- Page 1 and 2:

II. İLERİ TEKNOLOJİLER ÇALIŞTA

- Page 3 and 4:

BİLGİ NOTU VE TEŞEKKÜR Bahçeş

- Page 5 and 6:

İÇİNDEKİLER Bilgi Notu ve Teşe

- Page 7 and 8:

BACA GAZINDAKİ GİZLİ ISIYI KULLA

- Page 9 and 10: RÜZGAR ENERJİSİ ÜRETİM SİSTEM

- Page 11 and 12: CRITERION: ONLINE YAZMA DEĞERLEND

- Page 13 and 14: ÖNSÖZ Bu çalışmalardan bir son

- Page 15 and 16: AÇIŞ KONUŞMALARI KONGRE AÇILIŞ

- Page 17 and 18: 2006, 2007 yıllarında Ulusal ve U

- Page 19 and 20: Faaliyeti kurumsal olarak organize

- Page 21 and 22: İLERİ TEKNOLOJİLER STRATEJİSİ

- Page 23 and 24: PLAZMA YAKIT PİLLERİ Prof. Dr. Be

- Page 25 and 26: AÇIŞ KONUŞMALARI Prof. Dr. Şena

- Page 27 and 28: öğrenim görmüş kişilerin gene

- Page 29: SÖZLÜ BİLDİRİLER PANEL I SANAY

- Page 32 and 33: 32 ihracatı içinde imalat sanayi

- Page 34 and 35: 34 rine yönelik sektörel strateji

- Page 36 and 37: 36 Bu doğrultuda, Makina Sektörü

- Page 39 and 40: KÜBİK BOR NİTRÜR (CBN) KAPLAMAL

- Page 41: ATILIM ÜNİVERSİTESİNDE İLERİ

- Page 45 and 46: İLERİ TEKNOLOJİ Mİ? YENİ TEKNO

- Page 47: ATILIM ÜNİVERSİTESİ BÜNYESİND

- Page 50 and 51: 50 yapılan tüm çalışmalarımı

- Page 53 and 54: TEKNOLOJİ ÇALIŞTAYI VE BAHÇEŞE

- Page 55: Teknolojik gelişme ve ilerleme, ü

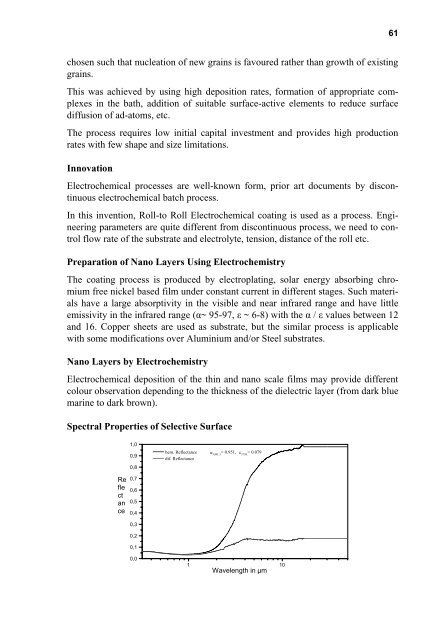

- Page 59: FROM FUNDAMENTAL TO APPLIED ELECTRO

- Page 63: Testing and Accreditation of The Se

- Page 66 and 67: 66 each step. The analysis is carri

- Page 68 and 69: 68 According to the cumulative ener

- Page 71 and 72: NİĞDE ÜNİVERSİTESİNDE KATI OK

- Page 73 and 74: tabakası olmak üzere iki ayrı ta

- Page 75 and 76: genleşme farkı hücrenin eğilmes

- Page 77 and 78: soğutulması ve dinamik yükleme k

- Page 79 and 80: 3.1. PEM elektrolizörlerde Görün

- Page 81 and 82: HİDROJEN SÜLFÜRDEN ELEKTROLİZ Y

- Page 83 and 84: Çevre kirliliği açısından da s

- Page 85 and 86: [11]. Saf H2S beslenen ve 135 kPa,

- Page 87 and 88: 5. Sonuç Araştırmalar elektroliz

- Page 89 and 90: SÜREKLİ HİDROJEN ÇEVRİMİ AMAC

- Page 91 and 92: Na2B4O7 CaB3O4(OH)3H2O Şekil 1. Hi

- Page 93 and 94: 3. NaBH4’ün Hidrolizi ve Hidroje

- Page 95 and 96: NaBH4 + 6H2O → 4H2 + NaBO2.4H2O (

- Page 97 and 98: negatif yüklüdür ve yüzeyi (H

- Page 99 and 100: NaBO2 geri dönüşümünde karbon

- Page 101 and 102: 101 Çalışmalar bilyeli değirmen

- Page 103 and 104: 103 FTIR analizi NaBH4 varlığın

- Page 105 and 106: 105 10. Lyttle, D.A.; Jensen, E.H.;

