The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 24 – Hard Chine Plywood C<strong>on</strong>structi<strong>on</strong> 289<br />

Figure 24-8 Applying adhesive mixture before b<strong>on</strong>ding a<br />

panel to the framework. <str<strong>on</strong>g>The</str<strong>on</strong>g> panel lying against the framework<br />

in the foreground will be scarfed in place.<br />

If you are using 3 ⁄8" (9mm) or thicker plywood, you can<br />

scarf in place <strong>on</strong> the hull without worrying about<br />

locating the joint over a solid member. In situati<strong>on</strong>s<br />

where you find that your sheet is <strong>on</strong>ly a few inches<br />

short of a frame and that you will have to cut off a<br />

substantial amount of material to retreat to the previous<br />

frame, the ability to scarf anywhere saves a great deal of<br />

plywood. Marking is simplified because the scarf<br />

doesn’t have to be centered <strong>on</strong> a fixed point. Make sure,<br />

however, that there is enough l<strong>on</strong>gitudinal support<br />

between the two panels to keep them reas<strong>on</strong>ably<br />

aligned as you scarf.<br />

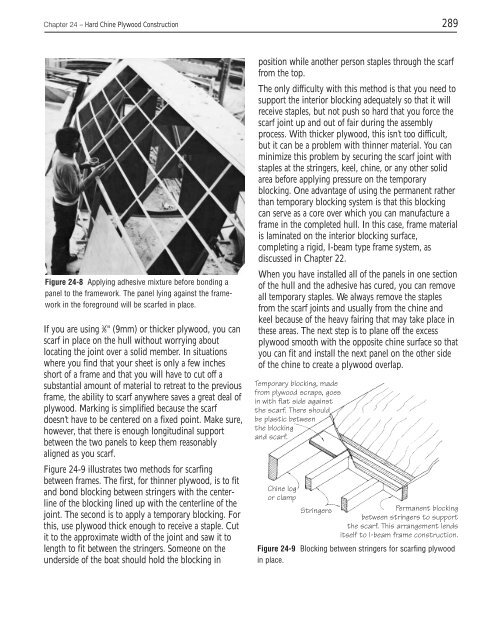

Figure 24-9 illustrates two methods for scarfing<br />

between frames. <str<strong>on</strong>g>The</str<strong>on</strong>g> first, for thinner plywood, is to fit<br />

and b<strong>on</strong>d blocking between stringers with the centerline<br />

of the blocking lined up with the centerline of the<br />

joint. <str<strong>on</strong>g>The</str<strong>on</strong>g> sec<strong>on</strong>d is to apply a temporary blocking. For<br />

this, use plywood thick enough to receive a staple. Cut<br />

it to the approximate width of the joint and saw it to<br />

length to fit between the stringers. Some<strong>on</strong>e <strong>on</strong> the<br />

underside of the boat should hold the blocking in<br />

positi<strong>on</strong> while another pers<strong>on</strong> staples through the scarf<br />

from the top.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> <strong>on</strong>ly difficulty with this method is that you need to<br />

support the interior blocking adequately so that it will<br />

receive staples, but not push so hard that you force the<br />

scarf joint up and out of fair during the assembly<br />

process. With thicker plywood, this isn’t too difficult,<br />

but it can be a problem with thinner material. You can<br />

minimize this problem by securing the scarf joint with<br />

staples at the stringers, keel, chine, or any other solid<br />

area before applying pressure <strong>on</strong> the temporary<br />

blocking. One advantage of using the permanent rather<br />

than temporary blocking system is that this blocking<br />

can serve as a core over which you can manufacture a<br />

frame in the completed hull. In this case, frame material<br />

is laminated <strong>on</strong> the interior blocking surface,<br />

completing a rigid, I-beam type frame system, as<br />

discussed in Chapter 22.<br />

When you have installed all of the panels in <strong>on</strong>e secti<strong>on</strong><br />

of the hull and the adhesive has cured, you can remove<br />

all temporary staples. We always remove the staples<br />

from the scarf joints and usually from the chine and<br />

keel because of the heavy fairing that may take place in<br />

these areas. <str<strong>on</strong>g>The</str<strong>on</strong>g> next step is to plane off the excess<br />

plywood smooth with the opposite chine surface so that<br />

you can fit and install the next panel <strong>on</strong> the other side<br />

of the chine to create a plywood overlap.<br />

Temporary blocking, made<br />

from plywood scraps, goes<br />

in with flat side against<br />

the scarf. <str<strong>on</strong>g>The</str<strong>on</strong>g>re should<br />

be plastic between<br />

the blocking<br />

and scarf.<br />

Chine log<br />

or clamp<br />

Stringers<br />

Permanent blocking<br />

between stringers to support<br />

the scarf. This arrangement lends<br />

itself to I-beam frame c<strong>on</strong>structi<strong>on</strong>.<br />

Figure 24-9 Blocking between stringers for scarfing plywood<br />

in place.