The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

204 First Producti<strong>on</strong> Steps<br />

To detect twist, hold the spirit level in a vertical positi<strong>on</strong><br />

in various locati<strong>on</strong>s <strong>on</strong> the stati<strong>on</strong> face. If you have<br />

applied the legs precisely parallel to the centerline, you<br />

can use the legs as the arbitrarily chosen points to be<br />

made plumb. To eliminate twist, you usually need to<br />

adjust the diag<strong>on</strong>al or to install a sec<strong>on</strong>d, and sometimes<br />

even a third, diag<strong>on</strong>al.<br />

If the set-up is <strong>on</strong> a floor, you can use wooden wedges,<br />

tapped under the legs with a mallet or manually, for<br />

minute increments of vertical adjustment. If the set-up<br />

is <strong>on</strong> a str<strong>on</strong>gback, you can make these adjustments in<br />

the clamping of the legs to the anchoring blocks. Vertical<br />

adjustment usually necessitates adjustment of the<br />

diag<strong>on</strong>al(s) to bring the stati<strong>on</strong> back to plumb and the<br />

taking up or letting out of line to the plumb bob. Keep<br />

working until the stati<strong>on</strong> positi<strong>on</strong> is accurate. One<br />

adjustment may necessitate others.<br />

If you are using the two-level method instead of a plumb<br />

bob, you will need a sec<strong>on</strong>d spirit level. Clamp this<br />

horiz<strong>on</strong>tally al<strong>on</strong>g the spall. <str<strong>on</strong>g>The</str<strong>on</strong>g> straightness of the spall<br />

edge is obviously very important. With the two-level<br />

method, bringing the bubble of the sec<strong>on</strong>d level into the<br />

reticles takes the place of bringing the plumb line over<br />

the stati<strong>on</strong>’s centerline. Bringing the straightedge to the<br />

cable then performs the functi<strong>on</strong> of aligning the centerline<br />

<strong>on</strong>to the cable. <str<strong>on</strong>g>The</str<strong>on</strong>g> other level is used as before.<br />

Orient the level that is clamped to the spall in the same<br />

directi<strong>on</strong> <strong>on</strong> all the frames. In other words, if the frames<br />

are being set up in a north-south directi<strong>on</strong> athwartship,<br />

mark <strong>on</strong>e end of the level “N” or “S” and always<br />

positi<strong>on</strong> it accordingly. In this way, any error in the<br />

level will always be in the same directi<strong>on</strong> and the result<br />

will be that all of the stati<strong>on</strong> centerlines, though they<br />

may not be perfectly vertical, will at least be in the<br />

same plane, which is all that really matters.<br />

Before applying any filleting, it is a good idea to go to<br />

the lofting floor and measure and make notes <strong>on</strong> the<br />

distances for each stati<strong>on</strong> of the cable to sheer and the<br />

cable to the top of the mold frame. After a stati<strong>on</strong> is in<br />

positi<strong>on</strong>, check the measurements in the set-up before<br />

applying the filleting. <str<strong>on</strong>g>The</str<strong>on</strong>g> check is good for revealing<br />

any gross errors in manufacturing or setting up the<br />

frame. Such errors would reveal themselves rather so<strong>on</strong><br />

in any case, but it is better to discover them before it<br />

becomes necessary to chisel away the filleting material<br />

in order to correct them.<br />

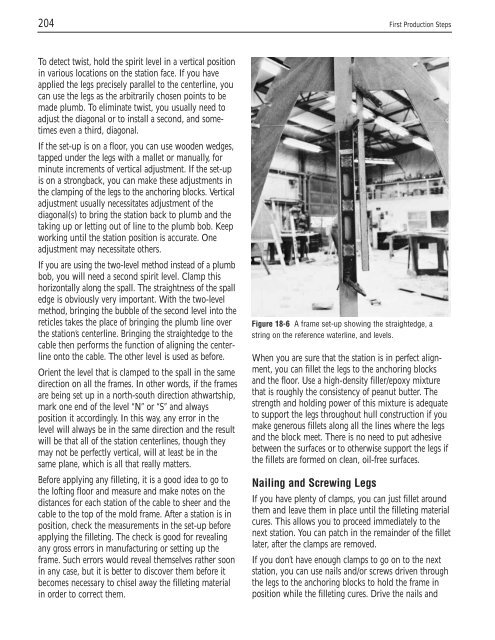

Figure 18-6 A frame set-up showing the straightedge, a<br />

string <strong>on</strong> the reference waterline, and levels.<br />

When you are sure that the stati<strong>on</strong> is in perfect alignment,<br />

you can fillet the legs to the anchoring blocks<br />

and the floor. Use a high-density filler/epoxy mixture<br />

that is roughly the c<strong>on</strong>sistency of peanut butter. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

strength and holding power of this mixture is adequate<br />

to support the legs throughout hull c<strong>on</strong>structi<strong>on</strong> if you<br />

make generous fillets al<strong>on</strong>g all the lines where the legs<br />

and the block meet. <str<strong>on</strong>g>The</str<strong>on</strong>g>re is no need to put adhesive<br />

between the surfaces or to otherwise support the legs if<br />

the fillets are formed <strong>on</strong> clean, oil-free surfaces.<br />

Nailing and Screwing Legs<br />

If you have plenty of clamps, you can just fillet around<br />

them and leave them in place until the filleting material<br />

cures. This allows you to proceed immediately to the<br />

next stati<strong>on</strong>. You can patch in the remainder of the fillet<br />

later, after the clamps are removed.<br />

If you d<strong>on</strong>’t have enough clamps to go <strong>on</strong> to the next<br />

stati<strong>on</strong>, you can use nails and/or screws driven through<br />

the legs to the anchoring blocks to hold the frame in<br />

positi<strong>on</strong> while the filleting cures. Drive the nails and