- Page 107 and 108: PANEL IV SANAYİ, EĞİTİM, BİLİ

- Page 109 and 110: TEKNOGİRİŞİM SERMAYESİ DESTEĞ

- Page 111 and 112:

Başvuru Şekli Dokümanlar 111

- Page 113 and 114:

Ön Başvuru Dosyası � Başvuru

- Page 115 and 116:

EĞİTİM DURUMLARINA GÖRE DAĞILI

- Page 117 and 118:

ÜNİVERSİTE-SANAYİ İŞBİRLİĞ

- Page 119 and 120:

Üniversite-Sanayi İşbirliğinde

- Page 121 and 122:

121 nuda çalışma yapmak isteyen

- Page 123 and 124:

EĞİTİM ORTAMINA YENİLEŞİMCİ

- Page 125 and 126:

125 150 yıl önce kullanılmaya ba

- Page 127 and 128:

127 cihazlar olmaktaydı. Tüm bu e

- Page 129 and 130:

129 eğitime özel üretilmiş dona

- Page 131 and 132:

131 üzerinden internete ulaşarak

- Page 133 and 134:

133 Ülkemizde buluşunun yapılmas

- Page 135 and 136:

ENERJİ SEKTÖRÜNÜN GÖRÜNÜMÜ

- Page 137 and 138:

Dünya: Yenilenebilir ve Yatırıml

- Page 139 and 140:

Türkiye: Elektrik Santralleri ve

- Page 141 and 142:

2011 Yılında İşletmeye Açılan

- Page 143 and 144:

PANEL V NÜKLEER ENERJİDE İLERİ

- Page 145 and 146:

Özet EYLEMSİZLİKLE TUTUKLAMA FÜ

- Page 147 and 148:

Protiyum Döteryum Trityum Proton E

- Page 149 and 150:

149 Füzyon sisteminin (5) ile veri

- Page 151 and 152:

151 Manyetik tutuklamada çok güç

- Page 153 and 154:

ulunur. Son denklemde cs≈10 6 m/s

- Page 155 and 156:

155 ışınları yayınlar. Bu x ı

- Page 157 and 158:

BACA GAZINDAKİ GİZLİ ISIYI KULLA

- Page 159 and 160:

159 Türkiye’de yılda 750.000 ko

- Page 161 and 162:

161 Şekilde de görüldüğü üze

- Page 163 and 164:

HİDROJEN ENERJİSİ HAKKINDA DÜŞ

- Page 165 and 166:

165 Hidrojen enerjisi bu kriterleri

- Page 167 and 168:

Söz Konusu Kongrelerin Katılımc

- Page 169 and 170:

Sanayinin ve Enerjinin Geleceğinde

- Page 171 and 172:

YENİ NESİL NÜKLEER REAKTÖRLER V

- Page 173 and 174:

YAKIT PİLLERİ TEKNOLOJİLERİ 173

- Page 175 and 176:

Özet KATI OKSİT YAKIT PİLLERİND

- Page 177 and 178:

2. Deneysel Düzenek 177 Bütün s

- Page 179 and 180:

Tablo 1. Deneyde kullanılan malzem

- Page 181 and 182:

4. Sonuçlar ve Tartışma 181 Sonu

- Page 183 and 184:

Özet KATI OKSİT YAKIT PİLLERİ R

- Page 185 and 186:

185 olmadığı fakat polarizasyon

- Page 187 and 188:

Enerji Korunumu Enerji korunum denk

- Page 189 and 190:

Anot kanalı giriş basıncı (Pa)

- Page 191 and 192:

191 Hasar miktarının pil performa

- Page 193 and 194:

193 [17] Gunji A., Wen C., Otomo J.

