The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 19 – Keels, Stems, and Sheer Clamps 209<br />

therefore are usually more desirable, but they usually<br />

have to get thicker to get wider. When trying to develop<br />

sufficient b<strong>on</strong>ding area at various stati<strong>on</strong> positi<strong>on</strong>s, you<br />

will find that the flatter areas in the middle of the hull<br />

permit the use of a thinner keel secti<strong>on</strong>, while the finer<br />

bow area will require a much thicker keel secti<strong>on</strong> to<br />

provide the same b<strong>on</strong>ding area. Stems may have to be<br />

two or three times thicker than keels because the sharpness<br />

with which the planking joins the hull at the stem<br />

limits b<strong>on</strong>dable area.<br />

When you have developed the keel shape at a few<br />

stati<strong>on</strong>s, you can loft and fair the keel at all of the<br />

stati<strong>on</strong>s <strong>on</strong> the lofting board. It is important to<br />

remember that you need to subtract the cap thickness<br />

from the outside lofted profile of the hull in order to<br />

define the keel and stem profile. <str<strong>on</strong>g>The</str<strong>on</strong>g> stem is sometimes<br />

difficult to project properly in the lofting. See Chapter<br />

16 for a detailed discussi<strong>on</strong> of this procedure. Chapter<br />

16 also gives instructi<strong>on</strong>s for the development of all<br />

stem dimensi<strong>on</strong>s.<br />

Also lay out the area, usually near the forefoot, where<br />

the keel and stem meet. A 10- or 12-to-1 scarf bevel is<br />

needed for adequate strength, so the joint may be quite<br />

l<strong>on</strong>g. Because its two parts may curve slightly, a<br />

keel/stem scarf joint can be difficult to manufacture.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are no hard and fast rules about the directi<strong>on</strong>—<br />

stem over keel or keel over stem—the scarf should run.<br />

After lofting the stem and keel, locate the scarf. <str<strong>on</strong>g>The</str<strong>on</strong>g>n<br />

draw in the bearding line, which shows the inside<br />

intersecti<strong>on</strong> of the planking and the stem or keel. Make<br />

a pattern or template of the area where the stem and<br />

forward end of the keel join. <str<strong>on</strong>g>The</str<strong>on</strong>g> easiest way to do this<br />

is to use the nail method of transferring lines described<br />

in Chapter 17. It’s best to pick up all pertinent profile,<br />

sheer, scarf, stati<strong>on</strong>, and bearding lines at the same<br />

time. Check all measurements and label all lines clearly.<br />

Cut out the template and carefully trim it to the profile<br />

shape <strong>on</strong> the lofting.<br />

If you are planning to build your boat using the mold<br />

method for laminating hulls, the process of installing<br />

a permanent stem in your mold may involve a few<br />

extra steps. An inner mold stem may be necessary. Loft<br />

and shape this piece before you begin work <strong>on</strong> your<br />

keel/stem unit, following instructi<strong>on</strong>s in Chapter 20.<br />

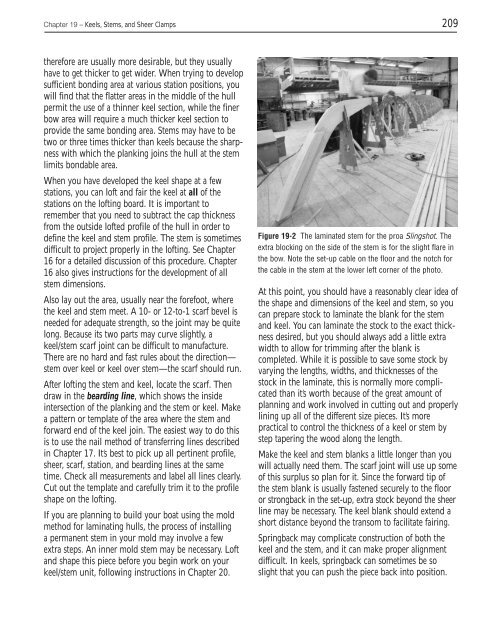

Figure 19-2 <str<strong>on</strong>g>The</str<strong>on</strong>g> laminated stem for the proa Slingshot. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

extra blocking <strong>on</strong> the side of the stem is for the slight flare in<br />

the bow. Note the set-up cable <strong>on</strong> the floor and the notch for<br />

the cable in the stem at the lower left corner of the photo.<br />

At this point, you should have a reas<strong>on</strong>ably clear idea of<br />

the shape and dimensi<strong>on</strong>s of the keel and stem, so you<br />

can prepare stock to laminate the blank for the stem<br />

and keel. You can laminate the stock to the exact thickness<br />

desired, but you should always add a little extra<br />

width to allow for trimming after the blank is<br />

completed. While it is possible to save some stock by<br />

varying the lengths, widths, and thicknesses of the<br />

stock in the laminate, this is normally more complicated<br />

than it’s worth because of the great amount of<br />

planning and work involved in cutting out and properly<br />

lining up all of the different size pieces. It’s more<br />

practical to c<strong>on</strong>trol the thickness of a keel or stem by<br />

step tapering the wood al<strong>on</strong>g the length.<br />

Make the keel and stem blanks a little l<strong>on</strong>ger than you<br />

will actually need them. <str<strong>on</strong>g>The</str<strong>on</strong>g> scarf joint will use up some<br />

of this surplus so plan for it. Since the forward tip of<br />

the stem blank is usually fastened securely to the floor<br />

or str<strong>on</strong>gback in the set-up, extra stock bey<strong>on</strong>d the sheer<br />

line may be necessary. <str<strong>on</strong>g>The</str<strong>on</strong>g> keel blank should extend a<br />

short distance bey<strong>on</strong>d the transom to facilitate fairing.<br />

Springback may complicate c<strong>on</strong>structi<strong>on</strong> of both the<br />

keel and the stem, and it can make proper alignment<br />

difficult. In keels, springback can sometimes be so<br />

slight that you can push the piece back into positi<strong>on</strong>.