The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

132 Core <strong>Boat</strong>building Techniques<br />

may be higher than the value derived above, but we<br />

recommend using the c<strong>on</strong>servative value for estimati<strong>on</strong>.<br />

For most applicati<strong>on</strong>s where the shear strength of the<br />

wood is greater than 800 psi, we recommend a hole<br />

sized 1 ⁄4" (6mm) larger in diameter than the major<br />

diameter of the bolt. This gives an epoxy annulus of<br />

1 ⁄8" (3mm) around the bolt. We vary the length of the<br />

bolt and depth of the hole to balance the breaking<br />

strength of the bolt versus the withdrawal resistance<br />

of the epoxy plug. <str<strong>on</strong>g>The</str<strong>on</strong>g> 800 psi epoxy shear strength<br />

is the limiting value.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> following example shows how to determine the<br />

diameter and depth of an oversize hole so that the force<br />

required to extract the fastener is approximately equal<br />

to the breaking strength of the bolt:<br />

A 3 ⁄8" diameter 18-8 stainless-steel bolt with an ultimate<br />

tensile strength of 85,000 psi and an effective crosssecti<strong>on</strong>al<br />

working area of 0.0775 square inches has<br />

a breaking strength of 6,587 pounds. <str<strong>on</strong>g>The</str<strong>on</strong>g> hole depth<br />

should be the breaking strength (6,600 pounds)<br />

divided by the epoxy shear strength (800 psi), divided<br />

by the circumference of the hole (0.625" � 3.1416 =<br />

1.9635") to equal 4.20". In actual practice, we used<br />

a 5 ⁄8" diameter hole with a depth of 41 ⁄2" for a 3 ⁄8"<br />

diameter bolt with 41 ⁄4" inches of b<strong>on</strong>ded length.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> above calculati<strong>on</strong>s need to be modified when you<br />

are limited in the depth of the hole allowed or when<br />

a short or oversized bolt is specified in the hardware<br />

installati<strong>on</strong>. You do not want to cut away large porti<strong>on</strong>s<br />

of a keel or floor by using a grossly oversized hole.<br />

Likewise, you may be limited in a deck applicati<strong>on</strong> by<br />

blocking locati<strong>on</strong> or overhead space limitati<strong>on</strong>s. In such<br />

cases, it is best to use the 1 ⁄4" larger diameter, epoxyfilled<br />

hole to assist in stabilizing and securing the keel<br />

bolt, but use floors or metal pads to distribute the load.<br />

How the surface area of the hole affects small and large<br />

fasteners is discussed below.<br />

Small fasteners in tensi<strong>on</strong><br />

In 1978 and 1979, we c<strong>on</strong>ducted tests to determine<br />

the relative effects of surface area <strong>on</strong> fasteners. We<br />

compared tensi<strong>on</strong> withdrawal of 11 ⁄2" l<strong>on</strong>g flathead<br />

wood screws, ranging in size from No. 8 through No.<br />

14, in dry pilot holes and oversize holes from 3 ⁄16" to 3 ⁄4"<br />

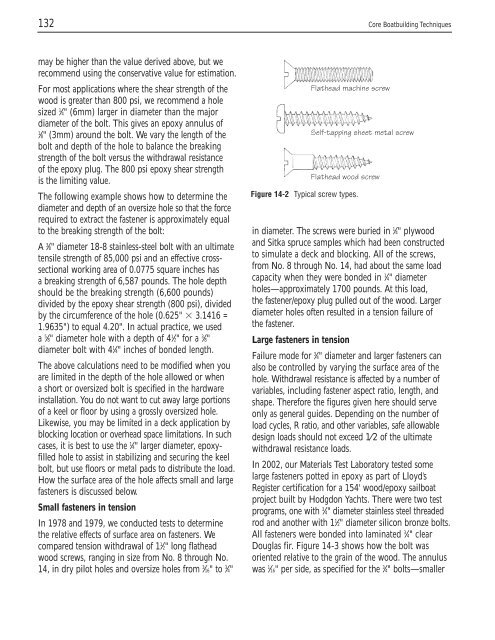

Flathead machine screw<br />

Figure 14-2 Typical screw types.<br />

Self-tapping sheet metal screw<br />

Flathead wood screw<br />

in diameter. <str<strong>on</strong>g>The</str<strong>on</strong>g> screws were buried in 1 ⁄4" plywood<br />

and Sitka spruce samples which had been c<strong>on</strong>structed<br />

to simulate a deck and blocking. All of the screws,<br />

from No. 8 through No. 14, had about the same load<br />

capacity when they were b<strong>on</strong>ded in 1 ⁄4" diameter<br />

holes—approximately 1700 pounds. At this load,<br />

the fastener/epoxy plug pulled out of the wood. Larger<br />

diameter holes often resulted in a tensi<strong>on</strong> failure of<br />

the fastener.<br />

Large fasteners in tensi<strong>on</strong><br />

Failure mode for 3 ⁄4" diameter and larger fasteners can<br />

also be c<strong>on</strong>trolled by varying the surface area of the<br />

hole. Withdrawal resistance is affected by a number of<br />

variables, including fastener aspect ratio, length, and<br />

shape. <str<strong>on</strong>g>The</str<strong>on</strong>g>refore the figures given here should serve<br />

<strong>on</strong>ly as general guides. Depending <strong>on</strong> the number of<br />

load cycles, R ratio, and other variables, safe allowable<br />

design loads should not exceed 1⁄2 of the ultimate<br />

withdrawal resistance loads.<br />

In 2002, our Materials Test Laboratory tested some<br />

large fasteners potted in epoxy as part of Lloyd’s<br />

Register certificati<strong>on</strong> for a 154' wood/epoxy sailboat<br />

project built by Hodgd<strong>on</strong> Yachts. <str<strong>on</strong>g>The</str<strong>on</strong>g>re were two test<br />

programs, <strong>on</strong>e with 3 ⁄4" diameter stainless steel threaded<br />

rod and another with 11 ⁄2" diameter silic<strong>on</strong> br<strong>on</strong>ze bolts.<br />

All fasteners were b<strong>on</strong>ded into laminated 3 ⁄4" clear<br />

Douglas fir. Figure 14-3 shows how the bolt was<br />

oriented relative to the grain of the wood. <str<strong>on</strong>g>The</str<strong>on</strong>g> annulus<br />

was 1 ⁄16" per side, as specified for the 3 ⁄4" bolts—smaller