- Page 195 and 196:

KATOT ÜRETİM PARAMETRELERİN KATI

- Page 197 and 198:

197 yüzey alanı ve porozitesine b

- Page 199 and 200:

199 Bütün örneklerde iki ark gö

- Page 201 and 202:

3.1.2. KİT Kalınlığının Etkis

- Page 203 and 204:

3.2.2. KAT Gözenekliliğinin Perfo

- Page 205 and 206:

[9] Gruzdev, A. I., Sov. Electroche

- Page 207 and 208:

PEM (Proton Exchange Membrane) ELEK

- Page 209 and 210:

209 hidrojen iyonları katoda geçm

- Page 211 and 212:

211 Nordlund ve arkadaşları [12]

- Page 213 and 214:

213 Ancak sıkıştırma plakası o

- Page 215 and 216:

215 ZnS sintilatör, detektör olar

- Page 217 and 218:

3.2.3. 25 cm 2 Köşeli Dizayn 217

- Page 219 and 220:

3.4. Deneysel Sonuçlar 219 Deneyle

- Page 221 and 222:

221 Şekil 9. Alınan nötron datal

- Page 223 and 224:

223 [3] Selamet O F, Becerikli F, A

- Page 225 and 226:

225 YAKIT PİLİ TEKNOLOJİSİ, TÜ

- Page 227 and 228:

2.2. PEMYP Konusunda Gerçekleştir

- Page 229 and 230:

2.2.4. Polimer Elektrolit Membranl

- Page 231 and 232:

2.3.2. Sabit Uygulamalar İçin Do

- Page 233 and 234:

Şekil 9. SBH Yakıt Pilli Araç 23

- Page 235 and 236:

3. Sonuç 235 Yakıt pilleri üreti

- Page 237 and 238:

KATI OKSİT YAKIT PİLLERİNDE (KOY

- Page 239 and 240:

239 KOYP’nin yüksek sıcaklıkta

- Page 241 and 242:

241 Şekil 2’de görüldüğü gi

- Page 243 and 244:

243 krom uçuculuğu, oluşan oksit

- Page 245 and 246:

Özet KATI OKSİT YAKIT PİLLERİ

- Page 247 and 248:

Test düzeneği şu şekilde hazır

- Page 249 and 250:

249 lar kullanılarak testler gerç

- Page 251 and 252:

Kaynakça 251 [1] M. Mori, Y. Liu,

- Page 253 and 254:

Özet KATI OKSİT YAKIT PİLLERİ

- Page 255 and 256:

255 silikat, borat ve boronsilikatl

- Page 257 and 258:

geçiş sıcaklığı(Tg), oluşan

- Page 259 and 260:

259 sözkonusu olamamaktadır. Yap

- Page 261 and 262:

Özet KATI OKSİT YAKIT HÜCRESİND

- Page 263 and 264:

263 olarak ortaya koyabilen bir mat

- Page 265 and 266:

Anot gaz kanalı Katot gaz kanalı

- Page 267 and 268:

Eşitlik (11)’de, viskoziteyi ve

- Page 269 and 270:

269 Anot (17) Katot (18) 3.2. Sın

- Page 271 and 272:

271 Üretilen tek hücreli KOYP ça

- Page 273 and 274:

Şekil 9. (Fırın Sıcaklığı: 8

- Page 275 and 276:

5. Sonuçlar Şekil 13. Performans

- Page 277 and 278:

ALTERNATİF ENERJİLER VE MAKİNE T

- Page 279 and 280:

OPTİK TEKNOLOJİSİNİN ÖLÇÜM T

- Page 281 and 282:

(a) (b) Şekil 1. Şebekeye enerji

- Page 283 and 284:

Odaklı Cisimden Yansımalı Tip: C

- Page 285 and 286:

ÜRETİMDE KALİTE ARTIŞINA BAĞLI

- Page 287 and 288:

Sonuç � Eksen hızları, ivmelen

- Page 289 and 290:

289 bir uygulamanın Internet üzer

- Page 291 and 292:

TAKIM TEZGAHLARI SEKTÖRÜNÜN GELE

- Page 293 and 294:

Sanayileşmek gelişmiş ülke olma

- Page 295 and 296:

295 kullanımının özendirilmesi,

- Page 297 and 298:

PEYNİR ALTI SUYUNDAN TEK KADEMELİ

- Page 299 and 300:

299 Bu çalışmada süt ve süt ü

- Page 301 and 302:

Tablo 1. Tek kademeli sistemde %5 k

- Page 303 and 304:

Biyogaz Üretimi (lt/gün) Gaz Kons

- Page 305 and 306:

305 Tek kademeli sistemde; 80 g ine

- Page 307 and 308:

