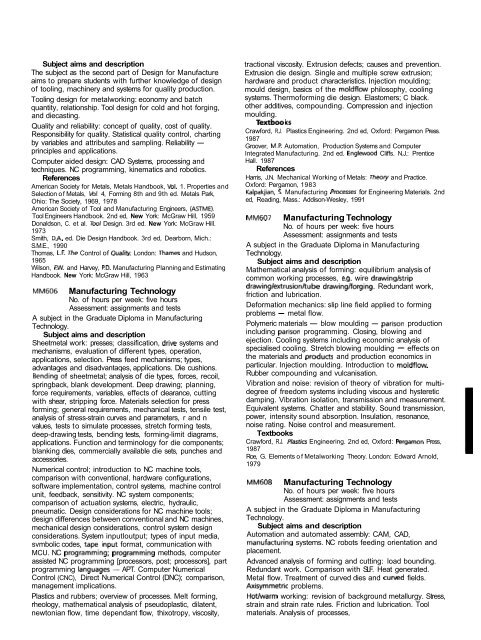

Subject aims and description<br />

The subject as the second part <strong>of</strong> Design for Manufacture<br />

aims to prepare students with further knowledge <strong>of</strong> design<br />

<strong>of</strong> tooling, machinery and systems for quality production.<br />

Tooling design for metalworking: economy and batch<br />

quantity, relationship. Tool design for cold and hot forging,<br />

and diecasting.<br />

Quality and reliability: concept <strong>of</strong> quality, cost <strong>of</strong> quality.<br />

Responsibility for quality. Statistical quality control, charting<br />

by variables and attributes and sampling. Reliability -<br />

principles and applications.<br />

Computer aided design: CAD Systems, processing and<br />

techniques. NC programming, kinematics and robotics.<br />

References<br />

American Society for Metals, Metals Handbook, Vol. 1. Properties and<br />

Selection <strong>of</strong> Metals, Lbl. 4, Forming 8th and 9th ed. Metals Park,<br />

Ohio: The Society, 1969, 1978<br />

American Society <strong>of</strong> Tool and Manufacturing Engineers, (ASTME).<br />

Tool Engineers Handbook. 2nd ed, New York: McGraw Hill, 1959<br />

Donaldson, C. et al. Tool Design. 3rd ed. New York: McGraw Hill.<br />

1973<br />

Smith, D.A. ed. Die Design Handbook. 3rd ed, Dearborn, Mich.:<br />

S.M.E., 1990<br />

Thomas, L.' The Control <strong>of</strong> Qualit): London: Thames and Hudson,<br />

1965<br />

Wilson, F.W. and Harvey, P.D. Manufacturing Planning and Estimating<br />

Handbook. New York: McGraw Hill, 1963<br />

MM606 Manufacturing <strong>Technology</strong><br />

No. <strong>of</strong> hours per week: five hours<br />

Assessment: assignments and tests<br />

A subject in the Graduate Diploma in Manufacturing<br />

<strong>Technology</strong>.<br />

Subject aims and description<br />

Sheetmetal work: presses; classification, drive systems and<br />

mechanisms, evaluation <strong>of</strong> different types, operation,<br />

applications, selection. Press feed mechanisms; types,<br />

advantaqes and disadvantaqes, applications. Die cushions.<br />

~endind<strong>of</strong> sheetmetal; analysis <strong>of</strong> die types, forces, recoil,<br />

springback, blank development. Deep drawing; planning,<br />

force requirements, variables, effects <strong>of</strong> clearance, cutting<br />

with shear, stripping force. Materials selection for press<br />

forming; general requirements, mechanical tests, tensile test,<br />

analysis <strong>of</strong> stress-strain curves and parameters, r and n<br />

values, tests to simulate processes, stretch forming tests,<br />

deep-drawing tests, bending tests, forming-limit diagrams,<br />

applications. Function and terminology for die components;<br />

blanking dies, commercially available die sets, punches and<br />

accessories.<br />

Numerical control; introduction to NC machine tools,<br />

comparison with conventional, hardware configurations,<br />

s<strong>of</strong>tware implementation, control systems, machine control<br />

unit, feedback, sensitivity. NC system components;<br />

comparison <strong>of</strong> actuation systems, electric, hydraulic,<br />

pneumatic. Design considerations for NC machine tools;<br />

design differences between conventional and NC machines,<br />

mechanical design considerations, control system design<br />

considerations. System inputloutput; types <strong>of</strong> input media,<br />

