Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Please note - Swinburne University of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

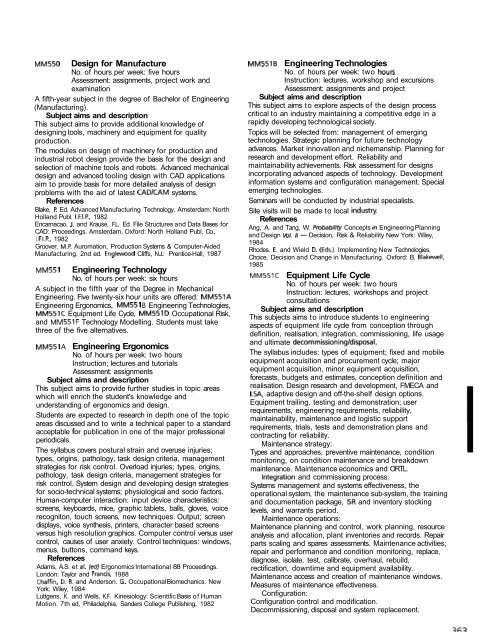

MM550<br />

Design for Manufacture<br />

No. <strong>of</strong> hours per week: five hours<br />

Assessment: assignments, project work and<br />

examination<br />

A fifth-year subject in the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

(Manufacturing).<br />

Subject aims and description<br />

This subject aims to provide additional knowledge <strong>of</strong><br />

designing tools, machinery and equipment for quality<br />

production.<br />

The modules on design <strong>of</strong> machinery for production and<br />

industrial robot design provide the basis for the design and<br />

selection <strong>of</strong> machine tools and robots. Advanced mechanical<br />

design and advanced tooling design with CAD applications<br />

aim to provide basis for more detailed analysis <strong>of</strong> design<br />

problems with the aid <strong>of</strong> latest CADICAM systems.<br />

References<br />

Blake, P. Ed. Advanced Manufacturing <strong>Technology</strong>. Amsterdam: North<br />

Holland Publ. I.F.I.P., 1982<br />

Encarnacao. 1. and Krause, F.L. Ed. File Structures and Data Bases for<br />

CAD: Proceedings. Amsterdam, Oxford: North Holland Publ. Co.,<br />

I.F.I.P., 1982<br />

Groover, M.P Auromation, Production Systems & Computer-Aided<br />

Manufacturing. 2nd ed. Englewood Cliffs, N.J.: Prentice-Hall, 1987<br />

~ ~ 5 5Engineering 1 <strong>Technology</strong><br />

No. <strong>of</strong> hours per week: six hours<br />

A subject in the fifth year <strong>of</strong> the Degree in Mechanical<br />

Engineering. Five twenty-six hour units are <strong>of</strong>fered: MM551A<br />

Engineering Ergonomics, MM551 B Engineering Technologies,<br />

MM55lC Equipment Life Cycle, MM551D Occupational Risk,<br />

and MM551F <strong>Technology</strong> Modelling. Students must take<br />

three <strong>of</strong> the five alternatives.<br />

MM551 A Engineering Ergonomics<br />

No. <strong>of</strong> hours per week: two hours<br />

Instruction; lectures and tutorials<br />

Assessment: assignments<br />

Subject aims and description<br />

This subject aims to provide further studies in topic areas<br />

which will enrich the student's knowledge and<br />

understanding <strong>of</strong> ergonomics and design.<br />

Students are expected to research in depth one <strong>of</strong> the topic<br />

areas discussed and to write a technical paper to a standard<br />

acceptable for publication in one <strong>of</strong> the major pr<strong>of</strong>essional<br />

periodicals.<br />

The syllabus covers postural strain and overuse injuries;<br />

types, origins, pathology, task design criteria, management<br />

strategies for risk control. Overload injuries; types, origins,<br />

pathology, task design criteria, management strategies for<br />

risk control. System design and developing design strategies<br />

for socio-technical systems; physiological and socio factors.<br />

Human-computer interaction: input device characteristics:<br />

screens, keyboards, mice, graphic tablets, balls, gloves, voice<br />

recogniton, touch screens, new techniques. Output; screen<br />

displays, voice synthesis, printers, character based screens<br />

versus high resolution graphics. Computer control versus user<br />

control, causes <strong>of</strong> user anxiety. Control techniques: windows,<br />