ULAŞTIRMA SEKTÖRÜNDE ALTERNATİF

- Page 309 and 310:

309 Elektrikli araçlarda ortak nok

- Page 311 and 312:

Sekil 5. Yakıt pilli araç örnekl

- Page 313 and 314:

313 Yenilenebilir enerjinin, Türki

- Page 315 and 316:

Özet ENERJİ’DE GELİŞMELER - F

- Page 317 and 318:

� Biyoenerji - Biyoyakıt, � Ta

- Page 319 and 320:

319 � Enerji Verimli Evler ve Bin

- Page 321 and 322:

Özet YENİLENEBİLİR ENERJİ TEKN

- Page 323 and 324:

323 kullanılabilir olması, kullan

- Page 325 and 326:

325 Şekil 1. de dünyanın rüzgar

- Page 327 and 328:

3.4. Jeotermal Enerji 327 Jeotermal

- Page 329 and 330:

329 elde edilmesi esnasında su buh

- Page 331 and 332:

331 Yukarıdaki tablolara baktığ

- Page 333 and 334:

Özet RÜZGAR ENERJİSİ ÜRETİM S

- Page 335 and 336:

335 aşmazken, %16.11'inde 30-40 W/

- Page 337 and 338:

Şekil 1. Tipik bir rüzgâr türbi

- Page 339 and 340:

339 böyle bir ömür sorunu yoktur

- Page 341 and 342:

341 bozulması gibi kısa ve uzun v

- Page 343 and 344:

Özet ENERJİ EKONOMİSİ UYGULAMAL

- Page 345 and 346:

Şekil 1. Türkiye'de binalarda kul

- Page 347 and 348:

347 Bu nedenle enerji sistemlerinin

- Page 349 and 350:

349 konumundadır. Güneş alan yü

- Page 351 and 352:

351 uygulama yöntemlerine göre je

- Page 353 and 354:

[5] Anonim, 2006. Viessmann, Techni

- Page 355 and 356:

Özet TÜRKİYE’DE RÜZGAR ENERJ

- Page 357 and 358:

357 olarak bilinen hidrolik, rüzga

- Page 359 and 360:

Rüzgar Enerjisinin Zararları �

- Page 361 and 362:

� Gerekli onay ve izinlerin alın

- Page 363 and 364:

Çizelge 5.2002 Yılı İtibarıyla

- Page 365 and 366:

365 Avrupa Rüzgar Enerjisi Birliğ

- Page 367 and 368:

[7]. ÖNEN, E. 1985. Havalandırma

- Page 369 and 370:

TARİHSEL PERSPEKTİFTEN İNOVASYON

- Page 371 and 372:

371 payları, boşa yapılan yatır

- Page 373 and 374:

373 sağlayan girişimler oluşturm

- Page 375 and 376:

375 Nükleer bir bombayla uçak gem

- Page 377 and 378:

377 Bu ambargo kaldırılsa da Avru

- Page 379 and 380:

379 Daha önce görülmemiş Pekin

- Page 381 and 382:

ÜRETİM SEKTÖRÜNDEKİ FİRMALAR

- Page 383 and 384:

2. Yaşam Döngüsü Değerlendirme

- Page 385 and 386:

385 Bu denklemde S etki puanı, C k

- Page 387 and 388:

4. SuSaaS Çerçevesi 387 Üretim y

- Page 389 and 390:

4.3. Eko-iyileştirme 389 Eko-iyile

- Page 391 and 392:

Özet KATMA DEĞERİ YÜKSEK ÜRÜN

- Page 393 and 394:

(ERP)) sistemleriyle daha uyumlu ç

- Page 395 and 396:

395 mıştır. PRODNET’de değiş

- Page 397 and 398:

397 tirdikleri yapıya çok benzerl

- Page 399 and 400:

Uygulama Alanları 399 Organize San

- Page 401 and 402:

Kaynaklar 401 [1] Al- Safi, Y. And

- Page 403 and 404:

Özet SANAYİ AR-GE PROJELERİ DEĞ

- Page 405 and 406:

2.1. Gizlilik ve Güvenlik 405 Site

- Page 407 and 408:

yapılmış olmaktadır. Destek ver

- Page 409 and 410:

Bazı Örnek Projeler; 409

- Page 411 and 412:

Destek Programları; Örnek bir pro

- Page 413 and 414:

Test Sonucu; 413 4. Sonuçlar ve Ö

- Page 415 and 416:

