The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 11 – Laminating and B<strong>on</strong>ding Techniques 105<br />

make good applicators, but they require time-c<strong>on</strong>suming<br />

loading and cleaning. While it may seem to be efficient<br />

to use your finger to apply and smooth fillets, d<strong>on</strong>’t do<br />

it. A splinter in the joint may cut through your glove<br />

and into your finger, and this can be quite painful.<br />

To finish your joint, take a piece of thin stock a little<br />

wider than the fillet itself and round off <strong>on</strong>e end. Cut<br />

the radius of this curve to match the desired radius<br />

of your fillet when the stick is held so that it bisects<br />

the joint. Because this dimensi<strong>on</strong> is very important in<br />

c<strong>on</strong>trolling fillet size, round off several sticks and experiment<br />

with them. <str<strong>on</strong>g>The</str<strong>on</strong>g> rounded end of an 804 Mixing<br />

Stick creates a 3 ⁄8" (9mm) radius fillet. With a fillet stick<br />

of any given radius, you can further c<strong>on</strong>trol fillet size by<br />

changing the angle of your passes. When you hold the<br />

stick at a 10° angle to your joint, your fillet will be<br />

flatter, while if you hold it at a larger angle, it will be<br />

curved.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> experienced applicator can form a perfect fillet with<br />

<strong>on</strong>ly <strong>on</strong>e pass of the fillet stick over a properly applied<br />

fillet mixture. It is not unusual, however, to need several<br />

passes to form and smooth the fillet to the desired state.<br />

Always make the final pass with the fillet stick with some<br />

firmness so that the excess fillet mixture will be deposited<br />

<strong>on</strong> either side of the fillet. <str<strong>on</strong>g>The</str<strong>on</strong>g> pressure <strong>on</strong> the fillet stick<br />

is important because it creates a gap between the excess<br />

material and the fillet so that you can clean away the<br />

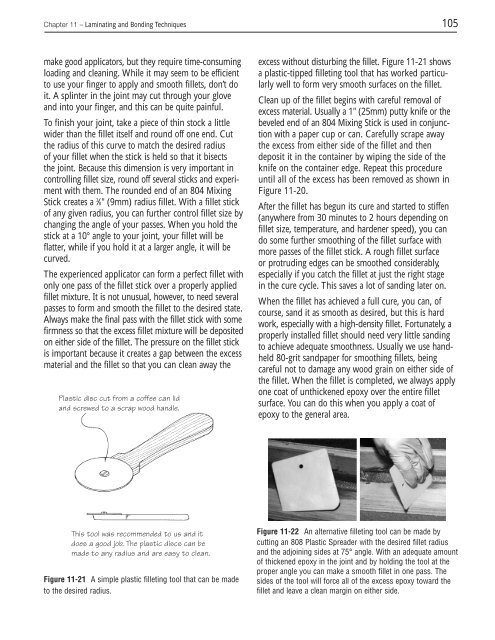

Plastic disc cut from a coffee can lid<br />

and screwed to a scrap wood handle.<br />

This tool was recommended to us and it<br />

does a good job. <str<strong>on</strong>g>The</str<strong>on</strong>g> plastic discs can be<br />

made to any radius and are easy to clean.<br />

Figure 11-21 A simple plastic filleting tool that can be made<br />

to the desired radius.<br />

excess without disturbing the fillet. Figure 11-21 shows<br />

a plastic-tipped filleting tool that has worked particularly<br />

well to form very smooth surfaces <strong>on</strong> the fillet.<br />

Clean up of the fillet begins with careful removal of<br />

excess material. Usually a 1" (25mm) putty knife or the<br />

beveled end of an 804 Mixing Stick is used in c<strong>on</strong>juncti<strong>on</strong><br />

with a paper cup or can. Carefully scrape away<br />

the excess from either side of the fillet and then<br />

deposit it in the c<strong>on</strong>tainer by wiping the side of the<br />

knife <strong>on</strong> the c<strong>on</strong>tainer edge. Repeat this procedure<br />

until all of the excess has been removed as shown in<br />

Figure 11-20.<br />

After the fillet has begun its cure and started to stiffen<br />

(anywhere from 30 minutes to 2 hours depending <strong>on</strong><br />

fillet size, temperature, and hardener speed), you can<br />

do some further smoothing of the fillet surface with<br />

more passes of the fillet stick. A rough fillet surface<br />

or protruding edges can be smoothed c<strong>on</strong>siderably,<br />

especially if you catch the fillet at just the right stage<br />

in the cure cycle. This saves a lot of sanding later <strong>on</strong>.<br />

When the fillet has achieved a full cure, you can, of<br />

course, sand it as smooth as desired, but this is hard<br />

work, especially with a high-density fillet. Fortunately, a<br />

properly installed fillet should need very little sanding<br />

to achieve adequate smoothness. Usually we use handheld<br />

80-grit sandpaper for smoothing fillets, being<br />

careful not to damage any wood grain <strong>on</strong> either side of<br />

the fillet. When the fillet is completed, we always apply<br />

<strong>on</strong>e coat of unthickened epoxy over the entire fillet<br />

surface. You can do this when you apply a coat of<br />

epoxy to the general area.<br />

Figure 11-22 An alternative filleting tool can be made by<br />

cutting an 808 Plastic Spreader with the desired fillet radius<br />

and the adjoining sides at 75° angle. With an adequate amount<br />

of thickened epoxy in the joint and by holding the tool at the<br />

proper angle you can make a smooth fillet in <strong>on</strong>e pass. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

sides of the tool will force all of the excess epoxy toward the<br />

fillet and leave a clean margin <strong>on</strong> either side.