Zbornik radova Koridor 10 - Kirilo SaviÄ

Zbornik radova Koridor 10 - Kirilo SaviÄ

Zbornik radova Koridor 10 - Kirilo SaviÄ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3rd International Scientific and Professional Conference<br />

CORRIDOR <strong>10</strong> - a sustainable way of integrations<br />

welding, crane operation and material handling. OSHA [6] has been insisting on mandatory training for<br />

safer working environments, with regards to the following:<br />

provision of adequate worker training;<br />

use of proper personnel protective equipment;<br />

obedience to fire protection measures; and<br />

arrangements for appropriate emergency action teams such as firefighting, rescue, first aid,<br />

pollution prevention and other services.<br />

The combustible wastes obtained from scrapped vessels are regarded as an alternative fuel, and can<br />

be used as a fuel by proper gasification or incineration with proper pollution protective measures. The<br />

energy obtained can be used for power generation.<br />

2. DISMANTLING STAGES<br />

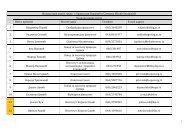

Decommissioning for disposal is a step by step process (illustrated in Scheme 1):<br />

Decommissioning and sale<br />

Inventory of onboard<br />

hazardous/ polluting wastes<br />

• (Removal/ cleaning – liquids,<br />

including fuels and oils)<br />

• Securing<br />

(Removal of equipment)<br />

The dismantling process<br />

(Inventory of onboard<br />

hazardous/ polluting wastes)<br />

• Removal/ cleaning– liquids,<br />

including fuels and oils<br />

• Securing<br />

Removal of equipment<br />

Removal of<br />

hazardous/polluting<br />

substances<br />

Dismantling<br />

Sorting for reuse,<br />

recycling and disposal<br />

Storage, recycling and<br />

disposal<br />

Storage, recycling and<br />

disposal<br />

Scheme 1. Block diagram of decommissioning and dismantling stages<br />

Basic rules and labor safety and occupational health during dismantling of vessels<br />

Shipbreaking is one of the most hazardous activities of shipping industry. This is due to the structural<br />

complexity of the ships and due to the possible exposures to asbestos, polychlorinated biphenyls<br />

(PCBs), lead, hazardous materials and chemicals, as well as excess noise and fire and explosions. A<br />

report prepared by the U.S. Department of Labor Occupational Safety and Health Administration for a<br />

national program on reduction of workplace hazards for shipbreaking operations, hazardous activities<br />

related to shipbreaking are listed as follows [6]:<br />

Entry into confined, enclosed and other dangerous atmospheres<br />

Paint removal<br />

Metal cutting and disposing<br />

Powered industrial truck operations<br />

Working on elevated surfaces<br />

Bilge and ballast water removal<br />

Oil and fuel removal and tank cleaning<br />

Removal and disposal of ship’s machinery<br />

Operations involving cranes, gear, and material handling equipment<br />

Cutting and welding operations and use of compressed gas and<br />

Activities involving scaffolds, ladders and working services.<br />

Belgrade, 2012 284