The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

390 Appendices<br />

Maximum Stress (x 1000 psi)<br />

Cycles<br />

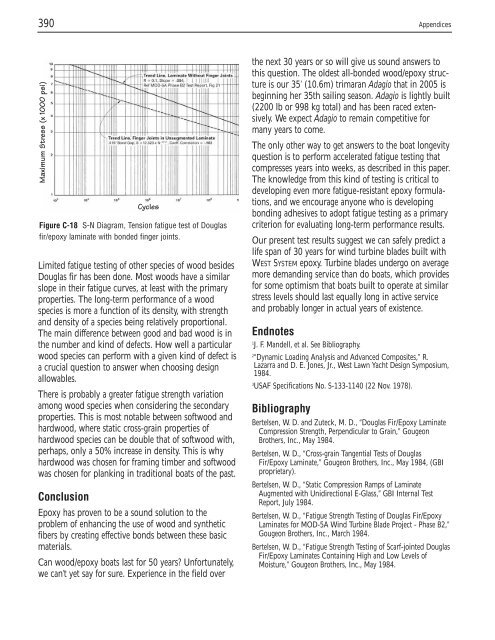

Figure C-18 S-N Diagram, Tensi<strong>on</strong> fatigue test of Douglas<br />

fir/epoxy laminate with b<strong>on</strong>ded finger joints.<br />

Limited fatigue testing of other species of wood besides<br />

Douglas fir has been d<strong>on</strong>e. Most woods have a similar<br />

slope in their fatigue curves, at least with the primary<br />

properties. <str<strong>on</strong>g>The</str<strong>on</strong>g> l<strong>on</strong>g-term performance of a wood<br />

species is more a functi<strong>on</strong> of its density, with strength<br />

and density of a species being relatively proporti<strong>on</strong>al.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> main difference between good and bad wood is in<br />

the number and kind of defects. How well a particular<br />

wood species can perform with a given kind of defect is<br />

a crucial questi<strong>on</strong> to answer when choosing design<br />

allowables.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re is probably a greater fatigue strength variati<strong>on</strong><br />

am<strong>on</strong>g wood species when c<strong>on</strong>sidering the sec<strong>on</strong>dary<br />

properties. This is most notable between softwood and<br />

hardwood, where static cross-grain properties of<br />

hardwood species can be double that of softwood with,<br />

perhaps, <strong>on</strong>ly a 50% increase in density. This is why<br />

hardwood was chosen for framing timber and softwood<br />

was chosen for planking in traditi<strong>on</strong>al boats of the past.<br />

C<strong>on</strong>clusi<strong>on</strong><br />

<strong>Epoxy</strong> has proven to be a sound soluti<strong>on</strong> to the<br />

problem of enhancing the use of wood and synthetic<br />

fibers by creating effective b<strong>on</strong>ds between these basic<br />

materials.<br />

Can wood/epoxy boats last for 50 years? Unfortunately,<br />

we can’t yet say for sure. Experience in the field over<br />

the next 30 years or so will give us sound answers to<br />

this questi<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g> oldest all-b<strong>on</strong>ded wood/epoxy structure<br />

is our 35’ (10.6m) trimaran Adagio that in 2005 is<br />

beginning her 35th sailing seas<strong>on</strong>. Adagio is lightly built<br />

(2200 lb or 998 kg total) and has been raced extensively.<br />

We expect Adagio to remain competitive for<br />

many years to come.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> <strong>on</strong>ly other way to get answers to the boat l<strong>on</strong>gevity<br />

questi<strong>on</strong> is to perform accelerated fatigue testing that<br />

compresses years into weeks, as described in this paper.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> knowledge from this kind of testing is critical to<br />

developing even more fatigue-resistant epoxy formulati<strong>on</strong>s,<br />

and we encourage any<strong>on</strong>e who is developing<br />

b<strong>on</strong>ding adhesives to adopt fatigue testing as a primary<br />

criteri<strong>on</strong> for evaluating l<strong>on</strong>g-term performance results.<br />

Our present test results suggest we can safely predict a<br />

life span of 30 years for wind turbine blades built with<br />

<strong>WEST</strong> <strong>SYSTEM</strong> epoxy. Turbine blades undergo <strong>on</strong> average<br />

more demanding service than do boats, which provides<br />

for some optimism that boats built to operate at similar<br />

stress levels should last equally l<strong>on</strong>g in active service<br />

and probably l<strong>on</strong>ger in actual years of existence.<br />

Endnotes<br />

1J. F. Mandell, et al. See Bibliography.<br />

2 “Dynamic Loading Analysis and Advanced Composites,” R.<br />

Lazarra and D. E. J<strong>on</strong>es, Jr., West Lawn Yacht Design Symposium,<br />

1984.<br />

3USAF Specificati<strong>on</strong>s No. S-133-1140 (22 Nov. 1978).<br />

Bibliography<br />

Bertelsen, W. D. and Zuteck, M. D., “Douglas Fir/<strong>Epoxy</strong> Laminate<br />

Compressi<strong>on</strong> Strength, Perpendicular to Grain,” <str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g><br />

<str<strong>on</strong>g>Brothers</str<strong>on</strong>g>, Inc., May 1984.<br />

Bertelsen, W. D., “Cross-grain Tangential Tests of Douglas<br />

Fir/<strong>Epoxy</strong> Laminate,” <str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Brothers</str<strong>on</strong>g>, Inc., May 1984, (GBI<br />

proprietary).<br />

Bertelsen, W. D., “Static Compressi<strong>on</strong> Ramps of Laminate<br />

Augmented with Unidirecti<strong>on</strong>al E-Glass,” GBI Internal Test<br />

Report, July 1984.<br />

Bertelsen, W. D., “Fatigue Strength Testing of Douglas Fir/<strong>Epoxy</strong><br />

Laminates for MOD-5A Wind Turbine Blade Project - Phase B2,”<br />

<str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Brothers</str<strong>on</strong>g>, Inc., March 1984.<br />

Bertelsen, W. D., “Fatigue Strength Testing of Scarf-jointed Douglas<br />

Fir/<strong>Epoxy</strong> Laminates C<strong>on</strong>taining High and Low Levels of<br />

Moisture,” <str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Brothers</str<strong>on</strong>g>, Inc., May 1984.