The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 14 – Hardware B<strong>on</strong>ding 131<br />

side, created by drilling a fastener hole with a bit<br />

about 1 ⁄4" (6mm) larger in diameter than the fastener.<br />

Drill the wood to the proper depth, fill the hole with<br />

epoxy, coat the shank and threads of the fastener<br />

with epoxy, and set it in.<br />

Oversize holes and epoxy interfaces between metal<br />

fasteners and wood fibers become increasingly<br />

important with fasteners which are larger than 1 ⁄4"<br />

in diameter. This is particularly true in situati<strong>on</strong>s<br />

where the potential of a bolt, machine screw, or<br />

threaded rod must be maximized.<br />

3. B<strong>on</strong>d the c<strong>on</strong>tact surface of the fitting to wood<br />

fiber with epoxy. B<strong>on</strong>ding the c<strong>on</strong>tact surface of<br />

a fitting can c<strong>on</strong>tribute a great deal to load distributi<strong>on</strong><br />

over maximum wood surface. Proper b<strong>on</strong>ding<br />

of a 21 ⁄2" diameter pad eye, for example, can add<br />

up to 7,000 pounds of extra shear-load resistance,<br />

assuming Sitka spruce with the load parallel to grain.<br />

We are primarily interested in improving the shearload<br />

capacity of hardware installati<strong>on</strong>s. It’s difficult<br />

to make significant shear-load improvements by<br />

b<strong>on</strong>ding fasteners, but when a fitting is b<strong>on</strong>ded to<br />

the wood <strong>on</strong> which it sits, it has far more capacity<br />

in shear than the fasteners used to attach the item<br />

have by themselves. We b<strong>on</strong>d hardware mainly to<br />

improve shear strength, the main weakness of lowdensity<br />

woods.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> Design Process for Fastener B<strong>on</strong>ding<br />

Hardware b<strong>on</strong>ding is a predictable process that allows<br />

a designer or engineer to determine in advance how a<br />

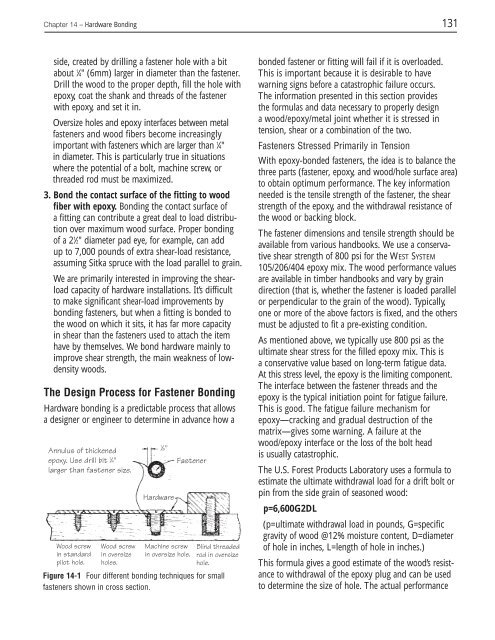

Annulus of thickened<br />

epoxy. Use drill bit 1 ⁄4"<br />

larger than fastener size.<br />

Wood screw<br />

in standard<br />

pilot hole.<br />

Wood screw<br />

in oversize<br />

holes.<br />

Figure 14-1 Four different b<strong>on</strong>ding techniques for small<br />

fasteners shown in cross secti<strong>on</strong>.<br />

1 ⁄8"<br />

Hardware<br />

Fastener<br />

Machine screw<br />

in oversize hole.<br />

Blind threaded<br />

rod in oversize<br />

hole.<br />

b<strong>on</strong>ded fastener or fitting will fail if it is overloaded.<br />

This is important because it is desirable to have<br />

warning signs before a catastrophic failure occurs.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> informati<strong>on</strong> presented in this secti<strong>on</strong> provides<br />

the formulas and data necessary to properly design<br />

a wood/epoxy/metal joint whether it is stressed in<br />

tensi<strong>on</strong>, shear or a combinati<strong>on</strong> of the two.<br />

Fasteners Stressed Primarily in Tensi<strong>on</strong><br />

With epoxy-b<strong>on</strong>ded fasteners, the idea is to balance the<br />

three parts (fastener, epoxy, and wood/hole surface area)<br />

to obtain optimum performance. <str<strong>on</strong>g>The</str<strong>on</strong>g> key informati<strong>on</strong><br />

needed is the tensile strength of the fastener, the shear<br />

strength of the epoxy, and the withdrawal resistance of<br />

the wood or backing block.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> fastener dimensi<strong>on</strong>s and tensile strength should be<br />

available from various handbooks. We use a c<strong>on</strong>servative<br />

shear strength of 800 psi for the <strong>WEST</strong> <strong>SYSTEM</strong><br />

105/206/404 epoxy mix. <str<strong>on</strong>g>The</str<strong>on</strong>g> wood performance values<br />

are available in timber handbooks and vary by grain<br />

directi<strong>on</strong> (that is, whether the fastener is loaded parallel<br />

or perpendicular to the grain of the wood). Typically,<br />

<strong>on</strong>e or more of the above factors is fixed, and the others<br />

must be adjusted to fit a pre-existing c<strong>on</strong>diti<strong>on</strong>.<br />

As menti<strong>on</strong>ed above, we typically use 800 psi as the<br />

ultimate shear stress for the filled epoxy mix. This is<br />

a c<strong>on</strong>servative value based <strong>on</strong> l<strong>on</strong>g-term fatigue data.<br />

At this stress level, the epoxy is the limiting comp<strong>on</strong>ent.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> interface between the fastener threads and the<br />

epoxy is the typical initiati<strong>on</strong> point for fatigue failure.<br />

This is good. <str<strong>on</strong>g>The</str<strong>on</strong>g> fatigue failure mechanism for<br />

epoxy—cracking and gradual destructi<strong>on</strong> of the<br />

matrix—gives some warning. A failure at the<br />

wood/epoxy interface or the loss of the bolt head<br />

is usually catastrophic.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> U.S. Forest Products Laboratory uses a formula to<br />

estimate the ultimate withdrawal load for a drift bolt or<br />

pin from the side grain of seas<strong>on</strong>ed wood:<br />

p=6,600G2DL<br />

(p=ultimate withdrawal load in pounds, G=specific<br />

gravity of wood @12% moisture c<strong>on</strong>tent, D=diameter<br />

of hole in inches, L=length of hole in inches.)<br />

This formula gives a good estimate of the wood’s resistance<br />

to withdrawal of the epoxy plug and can be used<br />

to determine the size of hole. <str<strong>on</strong>g>The</str<strong>on</strong>g> actual performance