The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 23 – Strip Plank Laminated Veneer and Strip Composite C<strong>on</strong>structi<strong>on</strong> 273<br />

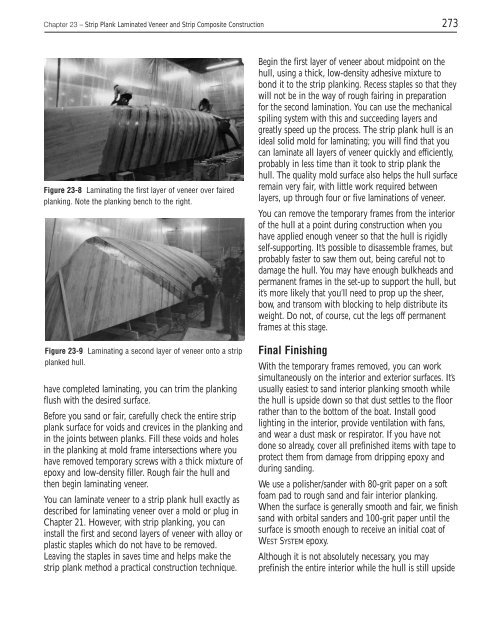

Figure 23-8 Laminating the first layer of veneer over faired<br />

planking. Note the planking bench to the right.<br />

Figure 23-9 Laminating a sec<strong>on</strong>d layer of veneer <strong>on</strong>to a strip<br />

planked hull.<br />

have completed laminating, you can trim the planking<br />

flush with the desired surface.<br />

Before you sand or fair, carefully check the entire strip<br />

plank surface for voids and crevices in the planking and<br />

in the joints between planks. Fill these voids and holes<br />

in the planking at mold frame intersecti<strong>on</strong>s where you<br />

have removed temporary screws with a thick mixture of<br />

epoxy and low-density filler. Rough fair the hull and<br />

then begin laminating veneer.<br />

You can laminate veneer to a strip plank hull exactly as<br />

described for laminating veneer over a mold or plug in<br />

Chapter 21. However, with strip planking, you can<br />

install the first and sec<strong>on</strong>d layers of veneer with alloy or<br />

plastic staples which do not have to be removed.<br />

Leaving the staples in saves time and helps make the<br />

strip plank method a practical c<strong>on</strong>structi<strong>on</strong> technique.<br />

Begin the first layer of veneer about midpoint <strong>on</strong> the<br />

hull, using a thick, low-density adhesive mixture to<br />

b<strong>on</strong>d it to the strip planking. Recess staples so that they<br />

will not be in the way of rough fairing in preparati<strong>on</strong><br />

for the sec<strong>on</strong>d laminati<strong>on</strong>. You can use the mechanical<br />

spiling system with this and succeeding layers and<br />

greatly speed up the process. <str<strong>on</strong>g>The</str<strong>on</strong>g> strip plank hull is an<br />

ideal solid mold for laminating; you will find that you<br />

can laminate all layers of veneer quickly and efficiently,<br />

probably in less time than it took to strip plank the<br />

hull. <str<strong>on</strong>g>The</str<strong>on</strong>g> quality mold surface also helps the hull surface<br />

remain very fair, with little work required between<br />

layers, up through four or five laminati<strong>on</strong>s of veneer.<br />

You can remove the temporary frames from the interior<br />

of the hull at a point during c<strong>on</strong>structi<strong>on</strong> when you<br />

have applied enough veneer so that the hull is rigidly<br />

self-supporting. It’s possible to disassemble frames, but<br />

probably faster to saw them out, being careful not to<br />

damage the hull. You may have enough bulkheads and<br />

permanent frames in the set-up to support the hull, but<br />

it’s more likely that you’ll need to prop up the sheer,<br />

bow, and transom with blocking to help distribute its<br />

weight. Do not, of course, cut the legs off permanent<br />

frames at this stage.<br />

Final Finishing<br />

With the temporary frames removed, you can work<br />

simultaneously <strong>on</strong> the interior and exterior surfaces. It’s<br />

usually easiest to sand interior planking smooth while<br />

the hull is upside down so that dust settles to the floor<br />

rather than to the bottom of the boat. Install good<br />

lighting in the interior, provide ventilati<strong>on</strong> with fans,<br />

and wear a dust mask or respirator. If you have not<br />

d<strong>on</strong>e so already, cover all prefinished items with tape to<br />

protect them from damage from dripping epoxy and<br />

during sanding.<br />

We use a polisher/sander with 80-grit paper <strong>on</strong> a soft<br />

foam pad to rough sand and fair interior planking.<br />

When the surface is generally smooth and fair, we finish<br />

sand with orbital sanders and 100-grit paper until the<br />

surface is smooth enough to receive an initial coat of<br />

<strong>WEST</strong> <strong>SYSTEM</strong> epoxy.<br />

Although it is not absolutely necessary, you may<br />

prefinish the entire interior while the hull is still upside