The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

108 Core <strong>Boat</strong>building Techniques<br />

Now remove excess stock to get close to the lines you<br />

have drawn. <str<strong>on</strong>g>The</str<strong>on</strong>g>re are many ways to do this: you can<br />

make a careful cut with a sharp handsaw, sawing as<br />

close to the marks as your skill will allow, or you can<br />

use a wide chisel and mallet, a large plane with a deepset<br />

blade, or a power plane. When you have rough<br />

machined the bevel close to its marks, use a sharp<br />

block plane to finish it, watching the marked lines as<br />

you proceed.<br />

At this point, place the stock <strong>on</strong> a flat surface such as a<br />

workbench with a block under the feather edge of the<br />

bevel which can support the edge but will not interfere<br />

with the hand planing. C<strong>on</strong>tinually check the bevel for<br />

flatness in both directi<strong>on</strong>s so that when you plane the<br />

bevel to its final marked lines, you leave a fine, feathered<br />

edge at the very end of the stock. When you have<br />

completed the scarf bevel, check to make sure that it is<br />

flat in both the length and widths planed—we just set<br />

the edge of the plane <strong>on</strong> the bevel surface for a quick<br />

check. This ensures a totally flat surface, which will<br />

mate properly with another scarf bevel to form a<br />

dimensi<strong>on</strong>ally accurate and str<strong>on</strong>g scarf joint.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> scarfing jig<br />

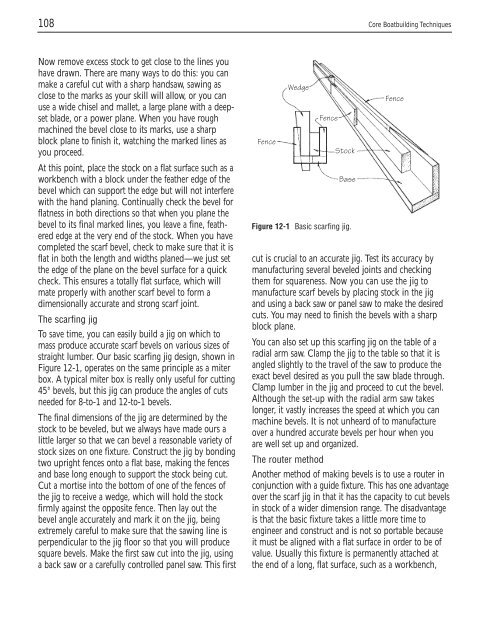

To save time, you can easily build a jig <strong>on</strong> which to<br />

mass produce accurate scarf bevels <strong>on</strong> various sizes of<br />

straight lumber. Our basic scarfing jig design, shown in<br />

Figure 12-1, operates <strong>on</strong> the same principle as a miter<br />

box. A typical miter box is really <strong>on</strong>ly useful for cutting<br />

45° bevels, but this jig can produce the angles of cuts<br />

needed for 8-to-1 and 12-to-1 bevels.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> final dimensi<strong>on</strong>s of the jig are determined by the<br />

stock to be beveled, but we always have made ours a<br />

little larger so that we can bevel a reas<strong>on</strong>able variety of<br />

stock sizes <strong>on</strong> <strong>on</strong>e fixture. C<strong>on</strong>struct the jig by b<strong>on</strong>ding<br />

two upright fences <strong>on</strong>to a flat base, making the fences<br />

and base l<strong>on</strong>g enough to support the stock being cut.<br />

Cut a mortise into the bottom of <strong>on</strong>e of the fences of<br />

the jig to receive a wedge, which will hold the stock<br />

firmly against the opposite fence. <str<strong>on</strong>g>The</str<strong>on</strong>g>n lay out the<br />

bevel angle accurately and mark it <strong>on</strong> the jig, being<br />

extremely careful to make sure that the sawing line is<br />

perpendicular to the jig floor so that you will produce<br />

square bevels. Make the first saw cut into the jig, using<br />

a back saw or a carefully c<strong>on</strong>trolled panel saw. This first<br />

Fence<br />

Wedge<br />

Fence<br />

Stock<br />

Base<br />

Figure 12-1 Basic scarfing jig.<br />

Fence<br />

cut is crucial to an accurate jig. Test its accuracy by<br />

manufacturing several beveled joints and checking<br />

them for squareness. Now you can use the jig to<br />

manufacture scarf bevels by placing stock in the jig<br />

and using a back saw or panel saw to make the desired<br />

cuts. You may need to finish the bevels with a sharp<br />

block plane.<br />

You can also set up this scarfing jig <strong>on</strong> the table of a<br />

radial arm saw. Clamp the jig to the table so that it is<br />

angled slightly to the travel of the saw to produce the<br />

exact bevel desired as you pull the saw blade through.<br />

Clamp lumber in the jig and proceed to cut the bevel.<br />

Although the set-up with the radial arm saw takes<br />

l<strong>on</strong>ger, it vastly increases the speed at which you can<br />

machine bevels. It is not unheard of to manufacture<br />

over a hundred accurate bevels per hour when you<br />

are well set up and organized.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> router method<br />

Another method of making bevels is to use a router in<br />

c<strong>on</strong>juncti<strong>on</strong> with a guide fixture. This has <strong>on</strong>e advantage<br />

over the scarf jig in that it has the capacity to cut bevels<br />

in stock of a wider dimensi<strong>on</strong> range. <str<strong>on</strong>g>The</str<strong>on</strong>g> disadvantage<br />

is that the basic fixture takes a little more time to<br />

engineer and c<strong>on</strong>struct and is not so portable because<br />

it must be aligned with a flat surface in order to be of<br />

value. Usually this fixture is permanently attached at<br />

the end of a l<strong>on</strong>g, flat surface, such as a workbench,