svmbolic codes. taDe in~ut format. communication with<br />

MCU. NC progiam;ning'; programming methods, computer<br />

assisted NC programming [processors, post; processors], part<br />

programming languages-- APT. Computer Numerical<br />

Control (CNC), Direct Numerical Control (DNC); comparison,<br />

management implications.<br />

Plastics and rubbers; overview <strong>of</strong> processes. Melt forming,<br />

rheology, mathematical analysis <strong>of</strong> pseudoplastic, dilatent,<br />

newtonian flow, time dependant flow, thixotropy, viscosity,<br />

tractional viscosity. Extrusion defects; causes and prevention.<br />

Extrusion die design. Single and multiple screw extrusion;<br />

hardware and product characteristics. Injection moulding;<br />

mould design, basics <strong>of</strong> the moldflow philosophy, cooling<br />

systems. Therm<strong>of</strong>orming die design. Elastomers; C black.<br />

other additives, compounding. Compression and injection<br />

moulding.<br />

Textboo kr<br />

Crawford, R.J. Plastics Engineering. 2nd ed, Oxford: Pergamon Press.<br />

1987<br />

Groover, M.P. Automation, Production Systems and Computer<br />

Integrated Manufacturing. 2nd ed. Englewood Cliffs. N.J.: Prentice<br />

Hall. 1987<br />

References<br />

Harris, J.N. Mechanical Working <strong>of</strong> Metals: Theory and Practice.<br />

Oxford: Pergamon, 1983<br />

Kalpakjian, S. Manufacturing Pmceses for Engineering Materials. 2nd<br />

ed, Reading, Mass.: Addison-Wesley, 1991<br />

MM607<br />

Manufacturing <strong>Technology</strong><br />

No. <strong>of</strong> hours per week: five hours<br />

Assessment: assignments and tests<br />

A subject in the Graduate Diploma in Manufacturing<br />

<strong>Technology</strong>.<br />

Subject aims and description<br />

Mathematical analysis <strong>of</strong> forming: equilibrium analysis <strong>of</strong><br />

common working processes, e.g. wire drawingistrip<br />

drawinglextrusion/tube drawingiforging. Redundant work,<br />

friction and lubrication.<br />

Deformation mechanics: slip line field applied to forming<br />

problems - metal flow.<br />

Polymeric materials - blow moulding - parison production<br />

including parison programming. Closing, blowing and<br />

ejection. Cooling systems including economic analysis <strong>of</strong><br />

specialised cooling. Stretch blowing moulding - effects on<br />

the materials and products and production economics in<br />

particular. lnjection moulding. Introduction to moldflow.<br />

Rubber compounding and vulcanisation.<br />

Vibration and noise: revision <strong>of</strong> theory <strong>of</strong> vibration for multidegree<br />

<strong>of</strong> freedom systems including viscous and hysteretic<br />

damping. Vibration isolation, transmission and measurement.<br />

Equivalent systems. Chatter and stability. Sound transmission,<br />

power, intensity sound absorption. Insulation, resonance,<br />

noise rating. Noise control and measurement.<br />

Textbooks<br />

Crawford, R.J. Plastics Engineering. 2nd ed, Oxford: Rrgarnon Press,<br />

1987<br />

Roe, G. Elements <strong>of</strong> Metalworking Theory. London: Edward Arnold,<br />

1979<br />

MM608 Manufacturing <strong>Technology</strong><br />

No. <strong>of</strong> hours per week: five hours<br />

Assessment: assignments and tests<br />

A subject in the Graduate Diploma in Manufacturing<br />

<strong>Technology</strong>.<br />

Subject aims and description<br />

Automation and automated assembly: CAM, CAD,<br />

manufaduring systems. NC robots feeding orientation and<br />

placement.<br />

Advanced analysis <strong>of</strong> forming and cutting: load bounding.<br />

Redundant work. Comparison with SLF. Heat generated.<br />

Metal flow. Treatment <strong>of</strong> curved dies and curwd fields.<br />

Axisymmetric problems.<br />

Hotharm working: revision <strong>of</strong> background metallurgy. Stress,<br />

strain and strain rate rules. Friction and lubrication. Tool<br />

materials. Analysis <strong>of</strong> processes,