The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

274 Hull C<strong>on</strong>structi<strong>on</strong> Methods<br />

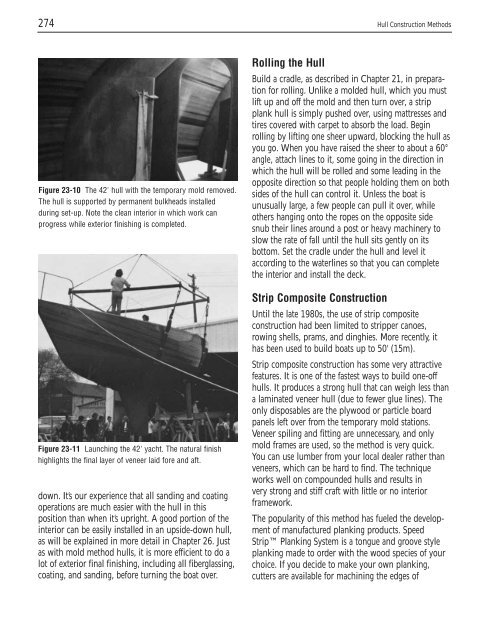

Figure 23-10 <str<strong>on</strong>g>The</str<strong>on</strong>g> 42' hull with the temporary mold removed.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> hull is supported by permanent bulkheads installed<br />

during set-up. Note the clean interior in which work can<br />

progress while exterior finishing is completed.<br />

Figure 23-11 Launching the 42' yacht. <str<strong>on</strong>g>The</str<strong>on</strong>g> natural finish<br />

highlights the final layer of veneer laid fore and aft.<br />

down. It’s our experience that all sanding and coating<br />

operati<strong>on</strong>s are much easier with the hull in this<br />

positi<strong>on</strong> than when it’s upright. A good porti<strong>on</strong> of the<br />

interior can be easily installed in an upside-down hull,<br />

as will be explained in more detail in Chapter 26. Just<br />

as with mold method hulls, it is more efficient to do a<br />

lot of exterior final finishing, including all fiberglassing,<br />

coating, and sanding, before turning the boat over.<br />

Rolling the Hull<br />

Build a cradle, as described in Chapter 21, in preparati<strong>on</strong><br />

for rolling. Unlike a molded hull, which you must<br />

lift up and off the mold and then turn over, a strip<br />

plank hull is simply pushed over, using mattresses and<br />

tires covered with carpet to absorb the load. Begin<br />

rolling by lifting <strong>on</strong>e sheer upward, blocking the hull as<br />

you go. When you have raised the sheer to about a 60°<br />

angle, attach lines to it, some going in the directi<strong>on</strong> in<br />

which the hull will be rolled and some leading in the<br />

opposite directi<strong>on</strong> so that people holding them <strong>on</strong> both<br />

sides of the hull can c<strong>on</strong>trol it. Unless the boat is<br />

unusually large, a few people can pull it over, while<br />

others hanging <strong>on</strong>to the ropes <strong>on</strong> the opposite side<br />

snub their lines around a post or heavy machinery to<br />

slow the rate of fall until the hull sits gently <strong>on</strong> its<br />

bottom. Set the cradle under the hull and level it<br />

according to the waterlines so that you can complete<br />

the interior and install the deck.<br />

Strip Composite C<strong>on</strong>structi<strong>on</strong><br />

Until the late 1980s, the use of strip composite<br />

c<strong>on</strong>structi<strong>on</strong> had been limited to stripper canoes,<br />

rowing shells, prams, and dinghies. More recently, it<br />

has been used to build boats up to 50' (15m).<br />

Strip composite c<strong>on</strong>structi<strong>on</strong> has some very attractive<br />

features. It is <strong>on</strong>e of the fastest ways to build <strong>on</strong>e-off<br />

hulls. It produces a str<strong>on</strong>g hull that can weigh less than<br />

a laminated veneer hull (due to fewer glue lines). <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

<strong>on</strong>ly disposables are the plywood or particle board<br />

panels left over from the temporary mold stati<strong>on</strong>s.<br />

Veneer spiling and fitting are unnecessary, and <strong>on</strong>ly<br />

mold frames are used, so the method is very quick.<br />

You can use lumber from your local dealer rather than<br />

veneers, which can be hard to find. <str<strong>on</strong>g>The</str<strong>on</strong>g> technique<br />

works well <strong>on</strong> compounded hulls and results in<br />

very str<strong>on</strong>g and stiff craft with little or no interior<br />

framework.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> popularity of this method has fueled the development<br />

of manufactured planking products. Speed<br />

Strip Planking System is a t<strong>on</strong>gue and groove style<br />

planking made to order with the wood species of your<br />

choice. If you decide to make your own planking,<br />

cutters are available for machining the edges of