Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Polymeric materials - blow moulding - parison production<br />

including parison programming. Closing, blowing and<br />

ejection. Cooling systems including economic analysis <strong>of</strong><br />

specialised cooling. Stretch blowing moulding - effects on<br />

the materials and products and production economics in<br />

particular. Injection moulding. lntroduction to moldflow.<br />

Rubber compounding and vulcanisation.<br />

Vibration and noise: revision <strong>of</strong> theoly <strong>of</strong> vibration for multidegree<br />

<strong>of</strong> freedom systems including viscous and hysteretic<br />

damping. Vibration isolation, transmission and measurement.<br />

Equivalent systems. Chatter and stability. Sound transmission,<br />

power, intensity sound absorption. Insulation, resonance,<br />

noise rating. Noise control and measurement.<br />

Textbooks<br />

Crawford, R.J. Plastics Engineering. 2nd ed, Oxford: Pergamon Press,<br />

1987<br />

Roe, G. Elements <strong>of</strong> Metalworking Theory London: Edward Arnold,<br />

1979<br />

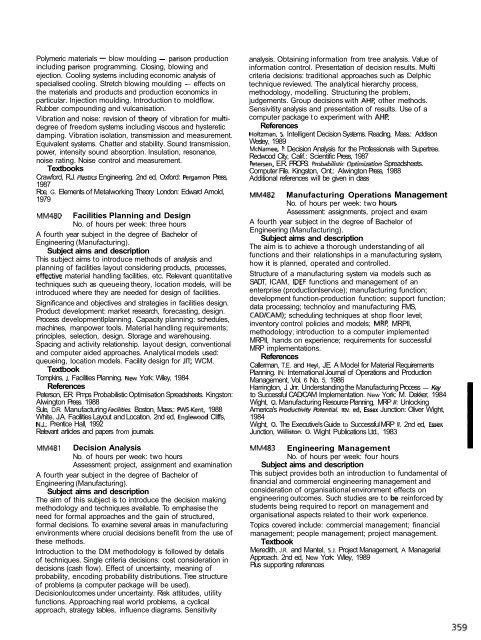

MM480 Facilities Planning and Design<br />

No. <strong>of</strong> hours per week: three hours<br />

A fourth year subject in the degree <strong>of</strong> Bachelor <strong>of</strong><br />

Engineering (Manufacturing).<br />

Subject aims and description<br />

This subject aims to introduce methods <strong>of</strong> analysis and<br />

planning <strong>of</strong> facilities layout considering products, processes,<br />

effective material handling facilities, etc. Relevant quantitative<br />

techniques such as queueing theory, location models, will be<br />

introduced where they are needed for design <strong>of</strong> facilities.<br />

Significance and objectives and strategies in facilities design.<br />

Product development: market research, forecasting, design.<br />

Process developmentlplanning. Capacity planning: schedules,<br />

machines, manpower tools. Material handling requirements;<br />

principles, selection, design. Storage and warehousing.<br />

Spacing and activity relationship. layout design, conventional<br />

and computer aided approaches. Analytical models used:<br />

queueing, location models. Facility design for JTT; WCM.<br />

Textbook<br />

Tompkins, J. Facilities Planning. NEW York: Wiley, 1984<br />

References<br />

Peterson, E.R. Pmps Probabilistic Optimisation Spreadsheets. Kingston:<br />

Alwington Press. 1988<br />

Sule, D.R. Manufacturing Facil~ties. Boston, Mass.: PWS-Kent. 1988<br />

White, J.A. Facilities Layout and Location. 2nd ed, Engl~hlood Cliffs,<br />

N.J.: Prentice Hall, 1992<br />

Relevant articles and papers from journals.<br />

MM481 Decision Analysis<br />

No. <strong>of</strong> hours per week: two hours<br />

Assessment: project, assignment and examination<br />

A fourth year subject in the degree <strong>of</strong> Bachelor <strong>of</strong><br />

