The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 22 – Stringer-Frame C<strong>on</strong>structi<strong>on</strong> 255<br />

a little easier to sight al<strong>on</strong>g the hull because you are<br />

dealing with a solid surface that offers more telltale signs<br />

of humps and hollows that might be present. With the<br />

stringer-frame method, the planing that you do <strong>on</strong> <strong>on</strong>e<br />

stringer or <strong>on</strong>e frame affects a large surface area in<br />

determining hull fairness. A good fairing batten and<br />

careful eyeballing will help you to achieve good overall<br />

fairness. Develop athwartship fairness by running the<br />

fairing battens at diag<strong>on</strong>al angles, as well as right angles,<br />

to the stringers. Check l<strong>on</strong>gitudinal fairness by sighting<br />

al<strong>on</strong>g your permanent stringers. In any areas of possible<br />

irregularity, clamp a large batten <strong>on</strong>to the offending<br />

stringer to see if it is, in fact, bending fair according to<br />

the batten. <str<strong>on</strong>g>The</str<strong>on</strong>g> favored tools for final fairing operati<strong>on</strong>s<br />

are a small hand-held block plane, a smoothing plane<br />

(keep both fine set and very sharp), and an 11" (280mm),<br />

flat wood sanding block with 50-grit sandpaper.<br />

I-Beam Frames<br />

With the stringer-frame system, it’s possible to build a<br />

permanent, I-beam-type frame. <str<strong>on</strong>g>The</str<strong>on</strong>g> benefit of doing<br />

this is that it can greatly stiffen the hull locally while<br />

taking up little interior space. This type of framing is<br />

not usually required throughout a hull, but it can be<br />

very useful in an area of hard curves. We sometimes use<br />

it, too, for deck c<strong>on</strong>structi<strong>on</strong>.<br />

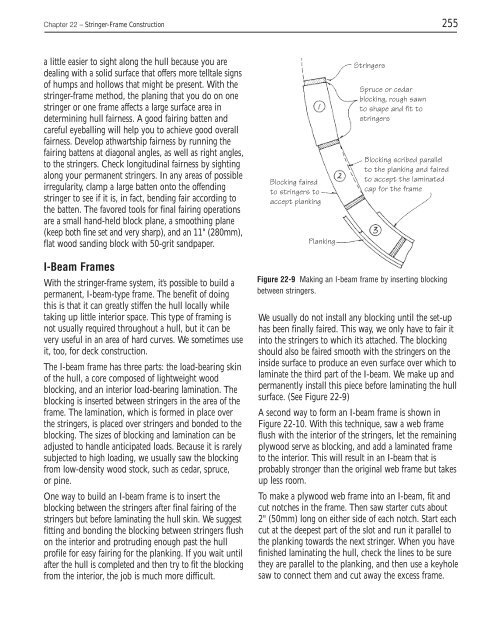

<str<strong>on</strong>g>The</str<strong>on</strong>g> I-beam frame has three parts: the load-bearing skin<br />

of the hull, a core composed of lightweight wood<br />

blocking, and an interior load-bearing laminati<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

blocking is inserted between stringers in the area of the<br />

frame. <str<strong>on</strong>g>The</str<strong>on</strong>g> laminati<strong>on</strong>, which is formed in place over<br />

the stringers, is placed over stringers and b<strong>on</strong>ded to the<br />

blocking. <str<strong>on</strong>g>The</str<strong>on</strong>g> sizes of blocking and laminati<strong>on</strong> can be<br />

adjusted to handle anticipated loads. Because it is rarely<br />

subjected to high loading, we usually saw the blocking<br />

from low-density wood stock, such as cedar, spruce,<br />

or pine.<br />

One way to build an I-beam frame is to insert the<br />

blocking between the stringers after final fairing of the<br />

stringers but before laminating the hull skin. We suggest<br />

fitting and b<strong>on</strong>ding the blocking between stringers flush<br />

<strong>on</strong> the interior and protruding enough past the hull<br />

profile for easy fairing for the planking. If you wait until<br />

after the hull is completed and then try to fit the blocking<br />

from the interior, the job is much more difficult.<br />

Blocking faired<br />

to stringers to<br />

accept planking<br />

Planking<br />

Stringers<br />

Spruce or cedar<br />

blocking, rough sawn<br />

to shape and fit to<br />

stringers<br />

Blocking scribed parallel<br />

to the planking and faired<br />

to accept the laminated<br />

cap for the frame<br />

Figure 22-9 Making an I-beam frame by inserting blocking<br />

between stringers.<br />

We usually do not install any blocking until the set-up<br />

has been finally faired. This way, we <strong>on</strong>ly have to fair it<br />

into the stringers to which it’s attached. <str<strong>on</strong>g>The</str<strong>on</strong>g> blocking<br />

should also be faired smooth with the stringers <strong>on</strong> the<br />

inside surface to produce an even surface over which to<br />

laminate the third part of the I-beam. We make up and<br />

permanently install this piece before laminating the hull<br />

surface. (See Figure 22-9)<br />

A sec<strong>on</strong>d way to form an I-beam frame is shown in<br />

Figure 22-10. With this technique, saw a web frame<br />

flush with the interior of the stringers, let the remaining<br />

plywood serve as blocking, and add a laminated frame<br />

to the interior. This will result in an I-beam that is<br />

probably str<strong>on</strong>ger than the original web frame but takes<br />

up less room.<br />

To make a plywood web frame into an I-beam, fit and<br />

cut notches in the frame. <str<strong>on</strong>g>The</str<strong>on</strong>g>n saw starter cuts about<br />

2" (50mm) l<strong>on</strong>g <strong>on</strong> either side of each notch. Start each<br />

cut at the deepest part of the slot and run it parallel to<br />

the planking towards the next stringer. When you have<br />

finished laminating the hull, check the lines to be sure<br />

they are parallel to the planking, and then use a keyhole<br />

saw to c<strong>on</strong>nect them and cut away the excess frame.