The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 20 – Building a Mold or Plug 223<br />

Figure 20-2 A plug for a 32' (9.7m) catamaran is polished<br />

and waxed, ready for a mold to be cast. <str<strong>on</strong>g>The</str<strong>on</strong>g> mold for the<br />

upper surface will be female in the areas of the hulls and<br />

cabin top and male in the cockpit area.<br />

the planking easily. When making the mold frames,<br />

remember that you must not <strong>on</strong>ly deduct the planking<br />

thickness of the hull, but also the planking thickness<br />

that you will use <strong>on</strong> the mold. If the hull is to be<br />

1 3 ⁄2" (12mm) thick and the ribbands are to be ⁄4" (18mm)<br />

thick, you must deduct a total of 11 ⁄4" (30mm) planking<br />

thickness from the lofting in order to arrive at properly<br />

sized mold frames. Because of this unusually large<br />

deducti<strong>on</strong>, you must pay careful attenti<strong>on</strong> to the<br />

planking thickness deducti<strong>on</strong> procedure. (See<br />

Chapter 16 for a detailed discussi<strong>on</strong> of lofting.)<br />

Once you have properly set up the mold frames and<br />

completed final fairing, you can begin planking the<br />

mold. Although it is not always necessary, many<br />

molded hulls are built with provisi<strong>on</strong>s in the mold<br />

to insert a permanent keel and stem which can be<br />

removed with the hull from the mold. It is relatively<br />

easy to insert a permanent keel into the mold and to<br />

attach the veneers permanently to the keel during the<br />

molding process.<br />

If the keel is to be 4" (100mm) wide, leave a gap al<strong>on</strong>g<br />

the centerline of the mold slightly over this width,<br />

allowing approximately 1 ⁄8" (3mm) clearance between<br />

each side of the keel and the mold. We run a permanent<br />

ribband, which we call a keel runner, al<strong>on</strong>g each<br />

side of the keel. This then becomes a joining point for<br />

all the rest of the ribbands <strong>on</strong> the mold that would<br />

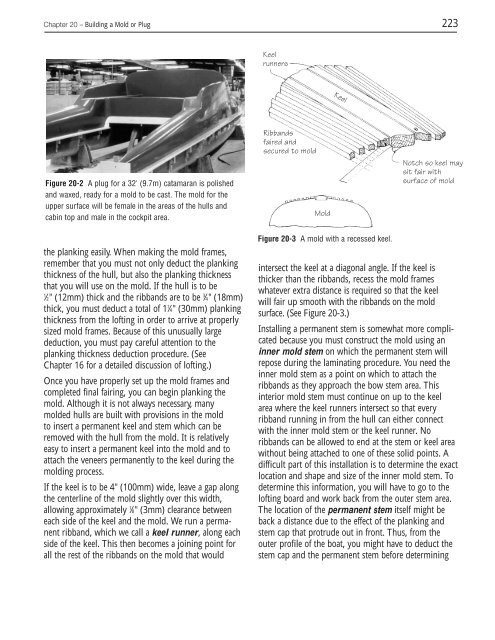

Keel<br />

runners<br />

Ribbands<br />

faired and<br />

secured to mold<br />

Mold<br />

Keel<br />

Figure 20-3 A mold with a recessed keel.<br />

Notch so keel may<br />

sit fair with<br />

surface of mold<br />

intersect the keel at a diag<strong>on</strong>al angle. If the keel is<br />

thicker than the ribbands, recess the mold frames<br />

whatever extra distance is required so that the keel<br />

will fair up smooth with the ribbands <strong>on</strong> the mold<br />

surface. (See Figure 20-3.)<br />

Installing a permanent stem is somewhat more complicated<br />

because you must c<strong>on</strong>struct the mold using an<br />

inner mold stem <strong>on</strong> which the permanent stem will<br />

repose during the laminating procedure. You need the<br />

inner mold stem as a point <strong>on</strong> which to attach the<br />

ribbands as they approach the bow stem area. This<br />

interior mold stem must c<strong>on</strong>tinue <strong>on</strong> up to the keel<br />

area where the keel runners intersect so that every<br />

ribband running in from the hull can either c<strong>on</strong>nect<br />

with the inner mold stem or the keel runner. No<br />

ribbands can be allowed to end at the stem or keel area<br />

without being attached to <strong>on</strong>e of these solid points. A<br />

difficult part of this installati<strong>on</strong> is to determine the exact<br />

locati<strong>on</strong> and shape and size of the inner mold stem. To<br />

determine this informati<strong>on</strong>, you will have to go to the<br />

lofting board and work back from the outer stem area.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> locati<strong>on</strong> of the permanent stem itself might be<br />

back a distance due to the effect of the planking and<br />

stem cap that protrude out in fr<strong>on</strong>t. Thus, from the<br />

outer profile of the boat, you might have to deduct the<br />

stem cap and the permanent stem before determining