Zbornik radova Koridor 10 - Kirilo SaviÄ

Zbornik radova Koridor 10 - Kirilo SaviÄ

Zbornik radova Koridor 10 - Kirilo SaviÄ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3rd International Scientific and Professional Conference<br />

CORRIDOR <strong>10</strong> - a sustainable way of integrations<br />

5.1 Maintenance of the upper part of the rail head<br />

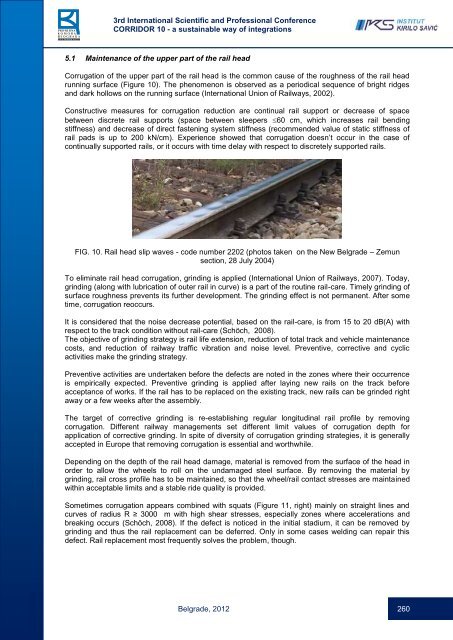

Corrugation of the upper part of the rail head is the common cause of the roughness of the rail head<br />

running surface (Figure <strong>10</strong>). The phenomenon is observed as a periodical sequence of bright ridges<br />

and dark hollows on the running surface (International Union of Railways, 2002).<br />

Constructive measures for corrugation reduction are continual rail support or decrease of space<br />

between discrete rail supports (space between sleepers 60 cm, which increases rail bending<br />

stiffness) and decrease of direct fastening system stiffness (recommended value of static stiffness of<br />

rail pads is up to 200 kN/cm). Experience showed that corrugation doesn’t occur in the case of<br />

continually supported rails, or it occurs with time delay with respect to discretely supported rails.<br />

FIG. <strong>10</strong>. Rail head slip waves - code number 2202 (photos taken on the New Belgrade – Zemun<br />

section, 28 July 2004)<br />

To eliminate rail head corrugation, grinding is applied (International Union of Railways, 2007). Today,<br />

grinding (along with lubrication of outer rail in curve) is a part of the routine rail-care. Timely grinding of<br />

surface roughness prevents its further development. The grinding effect is not permanent. After some<br />

time, corrugation reoccurs.<br />

It is considered that the noise decrease potential, based on the rail-care, is from 15 to 20 dB(A) with<br />

respect to the track condition without rail-care (Schöch, 2008).<br />

The objective of grinding strategy is rail life extension, reduction of total track and vehicle maintenance<br />

costs, and reduction of railway traffic vibration and noise level. Preventive, corrective and cyclic<br />

activities make the grinding strategy.<br />

Preventive activities are undertaken before the defects are noted in the zones where their occurrence<br />

is empirically expected. Preventive grinding is applied after laying new rails on the track before<br />

acceptance of works. If the rail has to be replaced on the existing track, new rails can be grinded right<br />

away or a few weeks after the assembly.<br />

The target of corrective grinding is re-establishing regular longitudinal rail profile by removing<br />

corrugation. Different railway managements set different limit values of corrugation depth for<br />

application of corrective grinding. In spite of diversity of corrugation grinding strategies, it is generally<br />

accepted in Europe that removing corrugation is essential and worthwhile.<br />

Depending on the depth of the rail head damage, material is removed from the surface of the head in<br />

order to allow the wheels to roll on the undamaged steel surface. By removing the material by<br />

grinding, rail cross profile has to be maintained, so that the wheel/rail contact stresses are maintained<br />

within acceptable limits and a stable ride quality is provided.<br />

Sometimes corrugation appears combined with squats (Figure 11, right) mainly on straight lines and<br />

curves of radius R ≥ 3000 m with high shear stresses, especially zones where accelerations and<br />

breaking occurs (Schöch, 2008). If the defect is noticed in the initial stadium, it can be removed by<br />

grinding and thus the rail replacement can be deferred. Only in some cases welding can repair this<br />

defect. Rail replacement most frequently solves the problem, though.<br />

Belgrade, 2012 260