The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 8 – Tools and the <strong>Boat</strong>shop 61<br />

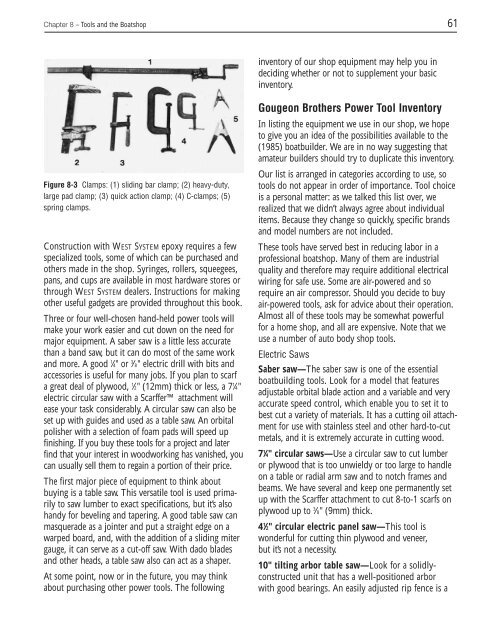

Figure 8-3 Clamps: (1) sliding bar clamp; (2) heavy-duty,<br />

large pad clamp; (3) quick acti<strong>on</strong> clamp; (4) C-clamps; (5)<br />

spring clamps.<br />

C<strong>on</strong>structi<strong>on</strong> with <strong>WEST</strong> <strong>SYSTEM</strong> epoxy requires a few<br />

specialized tools, some of which can be purchased and<br />

others made in the shop. Syringes, rollers, squeegees,<br />

pans, and cups are available in most hardware stores or<br />

through <strong>WEST</strong> <strong>SYSTEM</strong> dealers. Instructi<strong>on</strong>s for making<br />

other useful gadgets are provided throughout this book.<br />

Three or four well-chosen hand-held power tools will<br />

make your work easier and cut down <strong>on</strong> the need for<br />

major equipment. A saber saw is a little less accurate<br />

than a band saw, but it can do most of the same work<br />

and more. A good 1 ⁄4" or 3 ⁄8" electric drill with bits and<br />

accessories is useful for many jobs. If you plan to scarf<br />

a great deal of plywood, 1 ⁄2" (12mm) thick or less, a 71 ⁄4"<br />

electric circular saw with a Scarffer attachment will<br />

ease your task c<strong>on</strong>siderably. A circular saw can also be<br />

set up with guides and used as a table saw. An orbital<br />

polisher with a selecti<strong>on</strong> of foam pads will speed up<br />

finishing. If you buy these tools for a project and later<br />

find that your interest in woodworking has vanished, you<br />

can usually sell them to regain a porti<strong>on</strong> of their price.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> first major piece of equipment to think about<br />

buying is a table saw. This versatile tool is used primarily<br />

to saw lumber to exact specificati<strong>on</strong>s, but it’s also<br />

handy for beveling and tapering. A good table saw can<br />

masquerade as a jointer and put a straight edge <strong>on</strong> a<br />

warped board, and, with the additi<strong>on</strong> of a sliding miter<br />

gauge, it can serve as a cut-off saw. With dado blades<br />

and other heads, a table saw also can act as a shaper.<br />

At some point, now or in the future, you may think<br />

about purchasing other power tools. <str<strong>on</strong>g>The</str<strong>on</strong>g> following<br />

inventory of our shop equipment may help you in<br />

deciding whether or not to supplement your basic<br />

inventory.<br />

<str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Brothers</str<strong>on</strong>g> Power Tool Inventory<br />

In listing the equipment we use in our shop, we hope<br />

to give you an idea of the possibilities available to the<br />

(1985) boatbuilder. We are in no way suggesting that<br />

amateur builders should try to duplicate this inventory.<br />

Our list is arranged in categories according to use, so<br />

tools do not appear in order of importance. Tool choice<br />

is a pers<strong>on</strong>al matter: as we talked this list over, we<br />

realized that we didn’t always agree about individual<br />

items. Because they change so quickly, specific brands<br />

and model numbers are not included.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>se tools have served best in reducing labor in a<br />

professi<strong>on</strong>al boatshop. Many of them are industrial<br />

quality and therefore may require additi<strong>on</strong>al electrical<br />

wiring for safe use. Some are air-powered and so<br />

require an air compressor. Should you decide to buy<br />

air-powered tools, ask for advice about their operati<strong>on</strong>.<br />

Almost all of these tools may be somewhat powerful<br />

for a home shop, and all are expensive. Note that we<br />

use a number of auto body shop tools.<br />

Electric Saws<br />

Saber saw—<str<strong>on</strong>g>The</str<strong>on</strong>g> saber saw is <strong>on</strong>e of the essential<br />

boatbuilding tools. Look for a model that features<br />

adjustable orbital blade acti<strong>on</strong> and a variable and very<br />

accurate speed c<strong>on</strong>trol, which enable you to set it to<br />

best cut a variety of materials. It has a cutting oil attachment<br />

for use with stainless steel and other hard-to-cut<br />

metals, and it is extremely accurate in cutting wood.<br />

71 ⁄4" circular saws—Use a circular saw to cut lumber<br />

or plywood that is too unwieldy or too large to handle<br />

<strong>on</strong> a table or radial arm saw and to notch frames and<br />

beams. We have several and keep <strong>on</strong>e permanently set<br />

up with the Scarffer attachment to cut 8-to-1 scarfs <strong>on</strong><br />

plywood up to 3 ⁄8" (9mm) thick.<br />

41 ⁄2" circular electric panel saw—This tool is<br />

w<strong>on</strong>derful for cutting thin plywood and veneer,<br />

but it’s not a necessity.<br />

10" tilting arbor table saw—Look for a solidlyc<strong>on</strong>structed<br />

unit that has a well-positi<strong>on</strong>ed arbor<br />

with good bearings. An easily adjusted rip fence is a