The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

116 Core <strong>Boat</strong>building Techniques<br />

Figure 12-13 Cutting scarf bevels <strong>on</strong> stacked panels.<br />

Clamping plywood scarf joints<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> potential problem with the plywood scarf joint is<br />

achieving proper clamping pressure. A large, flat work<br />

surface of the size used to fit the joint is required for<br />

clamping, but with <strong>on</strong>e additi<strong>on</strong>al provisi<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g> work<br />

surface must be of a material which will receive staples<br />

or small nails. If needed, you can positi<strong>on</strong> several sheets<br />

of 3 /4" (18mm) thick sheathing grade plywood over<br />

your floor or the workbench to receive fasteners readily.<br />

Cover that part of the work surface that will be beneath<br />

the scarf joint with wax paper or polyethylene sheet.<br />

Apply the b<strong>on</strong>ding adhesive, positi<strong>on</strong> the panels <strong>on</strong> the<br />

flat surface, and join the bevel surfaces together so that<br />

the surmarks line up. <str<strong>on</strong>g>The</str<strong>on</strong>g>n positi<strong>on</strong> a locating staple in<br />

each edge of the joint to prevent any movement of the<br />

two panels while you are clamping. Cover the top of<br />

the joint with wax paper and place a strip of plywood<br />

over the paper at the scarf joint. This plywood strip<br />

should be about the same thickness as the material<br />

being spliced together and should be wide enough to<br />

cover at least the entire area of the splice. Drive a sufficient<br />

number of staples or nails through the strip and<br />

the scarf joint into the receiving material below,<br />

drawing the two beveled surfaces firmly together.<br />

You can create adequate pressure with staples when<br />

clamping plywood up to 1 /4" (6mm) thick. With thicker<br />

panels, nailing is recommended. When using nails, we<br />

usually use a much thicker clamping strip, of perhaps<br />

3 /4" (18mm) stock, so that fewer nails are necessary for<br />

even pressure over the entire surface area. A piece of<br />

curved stock, held in place with clamps as shown in<br />

Figure 12-14, will help distribute clamping pressure<br />

evenly across your joint.<br />

Because you may be b<strong>on</strong>ding wide panels, it is<br />

extremely important to fair up these joints while the<br />

adhesive is still in its partial cure stage. Use the same<br />

tools and procedures to clean up and fair plywood scarf<br />

joints as you would use with lumber scarf joints. It<br />

works best to do the cleanup and fairing operati<strong>on</strong>s<br />

while the plywood is still lying <strong>on</strong> a flat surface; this is<br />

especially important with thinner plywood.<br />

Scarfing in Place<br />

Very often in a boatbuilding job, you may need a scarfed<br />

panel of very large dimensi<strong>on</strong>s (for example, a complete<br />

deck surface) which is impractical to install in <strong>on</strong>e piece.<br />

To solve this problem, we have developed a technique to<br />

scarf together plywood panels right in place <strong>on</strong> the hull<br />

as they are being installed. This scarfing-in-place procedure<br />

adds two difficulties in the basic plywood b<strong>on</strong>ding<br />

operati<strong>on</strong>s: (l) the measuring, marking, and fitting of the<br />

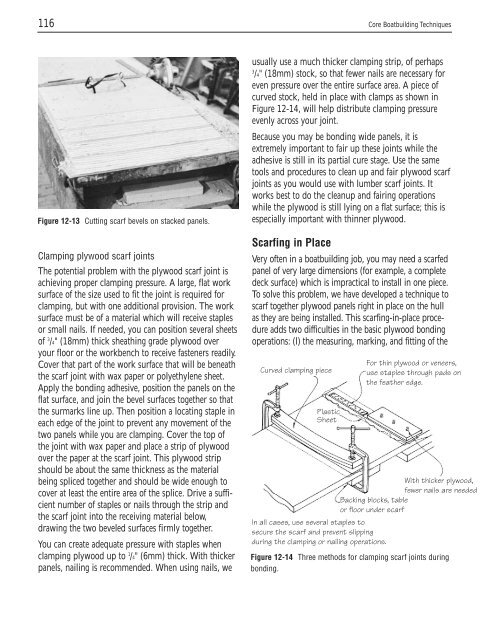

Curved clamping piece<br />

Plastic<br />

Sheet<br />

For thin plywood or veneers,<br />

use staples through pads <strong>on</strong><br />

the feather edge.<br />

With thicker plywood,<br />

fewer nails are needed<br />

Backing blocks, table<br />

or floor under scarf<br />

In all cases, use several staples to<br />

secure the scarf and prevent slipping<br />

during the clamping or nailing operati<strong>on</strong>s.<br />

Figure 12-14 Three methods for clamping scarf joints during<br />

b<strong>on</strong>ding.