menus, buttons, command keys.<br />

References<br />

Adams, A.S. et a/. (ed) Ergonomics International 88 Proceedings.<br />

London: Taylor and Franc~s, 1988<br />

Chaffin, D. 6. and Anderson. G. Occupational Biomechanics. New<br />

York: Wiley, 1984<br />

Luttgens, K. and Wells, K.F. Kinesiology: Scientific Basis <strong>of</strong> Human<br />

Motion. 7th ed, Philadelphia, Sanders College Publishing, 1982<br />

MM5510 Engineering Technologies<br />

No. <strong>of</strong> hours per week: two houri<br />

Instruction: lectures, workshop and excursions<br />

Assessment: assignments and project<br />

Subject aims and description<br />

This subject aims to explore aspects <strong>of</strong> the design process<br />

critical to an industry maintaining a competitive edge in a<br />

rapidly developing technological society.<br />

Topics will be selected from: management <strong>of</strong> emerging<br />

technologies. Strategic planning for future technology<br />

advances. Market innovation and nichemanship. Planning for<br />

research and development effort. Reliability and<br />

maintainability achievements. Risk assessment for designs<br />

incorporating advanced aspects <strong>of</strong> technology. Development<br />

information systems and configuration management. Special<br />

emerging technologies.<br />

Seminars will be conducted by industrial specialists.<br />

Site visits will be made to local industly.<br />

References<br />

Ang, A. and Tang, W. Probabili@ Concepts in Engineering Planning<br />

and Design kI. I1 - Decision, Risk & Reliability New York: Wiley,<br />

1984<br />

Rhodes. E. and Wield D. (Eds.). Implementing New Technologies,<br />

Choice, Decision and Change in Manufacturing. Oxford: B. Blakewell,<br />

1985<br />

MM55lC Equipment Life Cycle<br />

No. <strong>of</strong> hours per week: two hours<br />

Instruction: lectures, workshops and project<br />

consultations<br />

Subject aims and description<br />

This subjects aims to introduce students to engineering<br />

aspects <strong>of</strong> equipment life cycle from conception through<br />

definition, realisation, integration, commissioning, life usage<br />

and ultimate decommissioningldisposaI.<br />

The syllabus includes: types <strong>of</strong> equipment; fixed and mobile<br />

equipment acquisition and procurement cycle; major<br />

equipment acquisition, minor equipment acquisition,<br />

forecasts, budgets and estimates, conception definition and<br />

realisation. Design research and development, FMECA and<br />

LSA, adaptive design and <strong>of</strong>f-the-shelf design options.<br />

Equipment trailing, testing and demonstration; user<br />

requirements, engineering requirements, reliability,<br />

maintainability, maintenance and logistic support<br />

requirements, trials, tests and demonstration plans and<br />

contracting for reliability.<br />

Maintenance strategy:<br />

Types and approaches, preventive maintenance, condition<br />

monitoring, on condition maintenance and breakdown<br />

maintenance. Maintenance economics and ORTL.<br />

Integration and commissioning process:<br />

Systems management and systems effectiveness, the<br />

operational system, the maintenance sub-system, the training<br />

and documentation package, ISR and inventory stocking<br />

levels, and warrants period.<br />

Maintenance operations:<br />

Maintenance planning and control, work planning, resource<br />

analysis and allocation, plant inventories and records. Repair<br />

parts scaling and spares assessments. Maintenance activities;<br />

repair and performance and condition monitoring, replace,<br />

diagnose, isolate, test, calibrate, overhaul, rebuild,<br />

rectification, downtime and equipment availability.<br />

Maintenance access and creation <strong>of</strong> maintenance windows.<br />

Measures <strong>of</strong> maintenance effectiveness.<br />

Configuration:<br />

Configuration control and modification.<br />

Decommissioning, disposal and system replacement.