The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

296 Hull C<strong>on</strong>structi<strong>on</strong> Methods<br />

2" wide nyl<strong>on</strong> webbing<br />

b<strong>on</strong>ded with epoxy<br />

and colloidal silica mixture<br />

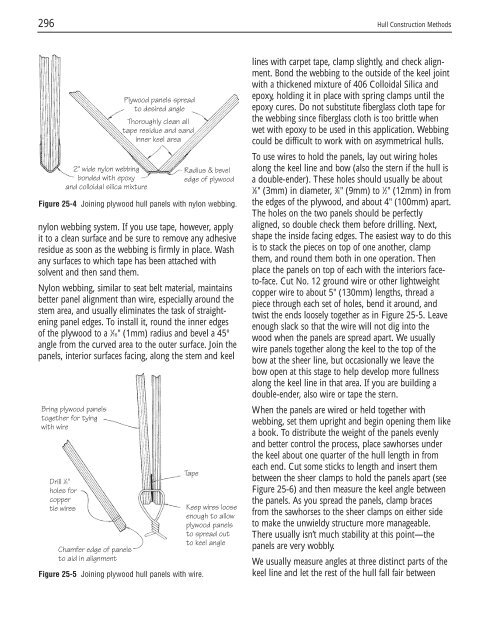

Figure 25-4 Joining plywood hull panels with nyl<strong>on</strong> webbing.<br />

nyl<strong>on</strong> webbing system. If you use tape, however, apply<br />

it to a clean surface and be sure to remove any adhesive<br />

residue as so<strong>on</strong> as the webbing is firmly in place. Wash<br />

any surfaces to which tape has been attached with<br />

solvent and then sand them.<br />

Nyl<strong>on</strong> webbing, similar to seat belt material, maintains<br />

better panel alignment than wire, especially around the<br />

stem area, and usually eliminates the task of straightening<br />

panel edges. To install it, round the inner edges<br />

of the plywood to a 1 ⁄16" (1mm) radius and bevel a 45°<br />

angle from the curved area to the outer surface. Join the<br />

panels, interior surfaces facing, al<strong>on</strong>g the stem and keel<br />

Bring plywood panels<br />

together for tying<br />

with wire<br />

Drill 1 ⁄8"<br />

holes for<br />

copper<br />

tie wires<br />

Chamfer edge of panels<br />

to aid in alignment<br />

Plywood panels spread<br />

to desired angle<br />

Thoroughly clean all<br />

tape residue and sand<br />

inner keel area<br />

Tape<br />

Figure 25-5 Joining plywood hull panels with wire.<br />

Radius & bevel<br />

edge of plywood<br />

Keep wires loose<br />

enough to allow<br />

plywood panels<br />

to spread out<br />

to keel angle<br />

lines with carpet tape, clamp slightly, and check alignment.<br />

B<strong>on</strong>d the webbing to the outside of the keel joint<br />

with a thickened mixture of 406 Colloidal Silica and<br />

epoxy, holding it in place with spring clamps until the<br />

epoxy cures. Do not substitute fiberglass cloth tape for<br />

the webbing since fiberglass cloth is too brittle when<br />

wet with epoxy to be used in this applicati<strong>on</strong>. Webbing<br />

could be difficult to work with <strong>on</strong> asymmetrical hulls.<br />

To use wires to hold the panels, lay out wiring holes<br />

al<strong>on</strong>g the keel line and bow (also the stern if the hull is<br />

a double-ender). <str<strong>on</strong>g>The</str<strong>on</strong>g>se holes should usually be about<br />

1 3 1 ⁄8" (3mm) in diameter, ⁄8" (9mm) to ⁄2" (12mm) in from<br />

the edges of the plywood, and about 4" (100mm) apart.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> holes <strong>on</strong> the two panels should be perfectly<br />

aligned, so double check them before drilling. Next,<br />

shape the inside facing edges. <str<strong>on</strong>g>The</str<strong>on</strong>g> easiest way to do this<br />

is to stack the pieces <strong>on</strong> top of <strong>on</strong>e another, clamp<br />

them, and round them both in <strong>on</strong>e operati<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g>n<br />

place the panels <strong>on</strong> top of each with the interiors faceto-face.<br />

Cut No. 12 ground wire or other lightweight<br />

copper wire to about 5" (130mm) lengths, thread a<br />

piece through each set of holes, bend it around, and<br />

twist the ends loosely together as in Figure 25-5. Leave<br />

enough slack so that the wire will not dig into the<br />

wood when the panels are spread apart. We usually<br />

wire panels together al<strong>on</strong>g the keel to the top of the<br />

bow at the sheer line, but occasi<strong>on</strong>ally we leave the<br />

bow open at this stage to help develop more fullness<br />

al<strong>on</strong>g the keel line in that area. If you are building a<br />

double-ender, also wire or tape the stern.<br />

When the panels are wired or held together with<br />

webbing, set them upright and begin opening them like<br />

a book. To distribute the weight of the panels evenly<br />

and better c<strong>on</strong>trol the process, place sawhorses under<br />

the keel about <strong>on</strong>e quarter of the hull length in from<br />

each end. Cut some sticks to length and insert them<br />

between the sheer clamps to hold the panels apart (see<br />

Figure 25-6) and then measure the keel angle between<br />

the panels. As you spread the panels, clamp braces<br />

from the sawhorses to the sheer clamps <strong>on</strong> either side<br />

to make the unwieldy structure more manageable.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re usually isn’t much stability at this point—the<br />

panels are very wobbly.<br />

We usually measure angles at three distinct parts of the<br />

keel line and let the rest of the hull fall fair between