415 [14] OĞUR A., KARAKAYA Ç. "Ü

- Page 417 and 418:

MALZEME UYGULAMALARI VE İLERİ TEK

- Page 419 and 420:

Özet FONKSİYONEL YORULMA SONRASIN

- Page 421 and 422:

Şekil 1. Şekil Bellekli Alaşıml

- Page 423 and 424:

423 Şekil 4’te görüldüğü gi

- Page 425 and 426:

Tablo 2. Yorulmaya uğramamış ŞB

- Page 427 and 428:

427 Şekil 13 fonksiyonel yorulma d

- Page 429 and 430:

429 Şekil 17. Matrisin BSE kullan

- Page 431 and 432:

Şekil 21. 80 fonksiyonel yorulma

- Page 433 and 434:

investigations via in situ optical

- Page 435 and 436:

POLİVİNİL BORAT/POLİ(METİL MET

- Page 437 and 438:

(a) (b) Resim 1. (a) PVA ve Borik a

- Page 439 and 440:

439 deneylerinde polivinil borat so

- Page 441 and 442:

Kaynaklar 1. Gopal R., Zuwei, M.; K

- Page 443 and 444:

Özet YÜKSEK BASINÇ PEM ELEKTROL

- Page 445 and 446:

445 Katot bölgesine geçen hidroje

- Page 447 and 448:

447 yüksek gaz basıncının elde

- Page 449 and 450:

4. Sonuçlar 449 Bu çalışmada y

- Page 451 and 452:

MİKROALAŞIMLI ÇELİKLERDE GERİN

- Page 453 and 454:

453 Diğer yandan, mikroalaşımlı

- Page 455 and 456:

3.1. Deformasyon Sıcaklığının

- Page 457 and 458:

457 katkılı çökelmenin meydana

- Page 459 and 460:

459 15. I. Tamura, C. Ouchi, T. Tan

- Page 461 and 462:

ERİYİK SAVURMA DÖKÜM YÖNTEMİ

- Page 463 and 464:

463 (martenzitik/beynitik oluşum)

- Page 465 and 466:

465 grafit, ötektik karbürler ve

- Page 467 and 468:

467 (a) (b) Şekil 4. Aşınma test

- Page 469 and 470:

NİOBYUM İLE ALAŞIMLANDIRILMIŞ Y

- Page 471 and 472:

471 Yüksek hız çeliklerinin mikr

- Page 473 and 474:

(a) (b) 473 (c) (d) Şekil 1. Parla

- Page 475 and 476:

475 kısmen tane sınırlarında ye

- Page 477 and 478:

477 Bu çelik aynı zamanda perklor

- Page 479 and 480:

479 (a) (b) Şekil 9. Perklorik asi

- Page 481 and 482:

Özet ESR YÖNTEMİ İLE ÜRETİLM

- Page 483 and 484:

2.2. Isıl İşlem Uygulamaları ve

- Page 485 and 486:

tilmiştir. Kırılma tokluğu aç

- Page 487 and 488:

487 dönüşüm göstermiştir. Ço

- Page 489 and 490:

489 [3] Roberts, G., Krauss, G., Ke

- Page 491 and 492:

Özet SU VERİLMİŞ VE TEMPERLENM

- Page 493 and 494:

2.2. Balistik Test 493 Balistik at

- Page 495 and 496:

Şekil 2. AISI 4340 çeliği ile me

- Page 497 and 498:

Şekil 5. Deneysel çeliğe ait mik

- Page 499 and 500:

499 (a) (b) Şekil 7. (a) Mermi ile

- Page 501 and 502:

Kaynaklar 501 [1] Lane, R., Craig,

- Page 503 and 504:

SIVI FAZ SİNTERLENMİŞ SiC ESASLI

- Page 505 and 506:

505 Bir başka çalışmada slip d

- Page 507 and 508:

Tablo 3. Sıvı faz sinterlenmiş n

- Page 509 and 510:

509 Şekil 4’te ışık mikroskob

- Page 511 and 512:

BİR TELESKOP YANSITICISININ SLİP

- Page 513 and 514:

513 Slip döküm öncesi kalıp haz

- Page 515 and 516:

515 Slip döküm sonrası parçanı

- Page 517 and 518:

Ön-sinterleme 517 Şekil 6. Disper

- Page 519 and 520:

EĞİTİM / DİL ve BİLGİ TEKNOLO

- Page 521 and 522:

