The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 21 – Laminating Veneer Over a Mold or Plug 235<br />

<strong>on</strong> them are potentially endless, we have been able to<br />

find <strong>on</strong>ly <strong>on</strong>e effective staple removing tool, a model<br />

designed for upholsterers manufactured by the Stanley<br />

Tool Company. A good tool should have a very sharp,<br />

hardened steel point which inserts easily under the<br />

crown of a staple, and it should have a fulcrum<br />

immediately aft of this point which is wide enough<br />

to prevent damage to the wood. You should be able<br />

to rock the handle to extract the staple with minimal<br />

effort. Figure 21-8 shows some of the tools we have<br />

built in the shop with these design criteria in mind.<br />

You can modify a large screwdriver by grinding its end<br />

to a sharp wide edge and by grinding a curve <strong>on</strong> <strong>on</strong>e<br />

side so that there is some rocker <strong>on</strong> the side opposite<br />

the edge. If, after grinding, you find that your fulcrum<br />

is too small, try bending the screwdriver slightly. A<br />

well-hardened screwdriver may not permit this, in<br />

which case you can b<strong>on</strong>d a piece of wood or add<br />

thickened epoxy to build up the fulcrum. Your staple<br />

remover will receive a lot of use, so it’s worth the time<br />

it takes to make a good tool that works easily and well.<br />

Applying the First Layer of Veneer<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> first layer will become the interior of your boat, so<br />

select its veneers with great care and present the finest<br />

grain and color you have. We almost always naturally<br />

finish interiors because they are beautiful and practical<br />

when d<strong>on</strong>e this way.<br />

Begin by placing a master veneer in the middle of the<br />

mold. If you start here, you can plank toward the stem<br />

and toward the transom simultaneously. If two people<br />

or teams are available, they can work in opposite directi<strong>on</strong>s.<br />

Because your angle is in the middle of the hull,<br />

it’s easier to maintain as you apply veneers. <str<strong>on</strong>g>The</str<strong>on</strong>g>re is no<br />

set rule for the angle of the first layer, but 45° is good<br />

for starters.<br />

Mark the angle of the first veneer <strong>on</strong> the polyethylene<br />

mold cover. Set your sliding bevel at the desired angle,<br />

place it <strong>on</strong> top of a level, and positi<strong>on</strong> both tools next<br />

to the hull. Move the level until its bubble is centered<br />

in its markings and transfer the angle from the bevel<br />

square to the mold. Make a mark just l<strong>on</strong>g enough to<br />

indicate the placement of the first veneer. <str<strong>on</strong>g>The</str<strong>on</strong>g>n hold<br />

the veneer <strong>on</strong> the mold and draw a line all the way<br />

across the mold surface to show its exact positi<strong>on</strong>.<br />

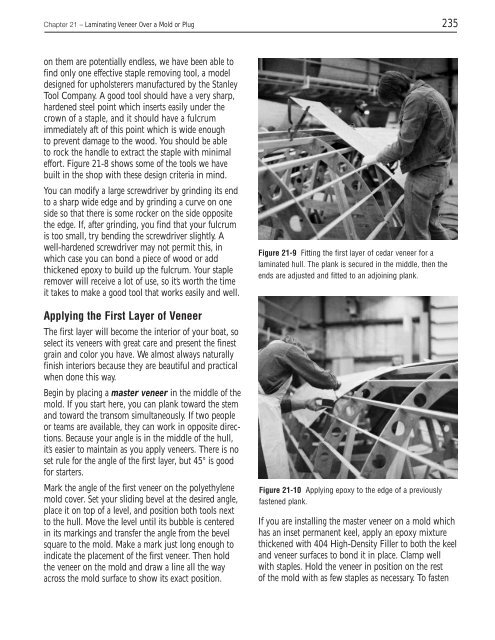

Figure 21-9 Fitting the first layer of cedar veneer for a<br />

laminated hull. <str<strong>on</strong>g>The</str<strong>on</strong>g> plank is secured in the middle, then the<br />

ends are adjusted and fitted to an adjoining plank.<br />

Figure 21-10 Applying epoxy to the edge of a previously<br />

fastened plank.<br />

If you are installing the master veneer <strong>on</strong> a mold which<br />

has an inset permanent keel, apply an epoxy mixture<br />

thickened with 404 High-Density Filler to both the keel<br />

and veneer surfaces to b<strong>on</strong>d it in place. Clamp well<br />

with staples. Hold the veneer in positi<strong>on</strong> <strong>on</strong> the rest<br />

of the mold with as few staples as necessary. To fasten