The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8 Fundamentals of Wood/<strong>Epoxy</strong> Composite <strong>Boat</strong>building<br />

epoxy polymers are complex molecules of multidirecti<strong>on</strong>al,<br />

interlocking chains. <str<strong>on</strong>g>The</str<strong>on</strong>g>se chemical characteristics<br />

give the cured epoxy physical properties in its own<br />

right. In general, epoxies have greater strength, less<br />

shrinkage, better moisture resistance, better resistance<br />

to fatigue, and are less flammable than polyesters.<br />

Epoxies are also excellent b<strong>on</strong>ding agents for a wide<br />

variety of surfaces.<br />

<strong>WEST</strong> <strong>SYSTEM</strong> ® <strong>Epoxy</strong><br />

This book specifically recommends the use of <strong>WEST</strong><br />

<strong>SYSTEM</strong> epoxy in all manufacturing. While this may<br />

appear to be self-serving, the fact is that our instructi<strong>on</strong>s<br />

would be of little value if the b<strong>on</strong>ding and sealing<br />

materials, which are central to our method of boatbuilding,<br />

were not discussed in detail. <strong>WEST</strong> <strong>SYSTEM</strong><br />

epoxy is a versatile, high-quality, two-part epoxy that<br />

is easily modified for a wide range of coating and<br />

adhesive applicati<strong>on</strong>s. It is used for c<strong>on</strong>structi<strong>on</strong> and<br />

repairs requiring superior moisture resistance and high<br />

strength. It b<strong>on</strong>ds to fiberglass, wood, metal, fabrics,<br />

and other composite materials, and is especially suited<br />

for marine applicati<strong>on</strong>s.<br />

<strong>Epoxy</strong> brands can vary widely in their formulati<strong>on</strong>s,<br />

quality of raw materials, and suitability for marine<br />

envir<strong>on</strong>ments. It’s easy to market an off-the-shelf industrial<br />

epoxy product as a marine epoxy or formulate an<br />

epoxy with <strong>on</strong>e or two favorable characteristics while<br />

sacrificing other important characteristics. It’s much<br />

more difficult balancing all of the physical and mechanical<br />

properties necessary for a versatile, high-quality<br />

marine epoxy. Defining an epoxy’s performance criteria<br />

and designing a formula to meet those criteria require<br />

good chemistry, rigorous test programs, skillful shop<br />

work, and direct experience with high-performance<br />

boats and other composite structures.<br />

Since 1972, <str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Brothers</str<strong>on</strong>g>, Inc. has tested potential<br />

resin and hardener formulas, ingredients, and combinati<strong>on</strong>s<br />

to compare fatigue strength, compressi<strong>on</strong> strength,<br />

glass transiti<strong>on</strong> temperature, and peak exotherm. Additi<strong>on</strong>ally,<br />

our materials test lab tests qualified samples for<br />

hardness, tensile strength, tensile el<strong>on</strong>gati<strong>on</strong>, tensile<br />

modulus, flexural strength, flexural modulus, heat<br />

deflecti<strong>on</strong> temperature, impact resistance, and moisture<br />

exclusi<strong>on</strong> effectiveness.<br />

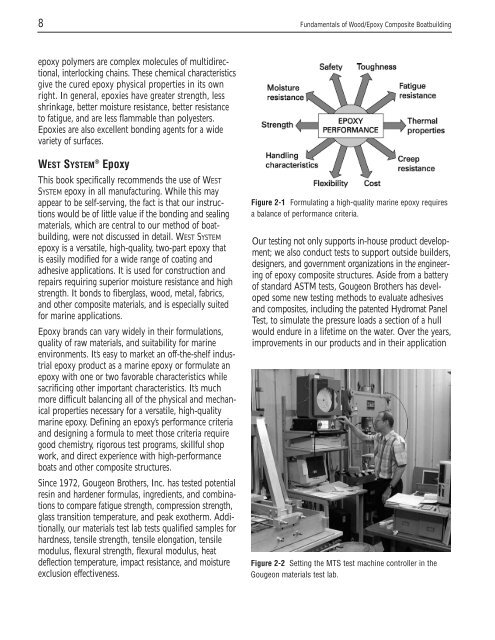

Figure 2-1 Formulating a high-quality marine epoxy requires<br />

a balance of performance criteria.<br />

Our testing not <strong>on</strong>ly supports in-house product development;<br />

we also c<strong>on</strong>duct tests to support outside builders,<br />

designers, and government organizati<strong>on</strong>s in the engineering<br />

of epoxy composite structures. Aside from a battery<br />

of standard ASTM tests, <str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Brothers</str<strong>on</strong>g> has developed<br />

some new testing methods to evaluate adhesives<br />

and composites, including the patented Hydromat Panel<br />

Test, to simulate the pressure loads a secti<strong>on</strong> of a hull<br />

would endure in a lifetime <strong>on</strong> the water. Over the years,<br />

improvements in our products and in their applicati<strong>on</strong><br />

Figure 2-2 Setting the MTS test machine c<strong>on</strong>troller in the<br />

<str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> materials test lab.