The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 13 – Synthetic Fibers and <strong>WEST</strong> <strong>SYSTEM</strong> ® <strong>Epoxy</strong> 123<br />

lightly. <str<strong>on</strong>g>The</str<strong>on</strong>g>n do a more thorough job <strong>on</strong> all puttied areas<br />

until you have removed the fuzzy feel of the cured epoxy<br />

and the filled spots are fair and smooth. We usually use<br />

a 2,000 rpm electric polisher with a 7" soft foam disc<br />

pad and 80-grit aluminum oxide paper for this job,<br />

but a sanding block and 50 or 80-grit paper will also<br />

work. Vacuum or sweep the surface to remove all<br />

residue. Particles the size of sand granules can help<br />

trap air between substrate and cloth and cause serious<br />

b<strong>on</strong>ding problems.<br />

Applying Fabric<br />

All fabrics can be applied to surfaces in <strong>on</strong>e of three<br />

general methods. <str<strong>on</strong>g>The</str<strong>on</strong>g> dry method, applying fabric to<br />

a dry surface, has several advantages. <str<strong>on</strong>g>The</str<strong>on</strong>g> fabric is easy<br />

to c<strong>on</strong>trol and, because you can use limited quantities<br />

of epoxy at any time, there is no rush. It is an easier<br />

method for <strong>on</strong>e pers<strong>on</strong> to manage. Applying fiberglass<br />

where a clear finish is desired, such as stripper canoes<br />

and kayaks, requires some special c<strong>on</strong>siderati<strong>on</strong>s and a<br />

variati<strong>on</strong> of the dry method. <str<strong>on</strong>g>The</str<strong>on</strong>g> dry method for clear<br />

finishes uses <strong>WEST</strong> <strong>SYSTEM</strong> 105 Resin combined with<br />

207 Special Coating Hardener. <str<strong>on</strong>g>The</str<strong>on</strong>g> 105 Resin/207<br />

Hardener combinati<strong>on</strong> is preferable for areas that will<br />

be naturally finished for both the dry method and the<br />

wet method.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> dry method will not work <strong>on</strong> overhead and vertical<br />

surfaces, so in those areas, you need to rely <strong>on</strong> a wet<br />

method, that is, applying fabric to a surface coated<br />

with wet epoxy. With the wet method, speed is of some<br />

importance because the timing of the operati<strong>on</strong> is<br />

affected by the initial surface coating. This method can<br />

be tricky, especially overhead, and may require the<br />

organized efforts of two or three people.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> Dry Method<br />

If the surface is fairly flat, lay the cut cloth over it and<br />

smooth all wrinkles. Use staples or masking tape to<br />

hold it in place, slightly overlapping any cloth joints.<br />

When the material is in positi<strong>on</strong>, pour mixed epoxy<br />

directly <strong>on</strong> the fabric. Begin by mixing small quantities<br />

of epoxy and increase batch size as you gain more<br />

experience. Use a flexible plastic spreader or squeegee<br />

to spread the epoxy and to remove any pools which<br />

form. Firm pressure is necessary, but d<strong>on</strong>’t press so<br />

hard that you shift the cloth.<br />

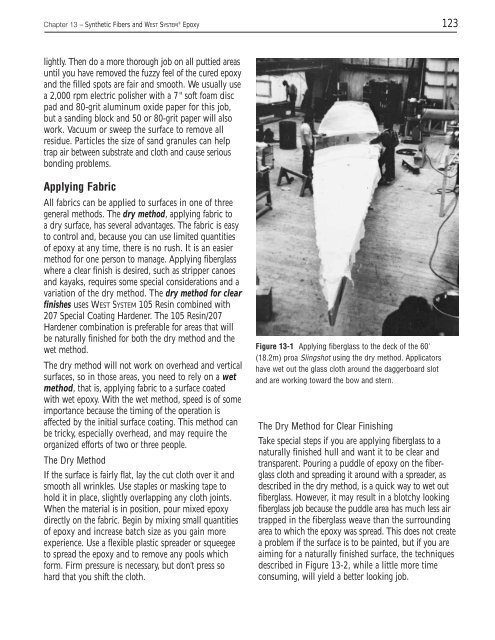

Figure 13-1 Applying fiberglass to the deck of the 60'<br />

(18.2m) proa Slingshot using the dry method. Applicators<br />

have wet out the glass cloth around the daggerboard slot<br />

and are working toward the bow and stern.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> Dry Method for Clear Finishing<br />

Take special steps if you are applying fiberglass to a<br />

naturally finished hull and want it to be clear and<br />

transparent. Pouring a puddle of epoxy <strong>on</strong> the fiberglass<br />

cloth and spreading it around with a spreader, as<br />

described in the dry method, is a quick way to wet out<br />

fiberglass. However, it may result in a blotchy looking<br />

fiberglass job because the puddle area has much less air<br />

trapped in the fiberglass weave than the surrounding<br />

area to which the epoxy was spread. This does not create<br />

a problem if the surface is to be painted, but if you are<br />

aiming for a naturally finished surface, the techniques<br />

described in Figure 13-2, while a little more time<br />

c<strong>on</strong>suming, will yield a better looking job.