The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 23 – Strip Plank Laminated Veneer and Strip Composite C<strong>on</strong>structi<strong>on</strong> 269<br />

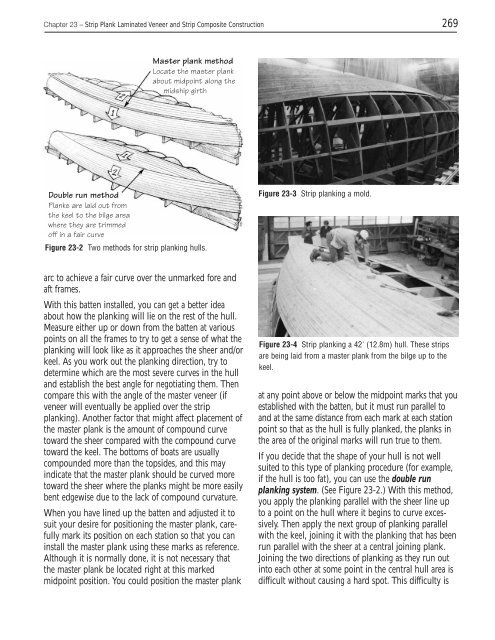

Double run method<br />

Planks are laid out from<br />

the keel to the bilge area<br />

where they are trimmed<br />

off in a fair curve<br />

Master plank method<br />

Locate the master plank<br />

about midpoint al<strong>on</strong>g the<br />

midship girth<br />

Figure 23-2 Two methods for strip planking hulls.<br />

arc to achieve a fair curve over the unmarked fore and<br />

aft frames.<br />

With this batten installed, you can get a better idea<br />

about how the planking will lie <strong>on</strong> the rest of the hull.<br />

Measure either up or down from the batten at various<br />

points <strong>on</strong> all the frames to try to get a sense of what the<br />

planking will look like as it approaches the sheer and/or<br />

keel. As you work out the planking directi<strong>on</strong>, try to<br />

determine which are the most severe curves in the hull<br />

and establish the best angle for negotiating them. <str<strong>on</strong>g>The</str<strong>on</strong>g>n<br />

compare this with the angle of the master veneer (if<br />

veneer will eventually be applied over the strip<br />

planking). Another factor that might affect placement of<br />

the master plank is the amount of compound curve<br />

toward the sheer compared with the compound curve<br />

toward the keel. <str<strong>on</strong>g>The</str<strong>on</strong>g> bottoms of boats are usually<br />

compounded more than the topsides, and this may<br />

indicate that the master plank should be curved more<br />

toward the sheer where the planks might be more easily<br />

bent edgewise due to the lack of compound curvature.<br />

When you have lined up the batten and adjusted it to<br />

suit your desire for positi<strong>on</strong>ing the master plank, carefully<br />

mark its positi<strong>on</strong> <strong>on</strong> each stati<strong>on</strong> so that you can<br />

install the master plank using these marks as reference.<br />

Although it is normally d<strong>on</strong>e, it is not necessary that<br />

the master plank be located right at this marked<br />

midpoint positi<strong>on</strong>. You could positi<strong>on</strong> the master plank<br />

Figure 23-3 Strip planking a mold.<br />

Figure 23-4 Strip planking a 42' (12.8m) hull. <str<strong>on</strong>g>The</str<strong>on</strong>g>se strips<br />

are being laid from a master plank from the bilge up to the<br />

keel.<br />

at any point above or below the midpoint marks that you<br />

established with the batten, but it must run parallel to<br />

and at the same distance from each mark at each stati<strong>on</strong><br />

point so that as the hull is fully planked, the planks in<br />

the area of the original marks will run true to them.<br />

If you decide that the shape of your hull is not well<br />

suited to this type of planking procedure (for example,<br />

if the hull is too fat), you can use the double run<br />

planking system. (See Figure 23-2.) With this method,<br />

you apply the planking parallel with the sheer line up<br />

to a point <strong>on</strong> the hull where it begins to curve excessively.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>n apply the next group of planking parallel<br />

with the keel, joining it with the planking that has been<br />

run parallel with the sheer at a central joining plank.<br />

Joining the two directi<strong>on</strong>s of planking as they run out<br />

into each other at some point in the central hull area is<br />

difficult without causing a hard spot. This difficulty is