SV-iS7 User Manual - Inverter Drive Supermarket

SV-iS7 User Manual - Inverter Drive Supermarket

SV-iS7 User Manual - Inverter Drive Supermarket

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

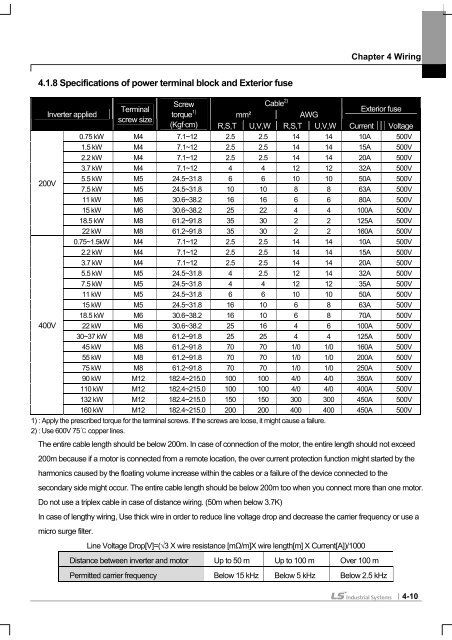

4.1.8 Specifications of power terminal block and Exterior fuse<br />

<strong>Inverter</strong> applied<br />

200V<br />

Terminal<br />

screw size<br />

Screw<br />

torque 1)<br />

Cable 2)<br />

mm² AWG<br />

Chapter 4 Wiring<br />

Exterior fuse<br />

(Kgf·cm) R,S,T U,V,W R,S,T U,V,W Current Voltage<br />

0.75 kW M4 7.1~12 2.5 2.5 14 14 10A 500V<br />

1.5 kW M4 7.1~12 2.5 2.5 14 14 15A 500V<br />

2.2 kW M4 7.1~12 2.5 2.5 14 14 20A 500V<br />

3.7 kW M4 7.1~12 4 4 12 12 32A 500V<br />

5.5 kW M5 24.5~31.8 6 6 10 10 50A 500V<br />

7.5 kW M5 24.5~31.8 10 10 8 8 63A 500V<br />

11 kW M6 30.6~38.2 16 16 6 6 80A 500V<br />

15 kW M6 30.6~38.2 25 22 4 4 100A 500V<br />

18.5 kW M8 61.2~91.8 35 30 2 2 125A 500V<br />

22 kW M8 61.2~91.8 35 30 2 2 160A 500V<br />

0.75~1.5kW M4 7.1~12 2.5 2.5 14 14 10A 500V<br />

2.2 kW M4 7.1~12 2.5 2.5 14 14 15A 500V<br />

3.7 kW M4 7.1~12 2.5 2.5 14 14 20A 500V<br />

5.5 kW M5 24.5~31.8 4 2.5 12 14 32A 500V<br />

7.5 kW M5 24.5~31.8 4 4 12 12 35A 500V<br />

11 kW M5 24.5~31.8 6 6 10 10 50A 500V<br />

15 kW M5 24.5~31.8 16 10 6 8 63A 500V<br />

18.5 kW M6 30.6~38.2 16 10 6 8 70A 500V<br />

400V 22 kW M6 30.6~38.2 25 16 4 6 100A 500V<br />

30~37 kW M8 61.2~91.8 25 25 4 4 125A 500V<br />

45 kW M8 61.2~91.8 70 70 1/0 1/0 160A 500V<br />

55 kW M8 61.2~91.8 70 70 1/0 1/0 200A 500V<br />

75 kW M8 61.2~91.8 70 70 1/0 1/0 250A 500V<br />

90 kW M12 182.4~215.0 100 100 4/0 4/0 350A 500V<br />

110 kW M12 182.4~215.0 100 100 4/0 4/0 400A 500V<br />

132 kW M12 182.4~215.0 150 150 300 300 450A 500V<br />

160 kW M12 182.4~215.0 200 200 400 400 450A 500V<br />

1) : Apply the prescribed torque for the terminal screws. If the screws are loose, it might cause a failure.<br />

2) : Use 600V 75℃ copper lines.<br />

The entire cable length should be below 200m. In case of connection of the motor, the entire length should not exceed<br />

200m because if a motor is connected from a remote location, the over current protection function might started by the<br />

harmonics caused by the floating volume increase within the cables or a failure of the device connected to the<br />

secondary side might occur. The entire cable length should be below 200m too when you connect more than one motor.<br />

Do not use a triplex cable in case of distance wiring. (50m when below 3.7K)<br />

In case of lengthy wiring, Use thick wire in order to reduce line voltage drop and decrease the carrier frequency or use a<br />

micro surge filter.<br />

Line Voltage Drop[V]=(√3 X wire resistance [mΩ/m]X wire length[m] X Current[A])/1000<br />

Distance between inverter and motor Up to 50 m Up to 100 m Over 100 m<br />

Permitted carrier frequency Below 15 kHz Below 5 kHz Below 2.5 kHz<br />

4-10