The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 12 – Scarfing 111<br />

Producti<strong>on</strong> b<strong>on</strong>ding needs to be well organized and<br />

requires the cooperati<strong>on</strong> of at least two people. First,<br />

pre-sort the stock to be joined and lay out the individual<br />

pieces <strong>on</strong> a flat surface opposite <strong>on</strong>e another with each<br />

of the beveled surfaces facing up and pointing toward<br />

its mate. No doubt you will want to make up varying<br />

lengths of scarfed material, and you should do your<br />

planning at this stage to minimize waste when you are<br />

actually assembling the scarfed stock <strong>on</strong> the boat.<br />

When you have laid out and organized all of the stock,<br />

establish a separate assembly area close by <strong>on</strong> a flat<br />

surface and prepare the clamps and a staple gun which<br />

shoots 3�8" (9mm) wide-crown staples. On the floor, lay<br />

out wax paper or a polyethylene sheet that is somewhat<br />

wider than the scarf joints themselves to prevent<br />

inadvertent b<strong>on</strong>ding. Make up the adhesive mixture<br />

and apply it to all the upward-facing beveled surfaces,<br />

following the applicati<strong>on</strong> procedure previously described.<br />

Move two matched pieces of stock to the prepared<br />

assembly area and align their beveled b<strong>on</strong>ding surfaces,<br />

using the procedure previously described. After you<br />

have inserted the locating staples, turn the stock up <strong>on</strong><br />

edge with the side of the scarf joint resting <strong>on</strong> the wax<br />

paper or polyethylene sheet. Before you move another<br />

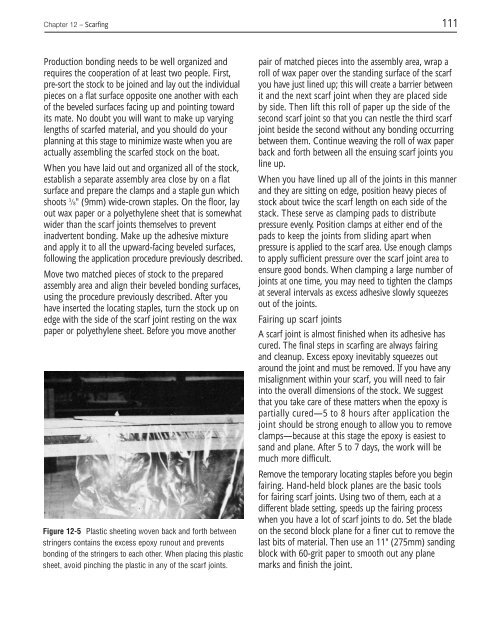

Figure 12-5 Plastic sheeting woven back and forth between<br />

stringers c<strong>on</strong>tains the excess epoxy runout and prevents<br />

b<strong>on</strong>ding of the stringers to each other. When placing this plastic<br />

sheet, avoid pinching the plastic in any of the scarf joints.<br />

pair of matched pieces into the assembly area, wrap a<br />

roll of wax paper over the standing surface of the scarf<br />

you have just lined up; this will create a barrier between<br />

it and the next scarf joint when they are placed side<br />

by side. <str<strong>on</strong>g>The</str<strong>on</strong>g>n lift this roll of paper up the side of the<br />

sec<strong>on</strong>d scarf joint so that you can nestle the third scarf<br />

joint beside the sec<strong>on</strong>d without any b<strong>on</strong>ding occurring<br />

between them. C<strong>on</strong>tinue weaving the roll of wax paper<br />

back and forth between all the ensuing scarf joints you<br />

line up.<br />

When you have lined up all of the joints in this manner<br />

and they are sitting <strong>on</strong> edge, positi<strong>on</strong> heavy pieces of<br />

stock about twice the scarf length <strong>on</strong> each side of the<br />

stack. <str<strong>on</strong>g>The</str<strong>on</strong>g>se serve as clamping pads to distribute<br />

pressure evenly. Positi<strong>on</strong> clamps at either end of the<br />

pads to keep the joints from sliding apart when<br />

pressure is applied to the scarf area. Use enough clamps<br />

to apply sufficient pressure over the scarf joint area to<br />

ensure good b<strong>on</strong>ds. When clamping a large number of<br />

joints at <strong>on</strong>e time, you may need to tighten the clamps<br />

at several intervals as excess adhesive slowly squeezes<br />

out of the joints.<br />

Fairing up scarf joints<br />

A scarf joint is almost finished when its adhesive has<br />

cured. <str<strong>on</strong>g>The</str<strong>on</strong>g> final steps in scarfing are always fairing<br />

and cleanup. Excess epoxy inevitably squeezes out<br />

around the joint and must be removed. If you have any<br />

misalignment within your scarf, you will need to fair<br />

into the overall dimensi<strong>on</strong>s of the stock. We suggest<br />

that you take care of these matters when the epoxy is<br />

partially cured—5 to 8 hours after applicati<strong>on</strong> the<br />

joint should be str<strong>on</strong>g enough to allow you to remove<br />

clamps—because at this stage the epoxy is easiest to<br />

sand and plane. After 5 to 7 days, the work will be<br />

much more difficult.<br />

Remove the temporary locating staples before you begin<br />

fairing. Hand-held block planes are the basic tools<br />

for fairing scarf joints. Using two of them, each at a<br />

different blade setting, speeds up the fairing process<br />

when you have a lot of scarf joints to do. Set the blade<br />

<strong>on</strong> the sec<strong>on</strong>d block plane for a finer cut to remove the<br />

last bits of material. <str<strong>on</strong>g>The</str<strong>on</strong>g>n use an 11" (275mm) sanding<br />

block with 60-grit paper to smooth out any plane<br />

marks and finish the joint.