LINEAR ALKYLBENZENE SULFONATE (LAS) - UNEP Chemicals

LINEAR ALKYLBENZENE SULFONATE (LAS) - UNEP Chemicals

LINEAR ALKYLBENZENE SULFONATE (LAS) - UNEP Chemicals

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

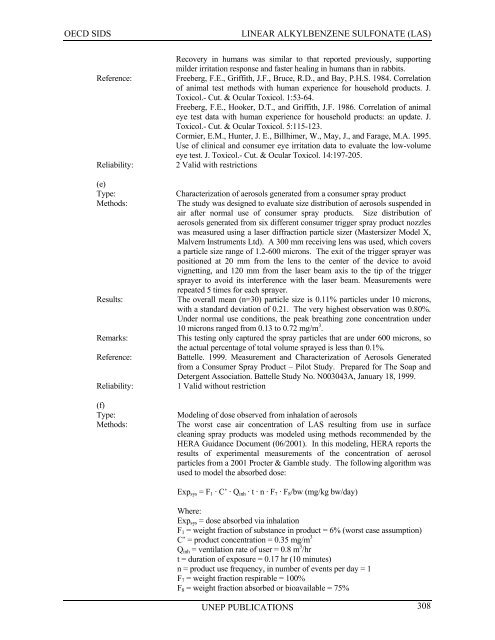

OECD SIDS <strong>LINEAR</strong> <strong>ALKYLBENZENE</strong> <strong>SULFONATE</strong> (<strong>LAS</strong>)<br />

Recovery in humans was similar to that reported previously, supporting<br />

milder irritation response and faster healing in humans than in rabbits.<br />

Reference: Freeberg, F.E., Griffith, J.F., Bruce, R.D., and Bay, P.H.S. 1984. Correlation<br />

of animal test methods with human experience for household products. J.<br />

Toxicol.- Cut. & Ocular Toxicol. 1:53-64.<br />

Freeberg, F.E., Hooker, D.T., and Griffith, J.F. 1986. Correlation of animal<br />

eye test data with human experience for household products: an update. J.<br />

Toxicol.- Cut. & Ocular Toxicol. 5:115-123.<br />

Cormier, E.M., Hunter, J. E., Billhimer, W., May, J., and Farage, M.A. 1995.<br />

Use of clinical and consumer eye irritation data to evaluate the low-volume<br />

eye test. J. Toxicol.- Cut. & Ocular Toxicol. 14:197-205.<br />

Reliability: 2 Valid with restrictions<br />

(e)<br />

Type: Characterization of aerosols generated from a consumer spray product<br />

Methods: The study was designed to evaluate size distribution of aerosols suspended in<br />

air after normal use of consumer spray products. Size distribution of<br />

aerosols generated from six different consumer trigger spray product nozzles<br />

was measured using a laser diffraction particle sizer (Mastersizer Model X,<br />

Malvern Instruments Ltd). A 300 mm receiving lens was used, which covers<br />

a particle size range of 1.2-600 microns. The exit of the trigger sprayer was<br />

positioned at 20 mm from the lens to the center of the device to avoid<br />

vignetting, and 120 mm from the laser beam axis to the tip of the trigger<br />

sprayer to avoid its interference with the laser beam. Measurements were<br />

repeated 5 times for each sprayer.<br />

Results: The overall mean (n=30) particle size is 0.11% particles under 10 microns,<br />

with a standard deviation of 0.21. The very highest observation was 0.80%.<br />

Under normal use conditions, the peak breathing zone concentration under<br />

10 microns ranged from 0.13 to 0.72 mg/m 3 .<br />

Remarks: This testing only captured the spray particles that are under 600 microns, so<br />

the actual percentage of total volume sprayed is less than 0.1%.<br />

Reference: Battelle. 1999. Measurement and Characterization of Aerosols Generated<br />

from a Consumer Spray Product – Pilot Study. Prepared for The Soap and<br />

Detergent Association. Battelle Study No. N003043A, January 18, 1999.<br />

Reliability: 1 Valid without restriction<br />

(f)<br />

Type: Modeling of dose observed from inhalation of aerosols<br />

Methods: The worst case air concentration of <strong>LAS</strong> resulting from use in surface<br />

cleaning spray products was modeled using methods recommended by the<br />

HERA Guidance Document (06/2001). In this modeling, HERA reports the<br />

results of experimental measurements of the concentration of aerosol<br />

particles from a 2001 Procter & Gamble study. The following algorithm was<br />

used to model the absorbed dose:<br />

Expsys = F1 · C’ · Qinh · t · n · F7 · F8/bw (mg/kg bw/day)<br />

Where:<br />

Expsys = dose absorbed via inhalation<br />

F1 = weight fraction of substance in product = 6% (worst case assumption)<br />

C’ = product concentration = 0.35 mg/m 3<br />

Qinh = ventilation rate of user = 0.8 m 3 /hr<br />

t = duration of exposure = 0.17 hr (10 minutes)<br />

n = product use frequency, in number of events per day = 1<br />

F7 = weight fraction respirable = 100%<br />

F8 = weight fraction absorbed or bioavailable = 75%<br />

<strong>UNEP</strong> PUBLICATIONS 308