The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

168 First Producti<strong>on</strong> Steps<br />

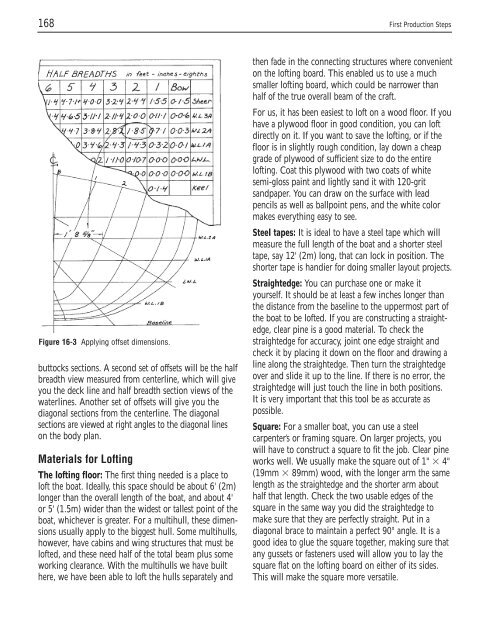

Figure 16-3 Applying offset dimensi<strong>on</strong>s.<br />

buttocks secti<strong>on</strong>s. A sec<strong>on</strong>d set of offsets will be the half<br />

breadth view measured from centerline, which will give<br />

you the deck line and half breadth secti<strong>on</strong> views of the<br />

waterlines. Another set of offsets will give you the<br />

diag<strong>on</strong>al secti<strong>on</strong>s from the centerline. <str<strong>on</strong>g>The</str<strong>on</strong>g> diag<strong>on</strong>al<br />

secti<strong>on</strong>s are viewed at right angles to the diag<strong>on</strong>al lines<br />

<strong>on</strong> the body plan.<br />

Materials for Lofting<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> lofting floor: <str<strong>on</strong>g>The</str<strong>on</strong>g> first thing needed is a place to<br />

loft the boat. Ideally, this space should be about 6' (2m)<br />

l<strong>on</strong>ger than the overall length of the boat, and about 4'<br />

or 5' (1.5m) wider than the widest or tallest point of the<br />

boat, whichever is greater. For a multihull, these dimensi<strong>on</strong>s<br />

usually apply to the biggest hull. Some multihulls,<br />

however, have cabins and wing structures that must be<br />

lofted, and these need half of the total beam plus some<br />

working clearance. With the multihulls we have built<br />

here, we have been able to loft the hulls separately and<br />

then fade in the c<strong>on</strong>necting structures where c<strong>on</strong>venient<br />

<strong>on</strong> the lofting board. This enabled us to use a much<br />

smaller lofting board, which could be narrower than<br />

half of the true overall beam of the craft.<br />

For us, it has been easiest to loft <strong>on</strong> a wood floor. If you<br />

have a plywood floor in good c<strong>on</strong>diti<strong>on</strong>, you can loft<br />

directly <strong>on</strong> it. If you want to save the lofting, or if the<br />

floor is in slightly rough c<strong>on</strong>diti<strong>on</strong>, lay down a cheap<br />

grade of plywood of sufficient size to do the entire<br />

lofting. Coat this plywood with two coats of white<br />

semi-gloss paint and lightly sand it with 120-grit<br />

sandpaper. You can draw <strong>on</strong> the surface with lead<br />

pencils as well as ballpoint pens, and the white color<br />

makes everything easy to see.<br />

Steel tapes: It is ideal to have a steel tape which will<br />

measure the full length of the boat and a shorter steel<br />

tape, say 12' (2m) l<strong>on</strong>g, that can lock in positi<strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

shorter tape is handier for doing smaller layout projects.<br />

Straightedge: You can purchase <strong>on</strong>e or make it<br />

yourself. It should be at least a few inches l<strong>on</strong>ger than<br />

the distance from the baseline to the uppermost part of<br />

the boat to be lofted. If you are c<strong>on</strong>structing a straightedge,<br />

clear pine is a good material. To check the<br />

straightedge for accuracy, joint <strong>on</strong>e edge straight and<br />

check it by placing it down <strong>on</strong> the floor and drawing a<br />

line al<strong>on</strong>g the straightedge. <str<strong>on</strong>g>The</str<strong>on</strong>g>n turn the straightedge<br />

over and slide it up to the line. If there is no error, the<br />

straightedge will just touch the line in both positi<strong>on</strong>s.<br />

It is very important that this tool be as accurate as<br />

possible.<br />

Square: For a smaller boat, you can use a steel<br />

carpenter’s or framing square. On larger projects, you<br />

will have to c<strong>on</strong>struct a square to fit the job. Clear pine<br />

works well. We usually make the square out of 1" � 4"<br />

(19mm � 89mm) wood, with the l<strong>on</strong>ger arm the same<br />

length as the straightedge and the shorter arm about<br />

half that length. Check the two usable edges of the<br />

square in the same way you did the straightedge to<br />

make sure that they are perfectly straight. Put in a<br />

diag<strong>on</strong>al brace to maintain a perfect 90° angle. It is a<br />

good idea to glue the square together, making sure that<br />

any gussets or fasteners used will allow you to lay the<br />

square flat <strong>on</strong> the lofting board <strong>on</strong> either of its sides.<br />

This will make the square more versatile.