The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 21 – Laminating Veneer Over a Mold or Plug 233<br />

Figure 21-5 More staples are necessary to hold down thin<br />

veneers in a reverse or c<strong>on</strong>cave area near a skeg. Note the<br />

reas<strong>on</strong>ably regular stapling patterns employed <strong>on</strong> planking in<br />

the foreground.<br />

members such as the stem and keel, although these<br />

may be left in place if corrosi<strong>on</strong>-resistant types are used.<br />

From the third layer <strong>on</strong>, we use shorter staples, say 3 ⁄8"<br />

(9mm) or 5 ⁄16" (8mm) l<strong>on</strong>g for three layers of 1 ⁄8" (3mm)<br />

veneer, because we are no l<strong>on</strong>ger stapling into the<br />

mold. Since these staples will not penetrate bey<strong>on</strong>d the<br />

first layer and will not interfere with the mold, they do<br />

not have to be extracted. We do, however, pull out<br />

staples used <strong>on</strong> the final, exterior laminati<strong>on</strong>.<br />

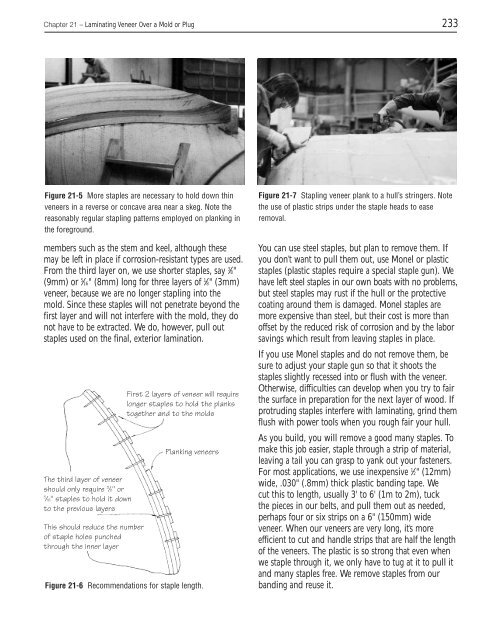

<str<strong>on</strong>g>The</str<strong>on</strong>g> third layer of veneer<br />

should <strong>on</strong>ly require 3 ⁄8" or<br />

5 ⁄16" staples to hold it down<br />

to the previous layers<br />

This should reduce the number<br />

of staple holes punched<br />

through the inner layer<br />

First 2 layers of veneer will require<br />

l<strong>on</strong>ger staples to hold the planks<br />

together and to the molds<br />

Planking veneers<br />

Figure 21-6 Recommendati<strong>on</strong>s for staple length.<br />

Figure 21-7 Stapling veneer plank to a hull’s stringers. Note<br />

the use of plastic strips under the staple heads to ease<br />

removal.<br />

You can use steel staples, but plan to remove them. If<br />

you d<strong>on</strong>’t want to pull them out, use M<strong>on</strong>el or plastic<br />

staples (plastic staples require a special staple gun). We<br />

have left steel staples in our own boats with no problems,<br />

but steel staples may rust if the hull or the protective<br />

coating around them is damaged. M<strong>on</strong>el staples are<br />

more expensive than steel, but their cost is more than<br />

offset by the reduced risk of corrosi<strong>on</strong> and by the labor<br />

savings which result from leaving staples in place.<br />

If you use M<strong>on</strong>el staples and do not remove them, be<br />

sure to adjust your staple gun so that it shoots the<br />

staples slightly recessed into or flush with the veneer.<br />

Otherwise, difficulties can develop when you try to fair<br />

the surface in preparati<strong>on</strong> for the next layer of wood. If<br />

protruding staples interfere with laminating, grind them<br />

flush with power tools when you rough fair your hull.<br />

As you build, you will remove a good many staples. To<br />

make this job easier, staple through a strip of material,<br />

leaving a tail you can grasp to yank out your fasteners.<br />

For most applicati<strong>on</strong>s, we use inexpensive 1 ⁄2" (12mm)<br />

wide, .030" (.8mm) thick plastic banding tape. We<br />

cut this to length, usually 3' to 6' (1m to 2m), tuck<br />

the pieces in our belts, and pull them out as needed,<br />

perhaps four or six strips <strong>on</strong> a 6" (150mm) wide<br />

veneer. When our veneers are very l<strong>on</strong>g, it’s more<br />

efficient to cut and handle strips that are half the length<br />

of the veneers. <str<strong>on</strong>g>The</str<strong>on</strong>g> plastic is so str<strong>on</strong>g that even when<br />

we staple through it, we <strong>on</strong>ly have to tug at it to pull it<br />

and many staples free. We remove staples from our<br />

banding and reuse it.