The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

84 Getting Started<br />

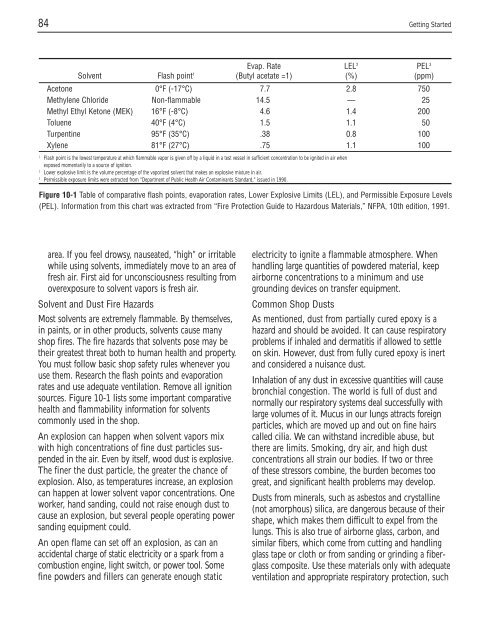

Evap. Rate LEL2 PEL3 Solvent Flash point1 (Butyl acetate =1) (%) (ppm)<br />

Acet<strong>on</strong>e 0°F (-17°C) 7.7 2.8 750<br />

Methylene Chloride N<strong>on</strong>-flammable 14.5 — 25<br />

Methyl Ethyl Ket<strong>on</strong>e (MEK) 16°F (-8°C) 4.6 1.4 200<br />

Toluene 40°F (4°C) 1.5 1.1 50<br />

Turpentine 95°F (35°C) .38 0.8 100<br />

Xylene 81°F (27°C) .75 1.1 100<br />

1 Flash point is the lowest temperature at which flammable vapor is given off by a liquid in a test vessel in sufficient c<strong>on</strong>centrati<strong>on</strong> to be ignited in air when<br />

exposed momentarily to a source of igniti<strong>on</strong>.<br />

2 Lower explosive limit is the volume percentage of the vaporized solvent that makes an explosive mixture in air.<br />

3 Permissible exposure limits were extracted from “Department of Public Health Air C<strong>on</strong>taminants Standard,” issued in 1990.<br />

Figure 10-1 Table of comparative flash points, evaporati<strong>on</strong> rates, Lower Explosive Limits (LEL), and Permissible Exposure Levels<br />

(PEL). Informati<strong>on</strong> from this chart was extracted from “Fire Protecti<strong>on</strong> Guide to Hazardous Materials,” NFPA, 10th editi<strong>on</strong>, 1991.<br />

area. If you feel drowsy, nauseated, “high” or irritable<br />

while using solvents, immediately move to an area of<br />

fresh air. First aid for unc<strong>on</strong>sciousness resulting from<br />

overexposure to solvent vapors is fresh air.<br />

Solvent and Dust Fire Hazards<br />

Most solvents are extremely flammable. By themselves,<br />

in paints, or in other products, solvents cause many<br />

shop fires. <str<strong>on</strong>g>The</str<strong>on</strong>g> fire hazards that solvents pose may be<br />

their greatest threat both to human health and property.<br />

You must follow basic shop safety rules whenever you<br />

use them. Research the flash points and evaporati<strong>on</strong><br />

rates and use adequate ventilati<strong>on</strong>. Remove all igniti<strong>on</strong><br />

sources. Figure 10-1 lists some important comparative<br />

health and flammability informati<strong>on</strong> for solvents<br />

comm<strong>on</strong>ly used in the shop.<br />

An explosi<strong>on</strong> can happen when solvent vapors mix<br />

with high c<strong>on</strong>centrati<strong>on</strong>s of fine dust particles suspended<br />

in the air. Even by itself, wood dust is explosive.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> finer the dust particle, the greater the chance of<br />

explosi<strong>on</strong>. Also, as temperatures increase, an explosi<strong>on</strong><br />

can happen at lower solvent vapor c<strong>on</strong>centrati<strong>on</strong>s. One<br />

worker, hand sanding, could not raise enough dust to<br />

cause an explosi<strong>on</strong>, but several people operating power<br />

sanding equipment could.<br />

An open flame can set off an explosi<strong>on</strong>, as can an<br />

accidental charge of static electricity or a spark from a<br />

combusti<strong>on</strong> engine, light switch, or power tool. Some<br />

fine powders and fillers can generate enough static<br />

electricity to ignite a flammable atmosphere. When<br />

handling large quantities of powdered material, keep<br />

airborne c<strong>on</strong>centrati<strong>on</strong>s to a minimum and use<br />

grounding devices <strong>on</strong> transfer equipment.<br />

Comm<strong>on</strong> Shop Dusts<br />

As menti<strong>on</strong>ed, dust from partially cured epoxy is a<br />

hazard and should be avoided. It can cause respiratory<br />

problems if inhaled and dermatitis if allowed to settle<br />

<strong>on</strong> skin. However, dust from fully cured epoxy is inert<br />

and c<strong>on</strong>sidered a nuisance dust.<br />

Inhalati<strong>on</strong> of any dust in excessive quantities will cause<br />

br<strong>on</strong>chial c<strong>on</strong>gesti<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g> world is full of dust and<br />

normally our respiratory systems deal successfully with<br />

large volumes of it. Mucus in our lungs attracts foreign<br />

particles, which are moved up and out <strong>on</strong> fine hairs<br />

called cilia. We can withstand incredible abuse, but<br />

there are limits. Smoking, dry air, and high dust<br />

c<strong>on</strong>centrati<strong>on</strong>s all strain our bodies. If two or three<br />

of these stressors combine, the burden becomes too<br />

great, and significant health problems may develop.<br />

Dusts from minerals, such as asbestos and crystalline<br />

(not amorphous) silica, are dangerous because of their<br />

shape, which makes them difficult to expel from the<br />

lungs. This is also true of airborne glass, carb<strong>on</strong>, and<br />

similar fibers, which come from cutting and handling<br />

glass tape or cloth or from sanding or grinding a fiberglass<br />

composite. Use these materials <strong>on</strong>ly with adequate<br />

ventilati<strong>on</strong> and appropriate respiratory protecti<strong>on</strong>, such