The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

250 Hull C<strong>on</strong>structi<strong>on</strong> Methods<br />

plank methods, you notch them into all of the frames<br />

and bulkheads so that they are flush with the outer<br />

edges of these parts. Stringers are also let into the back<br />

of the stem, with their outer edges flush with the faired<br />

stem surface. Layers of hull skin are b<strong>on</strong>ded to all of<br />

these parts and help to join them.<br />

Stringers for Stringer-Frame C<strong>on</strong>structi<strong>on</strong><br />

Stringers, like frames, serve two functi<strong>on</strong>s. <str<strong>on</strong>g>The</str<strong>on</strong>g>y, too,<br />

form a reas<strong>on</strong>ably substantial mold shape as the hull is<br />

built and support it when it is finished. It’s difficult to<br />

temporarily reinforce stringers for laminating, so mold<br />

requirements supersede the requirements of the<br />

completed hull. Chances are that you will end up using<br />

more stringers than the structure actually needs in order<br />

to have a decent mold. Stringers may, however, be<br />

planed to smaller size after the hull skin has been<br />

laminated.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> main requirement of a stringer is that it not bend<br />

or deflect as veneer or plywood is bent around it during<br />

laminating. To minimize distorti<strong>on</strong>, we always set<br />

stringers <strong>on</strong> edge, with the smaller dimensi<strong>on</strong>, or thickness,<br />

touching the skin, while the larger dimensi<strong>on</strong>, or<br />

depth, extends inward. A typical stringer for a 40'<br />

(12.2m) boat is 11 ⁄2" (38mm) deep and 3 ⁄4" (18mm)<br />

thick. We attach the 3 ⁄4" side to the skin and run the 11 ⁄2"<br />

side towards the interior. This makes a T-secti<strong>on</strong>, which<br />

gives the completed hull great stiffness and strength. If<br />

the stringer was attached to the skin by its 11 ⁄2" side, it<br />

would provide <strong>on</strong>ly about <strong>on</strong>e third of the stiffness it<br />

offers in the 3 ⁄4" dimensi<strong>on</strong>, and it would probably deform<br />

during laminating. This might lead to an unfair hull.<br />

Since you will be stapling veneer and plywood to the<br />

edge of the stringer, it must be thick enough to permit<br />

stapling without a lot of misses. Although it’s easy for a<br />

staple to miss even a thick stringer and missed staples<br />

can be removed before the next layer is applied, 3 ⁄4"<br />

(18mm) is a practical stringer thickness for stapling. We<br />

regularly, however, go down to 5 ⁄8" (15mm) with little<br />

difficulty. Thinner stringers can be used, but may<br />

require very time-c<strong>on</strong>suming and exact measuring to<br />

avoid misses.<br />

Another c<strong>on</strong>siderati<strong>on</strong> determining stringer size is the<br />

ability of the stringer to bend around the most severe<br />

curves in the hull shape. In certain situati<strong>on</strong>s, it may be<br />

necessary to laminate stringers out of two or three pieces<br />

to negotiate a curve. If so, use the set-up as a temporary<br />

form <strong>on</strong> which to clamp and form the laminate until<br />

the adhesive cures. <str<strong>on</strong>g>The</str<strong>on</strong>g>n remove the laminated stringer<br />

from the set-up and prefinish it prior to reinstalling it<br />

into the set-up. <str<strong>on</strong>g>The</str<strong>on</strong>g> laminated stringer has the big<br />

advantage in that it is sure to be very stiff and will resist<br />

deflecti<strong>on</strong> during the veneer laminating process.<br />

Because of the variables involved, it is difficult to give<br />

advice as to stringer size adequate to resist deflecti<strong>on</strong><br />

during laminating. Usually you can determine this for<br />

yourself by creating a mock-up situati<strong>on</strong> where you set<br />

a given size stringer between two points that would<br />

approximate the frame spacing. By bending some of<br />

your laminate stock over this stringer, you can get a<br />

general idea as to whether or not it will be adequate. As<br />

a general guideline, a 11 ⁄2" � 3 ⁄4" (38mm � 18mm)<br />

stringer is adequate for most laminating situati<strong>on</strong>s<br />

when used <strong>on</strong> frame spacings up to 24" (600mm).<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> next decisi<strong>on</strong> is the spacing of the stringer al<strong>on</strong>g<br />

the frames. Initially it isn’t a questi<strong>on</strong> of how many<br />

stringers are needed in the completed hull, but of the<br />

minimum number of stringers necessary for proper<br />

laminating to take place. Once again, the needs of the<br />

hull structure and those of the mold are different.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> main factor that determines stringer spacing is the<br />

shape of the hull itself. In areas with more curve, tighter<br />

spacing of stringers may be needed to define the hull<br />

shape properly, while flatter areas can rely <strong>on</strong> fewer<br />

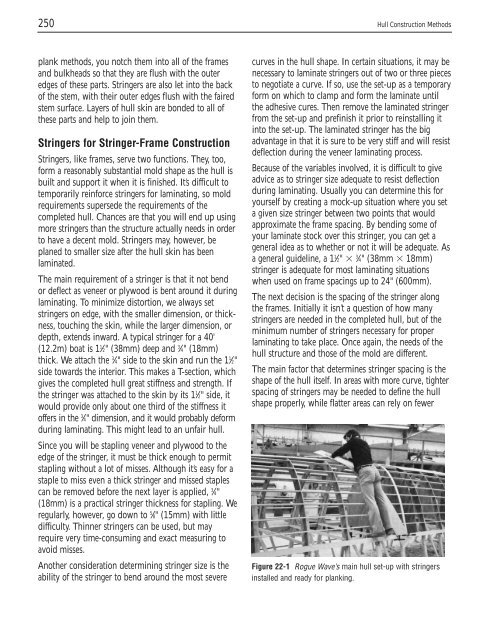

Figure 22-1 Rogue Wave’s main hull set-up with stringers<br />

installed and ready for planking.