Engineering (Manufacturing).<br />

Subject aims and description<br />

The aim <strong>of</strong> this subject is to introduce the decision making<br />

methodology and techniques available. To emphasise the<br />

need for formal approaches and the gain <strong>of</strong> structured,<br />

formal decisions. To examine several areas in manufacturing<br />

environments where crucial decisions benefit from the use <strong>of</strong><br />

these methods.<br />

lntroduction to the DM methodology is followed by details<br />

<strong>of</strong> techniques. Single criteria decisions: cost consideration in<br />

decisions (cash flow). Effect <strong>of</strong> uncertainty, meaning <strong>of</strong><br />

probability, encoding probability distributions. Tree structure<br />

<strong>of</strong> problems (a computer package will be used).<br />

Decisionloutcomes under uncertainty. Risk attitudes, utility<br />

functions. Approaching real world problems, a cyclical<br />

approach, strategy tables, influence diagrams. Sensitivity<br />

analysis. Obtaining information from tree analysis. Value <strong>of</strong><br />

information control. Presentation <strong>of</strong> decision results. Multi<br />

criteria decisions: traditional approaches such as Delphic<br />

technique reviewed. The analytical hierarchy process,<br />

methodology, modelling. Structuring the problem,<br />

judgements. Group decisions with AHP. other methods.<br />

Sensivitity analysis and presentation <strong>of</strong> results. Use <strong>of</strong> a<br />

computer package to experiment with AHP<br />

References<br />

Holtzman, 5. Intelligent Decision Systems. Reading, Mass.: Addison<br />

Wesley, 1989<br />

McNamee, F! Decision Analysis for the Pr<strong>of</strong>essionals with Supertree.<br />

Redwood City, Calif.: Scientific Press, 1987<br />

Petersen. E.R. PROPS: Probabilistic Optimimtion Spreadsheets.<br />

Computer File. Kingston, Ont.: Alwington Press, 1988<br />

Additional references will be given in class<br />

MM482 Manufacturing Operations Management<br />

No. <strong>of</strong> hours per week: two houn<br />

Assessment: assignments, project and exam<br />

A fourth year subject in the degree <strong>of</strong> Bachelor <strong>of</strong><br />

Engineering (Manufacturing).<br />

Subject aims and description<br />

The aim is to achieve a thorough understanding <strong>of</strong> all<br />

functions and their relationships in a manufacturing system,<br />

how it is planned, operated and controlled.<br />

Structure <strong>of</strong> a manufacturing system via models such as<br />

SADT, ICAM, IDEF functions and management <strong>of</strong> an<br />

enterprise (productionlservice); manufacturing function;<br />

development function-production function; support function;<br />

data processing; technoloy and manufacturing FMS,<br />

CADICAM); scheduling techniques at shop floor level;<br />

inventory control policies and models; MRP. MRPII,<br />

methodology; introduction to a computer implemented<br />

MRPII, hands on experience; requirements for successful<br />

MRP implementations.<br />

References<br />

Callerman, T.E. and Heyl, J.E. A Model for Material Requirements<br />

Planning. IN: International Journal <strong>of</strong> Operations and Production<br />

Management, Vol. 6 No. 5, 1986<br />

Harrington, J. Jnr. Understanding the Manufacturing Process - Key<br />

to Successful CAD/CAM Implementation. New York: M. Dekker, 1984<br />

Wight, 0. Manufacturing Resource Planning, MRP 1: Unlocking<br />

America's Pmductiviiy btential. rev. ed, Essex Junction: Oliver Wight,<br />

1984<br />

Wight, 0. The Executive's Guide to Successful MRP I1 2nd ed, Essex<br />

Junction, Williston: 0. Wight Publications Ltd., 1983<br />

MM483 Engineering Management<br />

No. <strong>of</strong> hours per week: four hours<br />

Subject aims and description<br />

This subject provides both an introduction to fundamental <strong>of</strong><br />

financial and commercial engineering management and<br />

consideration <strong>of</strong> organisational environment effects on<br />

engineering outcomes. Such studies are to be reinforced by<br />

students being required to report on management and<br />

organisational aspects related to their work experience.<br />

Topics covered include: commercial management; financial<br />

management; people management; project management.<br />

Textbook<br />

Meredith, J.R. and Mantel, S.J. Project Management, A Managerial<br />

Approach. 2nd ed, New York: Wiley, 1989<br />

Plus supporting references