The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

290 Hull C<strong>on</strong>structi<strong>on</strong> Methods<br />

Composite Chine C<strong>on</strong>structi<strong>on</strong><br />

Many smaller boats and some larger <strong>on</strong>es have been<br />

built with no chine log at all. Instead, the plywood<br />

panels are joined with a composite chine made of fiberglass<br />

cloth or tape as shown in Figure 24-10. This is<br />

also referred to as stitch-and-glue c<strong>on</strong>structi<strong>on</strong>. It is<br />

frequently used in kit boats, such as kayaks and small<br />

craft. A variety of stitch-and-glue plans are also now<br />

available for drift boats, car toppers, power, and<br />

sailboats. Some are well over 20' (6m) in length. In<br />

most cases, especially with thinner plywood, it’s easy to<br />

manufacture a fiberglass joint between two plywood<br />

panels that is str<strong>on</strong>ger than the plywood.<br />

Stitch-and-glue is a method where plywood panels are<br />

cut into specific shapes that eventually get c<strong>on</strong>nected<br />

together al<strong>on</strong>g the keel, chines, stems, and transom to<br />

create specific hull forms. <str<strong>on</strong>g>The</str<strong>on</strong>g> panels are pulled into<br />

shape with pieces of soft wire (or plastic wire ties) that<br />

are fed through matching holes drilled al<strong>on</strong>g the edges<br />

of the mating panels. Each twisted wire or plastic wire<br />

tie forms another “stitch” al<strong>on</strong>g the joint. In simple<br />

designs, the panels can be c<strong>on</strong>nected together without<br />

elaborate mold frames or stringers. In larger designs,<br />

permanent or temporary frames are required to help<br />

define the shape. <str<strong>on</strong>g>The</str<strong>on</strong>g>se are typically few in number as<br />

the panels end up being quite stiff when bent and<br />

c<strong>on</strong>nected al<strong>on</strong>g the joints. Gaps of up to 1 ⁄4" (6mm) are<br />

acceptable as the joint will be filled with a generous<br />

fillet of thickened epoxy prior to being glassed over.<br />

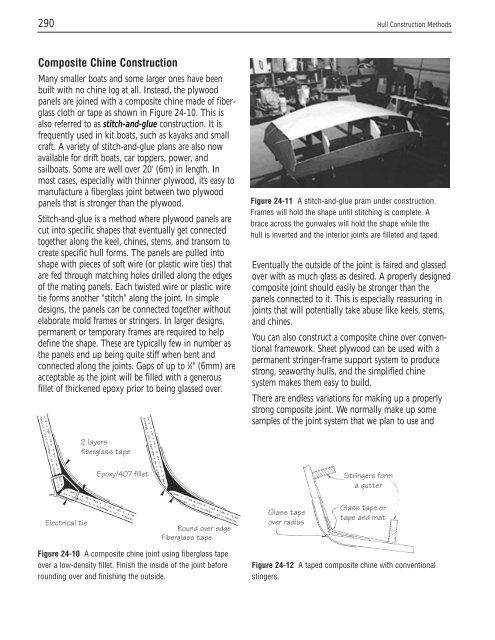

Electrical tie<br />

2 layers<br />

fiberglass tape<br />

<strong>Epoxy</strong>/407 fillet<br />

Round over edge<br />

Fiberglass tape<br />

Figure 24-10 A composite chine joint using fiberglass tape<br />

over a low-density fillet. Finish the inside of the joint before<br />

rounding over and finishing the outside.<br />

Figure 24-11 A stitch-and-glue pram under c<strong>on</strong>structi<strong>on</strong>.<br />

Frames will hold the shape until stitching is complete. A<br />

brace across the gunwales will hold the shape while the<br />

hull is inverted and the interior joints are filleted and taped.<br />

Eventually the outside of the joint is faired and glassed<br />

over with as much glass as desired. A properly designed<br />

composite joint should easily be str<strong>on</strong>ger than the<br />

panels c<strong>on</strong>nected to it. This is especially reassuring in<br />

joints that will potentially take abuse like keels, stems,<br />

and chines.<br />

You can also c<strong>on</strong>struct a composite chine over c<strong>on</strong>venti<strong>on</strong>al<br />

framework. Sheet plywood can be used with a<br />

permanent stringer-frame support system to produce<br />

str<strong>on</strong>g, seaworthy hulls, and the simplified chine<br />

system makes them easy to build.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are endless variati<strong>on</strong>s for making up a properly<br />

str<strong>on</strong>g composite joint. We normally make up some<br />

samples of the joint system that we plan to use and<br />

Glass tape<br />

over radius<br />

Stringers form<br />

a gutter<br />

Glass tape or<br />

tape and mat<br />

Figure 24-12 A taped composite chine with c<strong>on</strong>venti<strong>on</strong>al<br />

stingers.