The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

326 Later Producti<strong>on</strong> Steps<br />

Teak veneer<br />

Cap<br />

Plywood panels<br />

Teak fiddle rail<br />

Resin-impregnated<br />

h<strong>on</strong>eycomp paper<br />

Adhesive flow of the epoxy mixture forms<br />

fillets up the walls of the paper h<strong>on</strong>eycomb<br />

Figure 26-19 Secti<strong>on</strong>s through the countertop and cockpit<br />

sole showing core c<strong>on</strong>structi<strong>on</strong>.<br />

of the floor permanently to the hull has helped locate<br />

the floor as low as possible within the hull cavity. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

permanent floor also has great potential to c<strong>on</strong>tribute<br />

structurally to the overall strength and stiffness of the<br />

hull itself.<br />

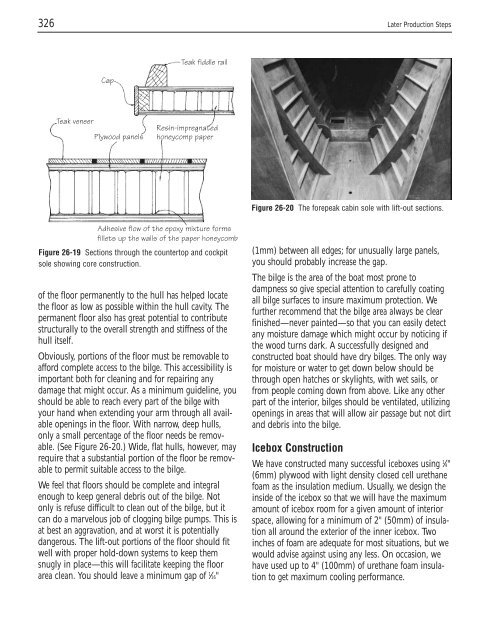

Obviously, porti<strong>on</strong>s of the floor must be removable to<br />

afford complete access to the bilge. This accessibility is<br />

important both for cleaning and for repairing any<br />

damage that might occur. As a minimum guideline, you<br />

should be able to reach every part of the bilge with<br />

your hand when extending your arm through all available<br />

openings in the floor. With narrow, deep hulls,<br />

<strong>on</strong>ly a small percentage of the floor needs be removable.<br />

(See Figure 26-20.) Wide, flat hulls, however, may<br />

require that a substantial porti<strong>on</strong> of the floor be removable<br />

to permit suitable access to the bilge.<br />

We feel that floors should be complete and integral<br />

enough to keep general debris out of the bilge. Not<br />

<strong>on</strong>ly is refuse difficult to clean out of the bilge, but it<br />

can do a marvelous job of clogging bilge pumps. This is<br />

at best an aggravati<strong>on</strong>, and at worst it is potentially<br />

dangerous. <str<strong>on</strong>g>The</str<strong>on</strong>g> lift-out porti<strong>on</strong>s of the floor should fit<br />

well with proper hold-down systems to keep them<br />

snugly in place—this will facilitate keeping the floor<br />

area clean. You should leave a minimum gap of 1 ⁄16"<br />

Figure 26-20 <str<strong>on</strong>g>The</str<strong>on</strong>g> forepeak cabin sole with lift-out secti<strong>on</strong>s.<br />

(1mm) between all edges; for unusually large panels,<br />

you should probably increase the gap.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> bilge is the area of the boat most pr<strong>on</strong>e to<br />

dampness so give special attenti<strong>on</strong> to carefully coating<br />

all bilge surfaces to insure maximum protecti<strong>on</strong>. We<br />

further recommend that the bilge area always be clear<br />

finished—never painted—so that you can easily detect<br />

any moisture damage which might occur by noticing if<br />

the wood turns dark. A successfully designed and<br />

c<strong>on</strong>structed boat should have dry bilges. <str<strong>on</strong>g>The</str<strong>on</strong>g> <strong>on</strong>ly way<br />

for moisture or water to get down below should be<br />

through open hatches or skylights, with wet sails, or<br />

from people coming down from above. Like any other<br />

part of the interior, bilges should be ventilated, utilizing<br />

openings in areas that will allow air passage but not dirt<br />

and debris into the bilge.<br />

Icebox C<strong>on</strong>structi<strong>on</strong><br />

We have c<strong>on</strong>structed many successful iceboxes using 1 ⁄4"<br />

(6mm) plywood with light density closed cell urethane<br />

foam as the insulati<strong>on</strong> medium. Usually, we design the<br />

inside of the icebox so that we will have the maximum<br />

amount of icebox room for a given amount of interior<br />

space, allowing for a minimum of 2" (50mm) of insulati<strong>on</strong><br />

all around the exterior of the inner icebox. Two<br />

inches of foam are adequate for most situati<strong>on</strong>s, but we<br />

would advise against using any less. On occasi<strong>on</strong>, we<br />

have used up to 4" (100mm) of urethane foam insulati<strong>on</strong><br />

to get maximum cooling performance.