The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 25 – Compounded Plywood C<strong>on</strong>structi<strong>on</strong> 299<br />

width of the keel joint, the width of the glass tape influences<br />

the shape of the folded hull. Wider glass cloth<br />

adds stiffness to the plywood, and this keeps it from<br />

bending as much as it would if it were not covered with<br />

glass. As a result, the hull is fuller al<strong>on</strong>g the keel line<br />

and more compounding is demanded of the panels.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are at least two ways to apply the fiberglass tape.<br />

You can install it dry, pressing it into the partially cured<br />

keel and then wetting it out with a stiff brush and<br />

unthickened epoxy, but this can be a lengthy operati<strong>on</strong><br />

because of the awkward working posture. Since it’s<br />

difficult to maneuver a squeegee from this angle, the<br />

dry method may also result in a little extra weight, and<br />

you might want to avoid this <strong>on</strong> a small boat. It’s much<br />

more c<strong>on</strong>venient to wet out a measured length of glass<br />

tape <strong>on</strong> a board which has been wrapped in plastic,<br />

remove excess epoxy with a plastic spreader, and then<br />

roll up the tape. Transfer it to the keel, unroll it in<br />

positi<strong>on</strong>, and smooth it out. Applying glass tape in the<br />

bow and other c<strong>on</strong>fined areas can be troublesome, so<br />

use the wet method in these spots.<br />

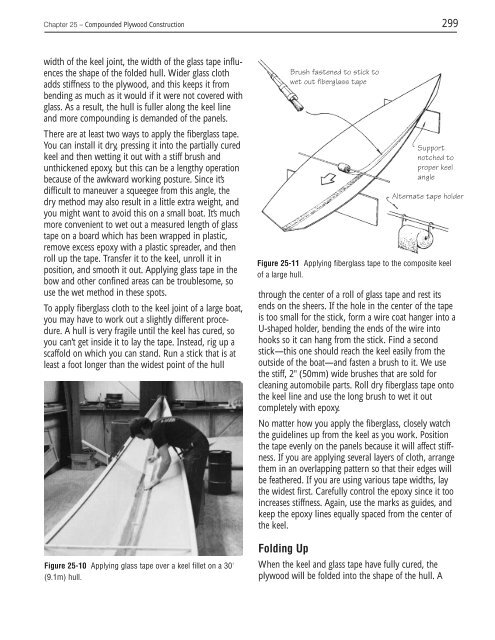

To apply fiberglass cloth to the keel joint of a large boat,<br />

you may have to work out a slightly different procedure.<br />

A hull is very fragile until the keel has cured, so<br />

you can’t get inside it to lay the tape. Instead, rig up a<br />

scaffold <strong>on</strong> which you can stand. Run a stick that is at<br />

least a foot l<strong>on</strong>ger than the widest point of the hull<br />

Figure 25-10 Applying glass tape over a keel fillet <strong>on</strong> a 30'<br />

(9.1m) hull.<br />

Brush fastened to stick to<br />

wet out fiberglass tape<br />

Support<br />

notched to<br />

proper keel<br />

angle<br />

Alternate tape holder<br />

Figure 25-11 Applying fiberglass tape to the composite keel<br />

of a large hull.<br />

through the center of a roll of glass tape and rest its<br />

ends <strong>on</strong> the sheers. If the hole in the center of the tape<br />

is too small for the stick, form a wire coat hanger into a<br />

U-shaped holder, bending the ends of the wire into<br />

hooks so it can hang from the stick. Find a sec<strong>on</strong>d<br />

stick—this <strong>on</strong>e should reach the keel easily from the<br />

outside of the boat—and fasten a brush to it. We use<br />

the stiff, 2" (50mm) wide brushes that are sold for<br />

cleaning automobile parts. Roll dry fiberglass tape <strong>on</strong>to<br />

the keel line and use the l<strong>on</strong>g brush to wet it out<br />

completely with epoxy.<br />

No matter how you apply the fiberglass, closely watch<br />

the guidelines up from the keel as you work. Positi<strong>on</strong><br />

the tape evenly <strong>on</strong> the panels because it will affect stiffness.<br />

If you are applying several layers of cloth, arrange<br />

them in an overlapping pattern so that their edges will<br />

be feathered. If you are using various tape widths, lay<br />

the widest first. Carefully c<strong>on</strong>trol the epoxy since it too<br />

increases stiffness. Again, use the marks as guides, and<br />

keep the epoxy lines equally spaced from the center of<br />

the keel.<br />

Folding Up<br />

When the keel and glass tape have fully cured, the<br />

plywood will be folded into the shape of the hull. A