The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 9 – Buying Wood 75<br />

to slice wood thicker than 1 ⁄8" without checking and<br />

shattering, but an 1 ⁄8" veneer limit doesn’t seem to be a<br />

real disadvantage with smaller boats. L<strong>on</strong>ger hulls of<br />

50' or more can use thicker stock if it is available. In<br />

these cases, the use of thin veneer involves increased<br />

labor for extra laminati<strong>on</strong>s, and this may be a major<br />

c<strong>on</strong>cern.<br />

Commercial plywood is often used in laminating. <str<strong>on</strong>g>The</str<strong>on</strong>g>re<br />

are many areas, as will be described in later chapters,<br />

where it is a good, practical choice. Plywood has already<br />

been laminated, so its dimensi<strong>on</strong>s are stable. It is readily<br />

available. Thin plywood will not split as readily as<br />

veneer when it is bent over tight curves, and it is easy<br />

to prefinish, especially for interiors <strong>on</strong> stringer-frame<br />

hulls. Plywood does, however, have some disadvantages.<br />

It is expensive and does not have the potential<br />

strength of veneer. At least <strong>on</strong>e third of its grain runs at<br />

right angles to the remainder of it, so some compromises<br />

may be necessary when you arrange it <strong>on</strong> a hull.<br />

Veneer and Plywood<br />

Sophisticated manufacturing techniques are used to<br />

make both veneer and plywood. It’s helpful to know<br />

a little about these processes before buying either<br />

material.<br />

Veneers are thin sheets of wood, which can be of<br />

various species and in a range of thicknesses. <str<strong>on</strong>g>The</str<strong>on</strong>g>y<br />

are cut from logs in two different ways: by slicing<br />

and, more frequently, by rotary cutting or peeling.<br />

With the latter technique, the log is held <strong>on</strong> lathe-like<br />

spindles and rotated while a knife peels off a c<strong>on</strong>tinuous<br />

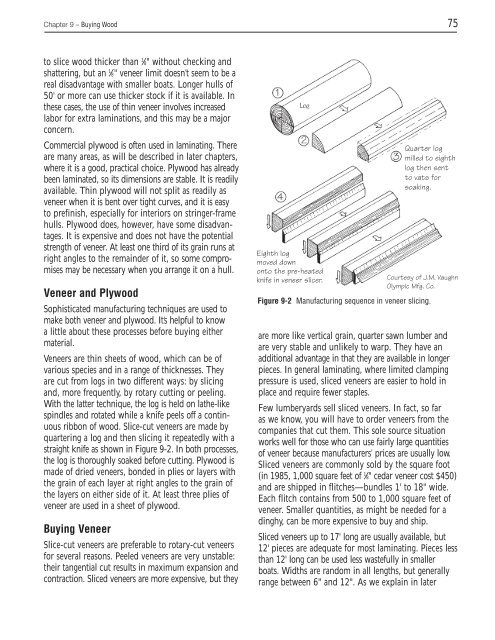

ribb<strong>on</strong> of wood. Slice-cut veneers are made by<br />

quartering a log and then slicing it repeatedly with a<br />

straight knife as shown in Figure 9-2. In both processes,<br />

the log is thoroughly soaked before cutting. Plywood is<br />

made of dried veneers, b<strong>on</strong>ded in plies or layers with<br />

the grain of each layer at right angles to the grain of<br />

the layers <strong>on</strong> either side of it. At least three plies of<br />

veneer are used in a sheet of plywood.<br />

Buying Veneer<br />

Slice-cut veneers are preferable to rotary-cut veneers<br />

for several reas<strong>on</strong>s. Peeled veneers are very unstable:<br />

their tangential cut results in maximum expansi<strong>on</strong> and<br />

c<strong>on</strong>tracti<strong>on</strong>. Sliced veneers are more expensive, but they<br />

Eighth log<br />

moved down<br />

<strong>on</strong>to the pre-heated<br />

knife in veneer slicer.<br />

Quarter log<br />

milled to eighth<br />

log then sent<br />

to vats for<br />

soaking.<br />

Courtesy of J.M. Vaughn<br />

Olympic Mfg. Co.<br />

Figure 9-2 Manufacturing sequence in veneer slicing.<br />

are more like vertical grain, quarter sawn lumber and<br />

are very stable and unlikely to warp. <str<strong>on</strong>g>The</str<strong>on</strong>g>y have an<br />

additi<strong>on</strong>al advantage in that they are available in l<strong>on</strong>ger<br />

pieces. In general laminating, where limited clamping<br />

pressure is used, sliced veneers are easier to hold in<br />

place and require fewer staples.<br />

Few lumberyards sell sliced veneers. In fact, so far<br />

as we know, you will have to order veneers from the<br />

companies that cut them. This sole source situati<strong>on</strong><br />

works well for those who can use fairly large quantities<br />

of veneer because manufacturers’ prices are usually low.<br />

Sliced veneers are comm<strong>on</strong>ly sold by the square foot<br />

(in 1985, 1,000 square feet of 1 ⁄8" cedar veneer cost $450)<br />

and are shipped in flitches—bundles 1' to 18" wide.<br />

Each flitch c<strong>on</strong>tains from 500 to 1,000 square feet of<br />

veneer. Smaller quantities, as might be needed for a<br />

dinghy, can be more expensive to buy and ship.<br />

Sliced veneers up to 17' l<strong>on</strong>g are usually available, but<br />

12' pieces are adequate for most laminating. Pieces less<br />

than 12' l<strong>on</strong>g can be used less wastefully in smaller<br />

boats. Widths are random in all lengths, but generally<br />

range between 6" and 12". As we explain in later