Özet EĞİTİM VE İLERİ TEKNOLOJ

- Page 523 and 524:

523 Simülasyonlar ve modellemeler,

- Page 525 and 526:

yüzyılda yaratıcılık ve yenili

- Page 527 and 528:

527 olur. Teknik eğitimin genişle

- Page 529 and 530:

İLERİ TEKNOLOJİ OKURYAZARLIĞI S

- Page 531 and 532:

531 ğının yanılgısı içinde,

- Page 533 and 534:

İLERİ TEKNOLOJİLERİN SUNDUĞU A

- Page 535 and 536:

535 yine bireyin kendi gerçek yaş

- Page 537 and 538:

537 arasında kelime işlemciler ve

- Page 539 and 540:

539 bulunan öğrenenler üzerinde

- Page 541 and 542:

541 Yabancı Dil Öğrenmede Öğre

- Page 543 and 544:

543 meleridir. Diğer bir ifadeyle

- Page 545 and 546:

Özet CRITERION: ONLINE YAZMA DEĞE

- Page 547 and 548:

547 Bunun yanı sıra, bu teknoloji

- Page 549 and 550:

Kaynakça Burstein, J., Kukich, K.,

- Page 551 and 552:

Özet TEKNOLOJİ ÇAĞINDA İNGİL

- Page 553 and 554:

553 mektedir” (İlter, t.y.). Bil

- Page 555 and 556:

555 öğrenmek istemelerindeki en b

- Page 557 and 558:

Özet AKDENİZ’DEKİ YETKİ ALANL

- Page 559 and 560:

559 1973-1982 yılları arasında

- Page 561 and 562:

561 sınırlandırılması çerçev

- Page 563 and 564:

563 arasında yer almaktadır. Böl

- Page 565 and 566:

565 girişimleri, 30 Doğu Akdeniz

- Page 567 and 568:

5. Kıbrıs’ın Kuzey Bölgesinde

- Page 569 and 570:

569 Türkiye arasında karşılıkl

- Page 571 and 572:

571 durumdadır. Mısır ise, anaka

- Page 573 and 574:

573 İkinci olarak, bölgenin coğr

- Page 575 and 576:

575 nitelikler açısından tarafla

- Page 577 and 578:

Coğrafya Dışı Unsurların Etkil

- Page 579 and 580:

579 oynamaktadırlar. Deniz alanlar

- Page 581 and 582:

Giriş GIDA BİLİMİNDE SON TEKNOL

- Page 583 and 584:

583 Genetiği Değiştirilmiş Orga

- Page 585 and 586:

585 koruma ve iyileştirmek oluştu

- Page 587 and 588:

Darbeli Elektrik Alanı 587 Yüksek

- Page 589 and 590:

589 ten gelen güven duygusuyla tü

- Page 591 and 592:

591 8. Butz, P., Needs, E. C., Baro

- Page 593 and 594:

593 39. Lassen, J., Madsen, K. H.,

- Page 595 and 596:

ERGENLERİN SİBER AKRAN ZORBALIĞI

- Page 597 and 598:

597 Tüm bunların yanısıra, ara

- Page 599 and 600:

599 arasında da anlamlı bir farkl

- Page 601 and 602:

601 na maruz kaldıklarını belirt

- Page 603 and 604:

603 araştırmada belirttiği gibi,

- Page 605 and 606:

Kaynakça 605 1. Arıcak, T. Siyahh

- Page 607 and 608:

607 33. Subrahmanyam, K & Greenfiel

- Page 609 and 610:

Özet P3HT ve P3HT+PCBM FİLMLERİN

- Page 611 and 612:

(a) (b) Şekil 1. UV-Visible absorb

- Page 613 and 614:

Teşekkür 613 Bu çalışma 110T35

- Page 615 and 616:

Özet MOBİL TELEFON İÇİN J2ME

- Page 617 and 618:

617 Veri alışverişi sırasında

- Page 619 and 620:

Özet STOK YÖNETİMİ SÜRECİNDE

- Page 621 and 622:

621 Stok yönetiminde RFID teknoloj

- Page 623 and 624:

ESTABLISMENT of A WIND & PV DRIVEN

- Page 625 and 626:

625 modules from 50 to 150 Wp, they

- Page 627 and 628:

4. References 627 1. E.Mathioulakis

- Page 629 and 630:

YAZAR DİZİNİ Abdullah MAT 245 Ab