The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 11 – Laminating and B<strong>on</strong>ding Techniques 97<br />

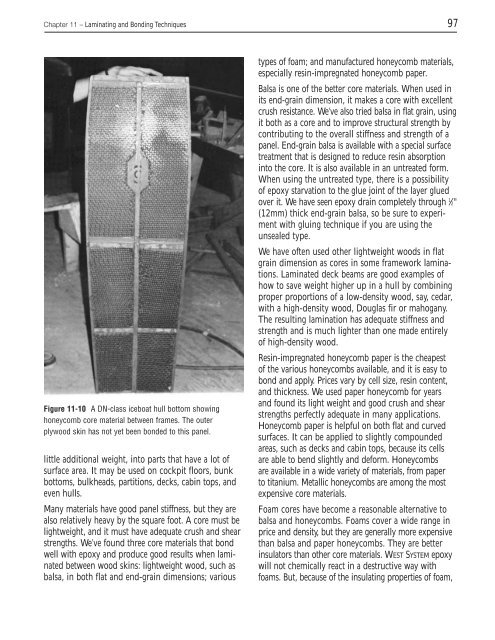

Figure 11-10 A DN-class iceboat hull bottom showing<br />

h<strong>on</strong>eycomb core material between frames. <str<strong>on</strong>g>The</str<strong>on</strong>g> outer<br />

plywood skin has not yet been b<strong>on</strong>ded to this panel.<br />

little additi<strong>on</strong>al weight, into parts that have a lot of<br />

surface area. It may be used <strong>on</strong> cockpit floors, bunk<br />

bottoms, bulkheads, partiti<strong>on</strong>s, decks, cabin tops, and<br />

even hulls.<br />

Many materials have good panel stiffness, but they are<br />

also relatively heavy by the square foot. A core must be<br />

lightweight, and it must have adequate crush and shear<br />

strengths. We’ve found three core materials that b<strong>on</strong>d<br />

well with epoxy and produce good results when laminated<br />

between wood skins: lightweight wood, such as<br />

balsa, in both flat and end-grain dimensi<strong>on</strong>s; various<br />

types of foam; and manufactured h<strong>on</strong>eycomb materials,<br />

especially resin-impregnated h<strong>on</strong>eycomb paper.<br />

Balsa is <strong>on</strong>e of the better core materials. When used in<br />

its end-grain dimensi<strong>on</strong>, it makes a core with excellent<br />

crush resistance. We’ve also tried balsa in flat grain, using<br />

it both as a core and to improve structural strength by<br />

c<strong>on</strong>tributing to the overall stiffness and strength of a<br />

panel. End-grain balsa is available with a special surface<br />

treatment that is designed to reduce resin absorpti<strong>on</strong><br />

into the core. It is also available in an untreated form.<br />

When using the untreated type, there is a possibility<br />

of epoxy starvati<strong>on</strong> to the glue joint of the layer glued<br />

over it. We have seen epoxy drain completely through 1 ⁄2"<br />

(12mm) thick end-grain balsa, so be sure to experiment<br />

with gluing technique if you are using the<br />

unsealed type.<br />

We have often used other lightweight woods in flat<br />

grain dimensi<strong>on</strong> as cores in some framework laminati<strong>on</strong>s.<br />

Laminated deck beams are good examples of<br />

how to save weight higher up in a hull by combining<br />

proper proporti<strong>on</strong>s of a low-density wood, say, cedar,<br />

with a high-density wood, Douglas fir or mahogany.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> resulting laminati<strong>on</strong> has adequate stiffness and<br />

strength and is much lighter than <strong>on</strong>e made entirely<br />

of high-density wood.<br />

Resin-impregnated h<strong>on</strong>eycomb paper is the cheapest<br />

of the various h<strong>on</strong>eycombs available, and it is easy to<br />

b<strong>on</strong>d and apply. Prices vary by cell size, resin c<strong>on</strong>tent,<br />

and thickness. We used paper h<strong>on</strong>eycomb for years<br />

and found its light weight and good crush and shear<br />

strengths perfectly adequate in many applicati<strong>on</strong>s.<br />

H<strong>on</strong>eycomb paper is helpful <strong>on</strong> both flat and curved<br />

surfaces. It can be applied to slightly compounded<br />

areas, such as decks and cabin tops, because its cells<br />

are able to bend slightly and deform. H<strong>on</strong>eycombs<br />

are available in a wide variety of materials, from paper<br />

to titanium. Metallic h<strong>on</strong>eycombs are am<strong>on</strong>g the most<br />

expensive core materials.<br />

Foam cores have become a reas<strong>on</strong>able alternative to<br />

balsa and h<strong>on</strong>eycombs. Foams cover a wide range in<br />

price and density, but they are generally more expensive<br />

than balsa and paper h<strong>on</strong>eycombs. <str<strong>on</strong>g>The</str<strong>on</strong>g>y are better<br />

insulators than other core materials. <strong>WEST</strong> <strong>SYSTEM</strong> epoxy<br />

will not chemically react in a destructive way with<br />

foams. But, because of the insulating properties of foam,