The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

298 Hull C<strong>on</strong>structi<strong>on</strong> Methods<br />

snugly. In some cases you can force wires to the left or<br />

right as you twist them to assist in raising or lowering<br />

<strong>on</strong>e panel edge against the other. <str<strong>on</strong>g>The</str<strong>on</strong>g> goal of this final<br />

tightening is to snug the plywood panels against each<br />

other and to line them up so that there will be no<br />

humps and hollows al<strong>on</strong>g the keel line.<br />

Occasi<strong>on</strong>ally, wire ties may be mutilated to the point<br />

where you lose c<strong>on</strong>trol of the plywood edges around<br />

them. <str<strong>on</strong>g>The</str<strong>on</strong>g> best soluti<strong>on</strong> to this problem is to snip these<br />

wires, remove them, start over with fresh ties, and hope<br />

for better luck. Drill more holes and insert extra wires<br />

in areas that are particularly difficult. If you have further<br />

trouble, it’s more than likely that you did not put enough<br />

radius <strong>on</strong> your edges and/or that a hump or hollow <strong>on</strong><br />

a panel edge is throwing alignment out of kilter.<br />

C<strong>on</strong>structing the Keel Joint<br />

When the keel edges of the plywood panels are in<br />

positi<strong>on</strong> and any wires tightened, begin the process of<br />

building a keel joint. We recommend that you plan to<br />

manufacture the keel in a single day as this will eliminate<br />

sanding between layers.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> composite keel joint is <strong>on</strong>e of the most critical<br />

parts of a compounded plywood hull. Although the size<br />

and compositi<strong>on</strong> of keel joints vary from hull to hull,<br />

basic installati<strong>on</strong> procedure is very similar. Begin by<br />

filling the V formed by the two panels at the interior<br />

keel line with a fillet of thickened epoxy, lay in fiberglass<br />

cloth or tape, and apply more epoxy and fiberglass<br />

cloth. <str<strong>on</strong>g>The</str<strong>on</strong>g> epoxy structurally joins the panels and, at<br />

the same time, serves as a core between the inner and<br />

outer layers of fiberglass.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are no firm rules for the thickness and width of<br />

composite keels, but the fillet should at least cover<br />

protruding wires if you are using them so that you can<br />

evenly apply the glass over a smooth surface. <str<strong>on</strong>g>The</str<strong>on</strong>g> size<br />

of a keel joint, and especially its width, has a significant<br />

effect <strong>on</strong> the shape of the finished hull, and it is a<br />

rather rigid part of the structure, which for the most<br />

part will not bend. If it is irregular, larger in some areas<br />

than in others, it may cause bumps and hollows.<br />

Variati<strong>on</strong> of around 10% in the keel secti<strong>on</strong> is tolerable,<br />

but any more than this will lead to unfairness in the<br />

hull. (See Figure 25-9.)<br />

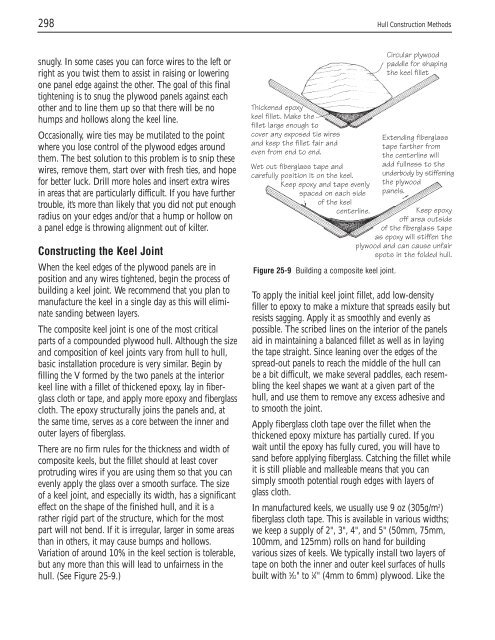

Thickened epoxy<br />

keel fillet. Make the<br />

fillet large enough to<br />

cover any exposed tie wires<br />

and keep the fillet fair and<br />

even from end to end.<br />

Wet out fiberglass tape and<br />

carefully positi<strong>on</strong> it <strong>on</strong> the keel.<br />

Keep epoxy and tape evenly<br />

spaced <strong>on</strong> each side<br />

of the keel<br />

centerline.<br />

Figure 25-9 Building a composite keel joint.<br />

Circular plywood<br />

paddle for shaping<br />

the keel fillet<br />

Extending fiberglass<br />

tape farther from<br />

the centerline will<br />

add fullness to the<br />

underbody by stiffening<br />

the plywood<br />

panels.<br />

Keep epoxy<br />

off area outside<br />

of the fiberglass tape<br />

as epoxy will stiffen the<br />

plywood and can cause unfair<br />

spots in the folded hull.<br />

To apply the initial keel joint fillet, add low-density<br />

filler to epoxy to make a mixture that spreads easily but<br />

resists sagging. Apply it as smoothly and evenly as<br />

possible. <str<strong>on</strong>g>The</str<strong>on</strong>g> scribed lines <strong>on</strong> the interior of the panels<br />

aid in maintaining a balanced fillet as well as in laying<br />

the tape straight. Since leaning over the edges of the<br />

spread-out panels to reach the middle of the hull can<br />

be a bit difficult, we make several paddles, each resembling<br />

the keel shapes we want at a given part of the<br />

hull, and use them to remove any excess adhesive and<br />

to smooth the joint.<br />

Apply fiberglass cloth tape over the fillet when the<br />

thickened epoxy mixture has partially cured. If you<br />

wait until the epoxy has fully cured, you will have to<br />

sand before applying fiberglass. Catching the fillet while<br />

it is still pliable and malleable means that you can<br />

simply smooth potential rough edges with layers of<br />

glass cloth.<br />

In manufactured keels, we usually use 9 oz (305g/m2 )<br />

fiberglass cloth tape. This is available in various widths;<br />

we keep a supply of 2", 3", 4", and 5" (50mm, 75mm,<br />

100mm, and 125mm) rolls <strong>on</strong> hand for building<br />

various sizes of keels. We typically install two layers of<br />

tape <strong>on</strong> both the inner and outer keel surfaces of hulls<br />

built with 5 ⁄32" to 1 ⁄4" (4mm to 6mm) plywood. Like the