The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

206 First Producti<strong>on</strong> Steps<br />

Beveling<br />

Frames are beveled so that planking can bend evenly,<br />

with smooth curves, over them. Begin this operati<strong>on</strong> by<br />

rolling flat black paint <strong>on</strong> the edges of the frames. Most<br />

of this paint will be planed away; the object is to leave<br />

a thin line of black <strong>on</strong> the c<strong>on</strong>trolling edge so that you<br />

know it has not been disturbed.<br />

Use a batten that spans at least three stati<strong>on</strong>s as a guide<br />

for beveling. Lay it over three frames and nail down its<br />

ends. If your mold frames are <strong>on</strong>ly 1 ⁄4" (6mm) thick,<br />

you can just hack away excess stock from the middle<br />

frame. If they are thicker, take a handsaw and cut<br />

marks <strong>on</strong> the edge of the middle frame <strong>on</strong> either side of<br />

the batten parallel to it as it crosses the frame edge at an<br />

angle. Cut no deeper than the black c<strong>on</strong>trol edge. Move<br />

the batten up and down the frame, sawing or hacking<br />

every foot al<strong>on</strong>g its edge. Check for fairness. When you<br />

have finished <strong>on</strong>e frame, move <strong>on</strong> to the next.<br />

When all larger frames are marked, chisel away the<br />

wood between the kerfs so that you have a series of<br />

notches. Check again for fairness, and then scribble<br />

across the bottom of each notch with a pencil. Using<br />

the pencil marks to guide you, plane the entire edge of<br />

the frame. We use power planes to rough-cut bevels,<br />

but advise against them unless you have some experience<br />

with these machines. Hand planes do just as well,<br />

though at a somewhat slower rate.<br />

Fairing<br />

Once you have rough cut the bevels so that <strong>on</strong>ly a thin<br />

line of black remains <strong>on</strong> the c<strong>on</strong>trolling edges, you are<br />

ready for final fairing. As in lofting, the eye and artistic<br />

sensitivity are the main tools. <str<strong>on</strong>g>The</str<strong>on</strong>g> object is to make the<br />

l<strong>on</strong>g batten touch all the c<strong>on</strong>trolling edges under it and<br />

form a curve free of lumps or flat spots in all positi<strong>on</strong>s<br />

<strong>on</strong> the length of the set-up.<br />

To accomplish this, it may be necessary to cut below<br />

the marked black c<strong>on</strong>trol edge in some areas, and to<br />

build up above the edge in others by b<strong>on</strong>ding <strong>on</strong> strips<br />

of wood or not beveling to the full depth of the saw<br />

cuts. Accurate work in lofting, picking up, cutting<br />

frames, c<strong>on</strong>structing them, and setting them up will<br />

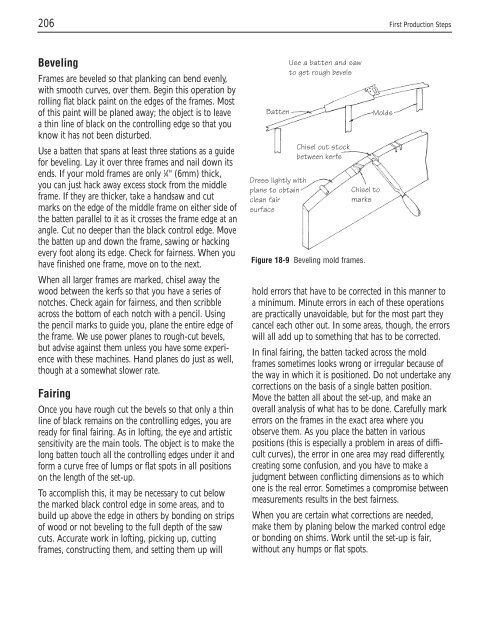

Use a batten and saw<br />

to get rough bevels<br />

Batten Molds<br />

Dress lightly with<br />

plane to obtain<br />

clean fair<br />

surface<br />

Chisel out stock<br />

between kerfs<br />

Chisel to<br />

marks<br />

Figure 18-9 Beveling mold frames.<br />

hold errors that have to be corrected in this manner to<br />

a minimum. Minute errors in each of these operati<strong>on</strong>s<br />

are practically unavoidable, but for the most part they<br />

cancel each other out. In some areas, though, the errors<br />

will all add up to something that has to be corrected.<br />

In final fairing, the batten tacked across the mold<br />

frames sometimes looks wr<strong>on</strong>g or irregular because of<br />

the way in which it is positi<strong>on</strong>ed. Do not undertake any<br />

correcti<strong>on</strong>s <strong>on</strong> the basis of a single batten positi<strong>on</strong>.<br />

Move the batten all about the set-up, and make an<br />

overall analysis of what has to be d<strong>on</strong>e. Carefully mark<br />

errors <strong>on</strong> the frames in the exact area where you<br />

observe them. As you place the batten in various<br />

positi<strong>on</strong>s (this is especially a problem in areas of difficult<br />

curves), the error in <strong>on</strong>e area may read differently,<br />

creating some c<strong>on</strong>fusi<strong>on</strong>, and you have to make a<br />

judgment between c<strong>on</strong>flicting dimensi<strong>on</strong>s as to which<br />

<strong>on</strong>e is the real error. Sometimes a compromise between<br />

measurements results in the best fairness.<br />

When you are certain what correcti<strong>on</strong>s are needed,<br />

make them by planing below the marked c<strong>on</strong>trol edge<br />

or b<strong>on</strong>ding <strong>on</strong> shims. Work until the set-up is fair,<br />

without any humps or flat spots.