The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 11 – Laminating and B<strong>on</strong>ding Techniques 103<br />

X<br />

Load<br />

8X<br />

A High-Density Fillet<br />

Experimentati<strong>on</strong> with the<br />

fillet can produce a joint<br />

str<strong>on</strong>g enough that failure<br />

will occur in the plywood<br />

rather than in the<br />

wood-epoxy b<strong>on</strong>d.<br />

Plywood Fillet<br />

thickness radius<br />

High-density fillets 5<br />

⁄32" (4mm) 5 ⁄8" (15mm)<br />

3<br />

⁄16" (5mm)<br />

3 ⁄4" (18mm)<br />

1 ⁄4" (6mm)<br />

7 ⁄8" (22mm)<br />

Low-density fillets 5<br />

⁄32" (4mm) 3 1 ⁄4" (44mm)<br />

3<br />

⁄16" (5mm) 3 1 ⁄4" (44mm)<br />

1 ⁄4" (6mm) 3 1 ⁄4" (44mm)<br />

Fillet fails in tensi<strong>on</strong><br />

and starts wood<br />

failure al<strong>on</strong>g<br />

grain.<br />

Low-density<br />

fillet compresses<br />

under load.<br />

A Low-Density Fillet<br />

Wood failure<br />

al<strong>on</strong>g the base<br />

of the joint.<br />

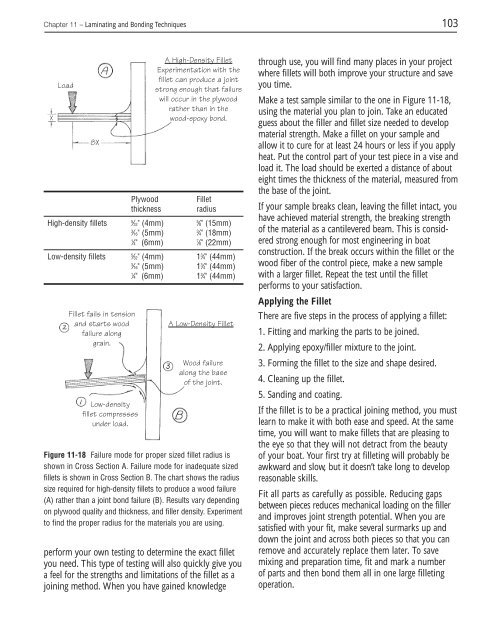

Figure 11-18 Failure mode for proper sized fillet radius is<br />

shown in Cross Secti<strong>on</strong> A. Failure mode for inadequate sized<br />

fillets is shown in Cross Secti<strong>on</strong> B. <str<strong>on</strong>g>The</str<strong>on</strong>g> chart shows the radius<br />

size required for high-density fillets to produce a wood failure<br />

(A) rather than a joint b<strong>on</strong>d failure (B). Results vary depending<br />

<strong>on</strong> plywood quality and thickness, and filler density. Experiment<br />

to find the proper radius for the materials you are using.<br />

perform your own testing to determine the exact fillet<br />

you need. This type of testing will also quickly give you<br />

a feel for the strengths and limitati<strong>on</strong>s of the fillet as a<br />

joining method. When you have gained knowledge<br />

through use, you will find many places in your project<br />

where fillets will both improve your structure and save<br />

you time.<br />

Make a test sample similar to the <strong>on</strong>e in Figure 11-18,<br />

using the material you plan to join. Take an educated<br />

guess about the filler and fillet size needed to develop<br />

material strength. Make a fillet <strong>on</strong> your sample and<br />

allow it to cure for at least 24 hours or less if you apply<br />

heat. Put the c<strong>on</strong>trol part of your test piece in a vise and<br />

load it. <str<strong>on</strong>g>The</str<strong>on</strong>g> load should be exerted a distance of about<br />

eight times the thickness of the material, measured from<br />

the base of the joint.<br />

If your sample breaks clean, leaving the fillet intact, you<br />

have achieved material strength, the breaking strength<br />

of the material as a cantilevered beam. This is c<strong>on</strong>sidered<br />

str<strong>on</strong>g enough for most engineering in boat<br />

c<strong>on</strong>structi<strong>on</strong>. If the break occurs within the fillet or the<br />

wood fiber of the c<strong>on</strong>trol piece, make a new sample<br />

with a larger fillet. Repeat the test until the fillet<br />

performs to your satisfacti<strong>on</strong>.<br />

Applying the Fillet<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are five steps in the process of applying a fillet:<br />

1. Fitting and marking the parts to be joined.<br />

2. Applying epoxy/filler mixture to the joint.<br />

3. Forming the fillet to the size and shape desired.<br />

4. Cleaning up the fillet.<br />

5. Sanding and coating.<br />

If the fillet is to be a practical joining method, you must<br />

learn to make it with both ease and speed. At the same<br />

time, you will want to make fillets that are pleasing to<br />

the eye so that they will not detract from the beauty<br />

of your boat. Your first try at filleting will probably be<br />

awkward and slow, but it doesn’t take l<strong>on</strong>g to develop<br />

reas<strong>on</strong>able skills.<br />

Fit all parts as carefully as possible. Reducing gaps<br />

between pieces reduces mechanical loading <strong>on</strong> the filler<br />

and improves joint strength potential. When you are<br />

satisfied with your fit, make several surmarks up and<br />

down the joint and across both pieces so that you can<br />

remove and accurately replace them later. To save<br />

mixing and preparati<strong>on</strong> time, fit and mark a number<br />

of parts and then b<strong>on</strong>d them all in <strong>on</strong>e large filleting<br />

operati<strong>on</strong>.